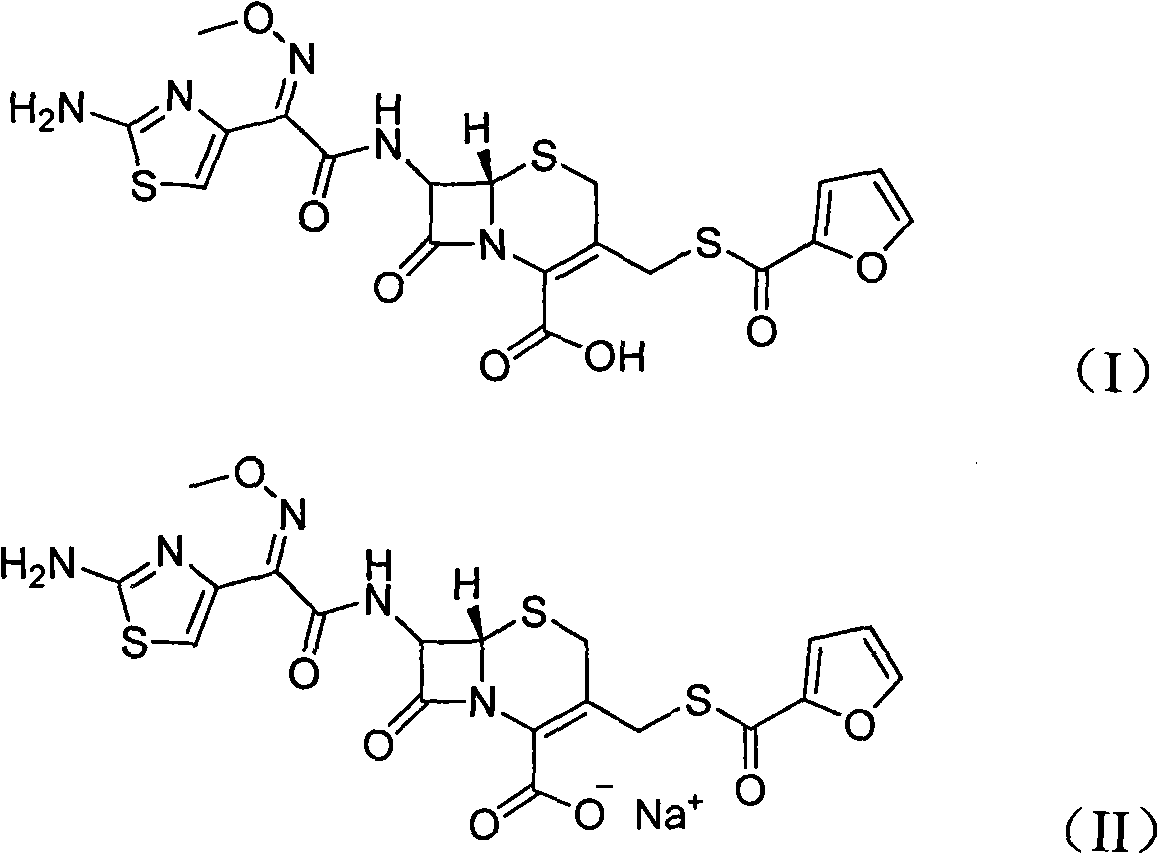

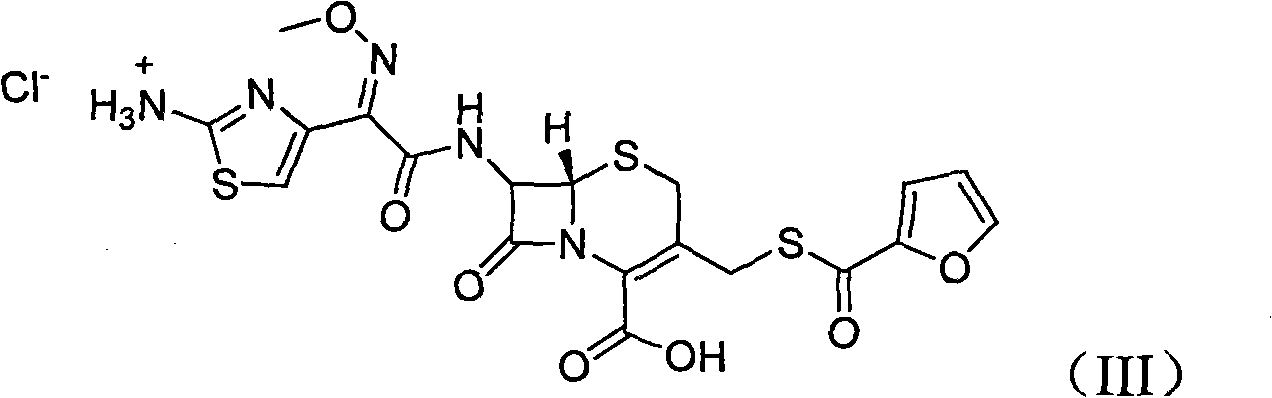

New preparation method of ceftiofur sodium

A technology of ceftiofur sodium and ceftiofur sodium, which is applied in the field of preparation of ceftiofur sodium, can solve the problems of reduced production cost, low product yield, low purity, etc., achieves reduced production cost, simple operation, and improved reaction yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 2.00g of ceftiofur hydrochloride and 30ml of ethylene glycol monomethyl ether into a 50ml single-necked bottle, stir until completely dissolved, accurately weigh 1.00g of sodium bicarbonate, add it to the system, stir and react until no gas is released, Suction filtration under reduced pressure, pour the filtrate into 400ml tetrahydrofuran, stir for 2 hours until the crystallization is complete, suction filtration, wash the filter cake with acetone, and vacuum dry at room temperature until no more weight loss. 1.73 g of off-white solid was obtained. (The HPLC area normalization method shows that the purity is greater than 98.0%, the HPLC external standard method determines the content is greater than 95.0%, and other indicators of the product meet the quality standards of the Ministry of Agriculture)

Embodiment 2

[0030] Add 2.00g of ceftiofur hydrochloride and 30ml of ethylene glycol monoethyl ether into a 50ml single-necked bottle, stir until completely dissolved, accurately weigh 0.60g of sodium carbonate, add it to the system, stir and react until no gas is released, and decompress Suction filtration, pour the filtrate into 400ml of acetone, stir for 2 hours until the crystallization is complete, suction filtration, wash the filter cake with acetone, and vacuum dry at room temperature until no more weight loss. 1.69 g of off-white solid was obtained. (The HPLC area normalization method shows that the purity is greater than 98.0%, the HPLC external standard method determines the content is greater than 95.0%, and other indicators of the product meet the quality standards of the Ministry of Agriculture)

Embodiment 3

[0032] Add 2.00g of ceftiofur hydrochloride and 30ml of dimethylformamide into a 50ml single-necked bottle, stir until completely dissolved, accurately weigh 1.80g of sodium 2-ethylhexanoate, add it to the system, stir for 2 hours, and depressurize Suction filtration, pour the filtrate into 400ml of ethanol, stir for 2 hours until the crystallization is complete, suction filtration, wash the filter cake with acetone, and vacuum dry at room temperature until no more weight loss. 1.72 g of off-white solid was obtained. (The HPLC area normalization method shows that the purity is greater than 98.0%, the HPLC external standard method determines the content is greater than 95.0%, and other indicators of the product meet the quality standards of the Ministry of Agriculture)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com