Method for performing industrialized production on moxifloxacin hydrochloride

A technology of moxifloxacin hydrochloride and sodium chloride, applied in the field of industrialized production of moxifloxacin hydrochloride

Active Publication Date: 2011-06-15

NANJING YOKO PHARMA

View PDF3 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method has never been used in the synthesis of moxifloxacin hydrochloride

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for synthesizing moxifloxacin hydrochloride. The method is characterized in that: moxifloxacin hydrochloride is precipitated from solution according to solubility difference of the moxifloxacin hydrochloride in sodium chloride solution with different concentrations so as to fulfill the aim of separation. The method particularly comprises the following steps of: adding sodium chloride into moxifloxacin hydrochloride-containing aqueous solution; stirring to crystallize; filtering; drying; recrystallizing with water; filtering; and drying to obtain the moxifloxacin hydrochloride. The method is simple and convenient in operation; the product has high purity; a single impurity is less than 0.1 percent; the total impurities are less than 0.2 percent; and the method is suitable for industrialized production.

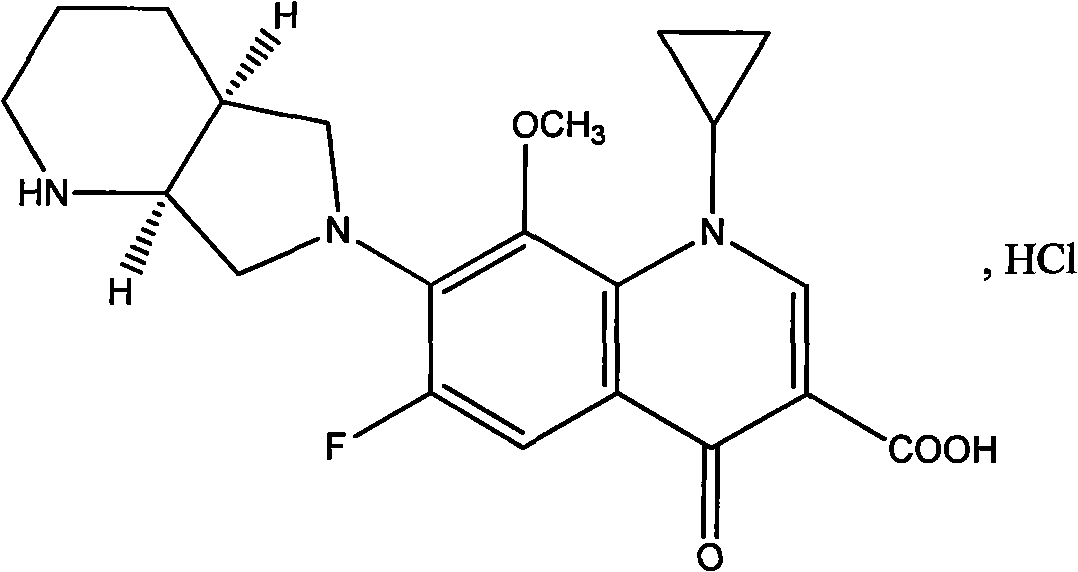

Description

A kind of method of industrialized production moxifloxacin hydrochloride technical field The invention relates to an industrialized method for producing moxifloxacin hydrochloride. Moxifloxacin hydrochloride is a fluoroquinolone antibiotic that can be used to treat infections caused by sensitive bacteria. Formula I technical background Moxifloxacinhydrochloride (Moxifloxacinhydrochloride) is an extended-spectrum quinolone antibiotic developed by Bayer, and its chemical name is: 1-cyclopropyl-6-fluoro-1,4-dihydro-8-methoxy-7-[( 4αS,7αS)-octahydro-6H-pyrrolo[3,4-b]pyridin-6-yl]-4-oxo-3-quinolinecarboxylate hydrochloride. Its chemical structural formula is shown in Formula 1. Moxifloxacin hydrochloride was first listed in Germany in September 1999, and was approved by FDA in December 1999 for listing in the United States. On the basis of maintaining the excellent activity of fluoroquinolones against gram-negative bacteria in the early stage, the activity against gram-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07D471/04

Inventor 叶海晁阳梁静陈爱萍刘雪曹卫陈雷

Owner NANJING YOKO PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com