Process for parkerising internal surface of long thin steel tube with manganese phosphate

A surface manganese phosphate phosphorus treatment process technology, applied in the direction of metal material coating process, etc., can solve the problems of poor treatment quality, poor phosphating quality, difficult phosphating time, etc., to achieve wide practical value and sufficient sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

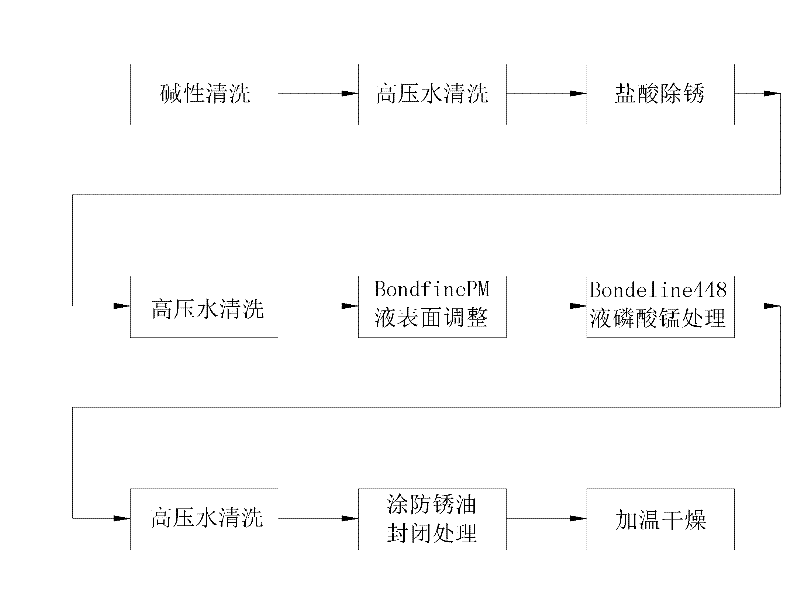

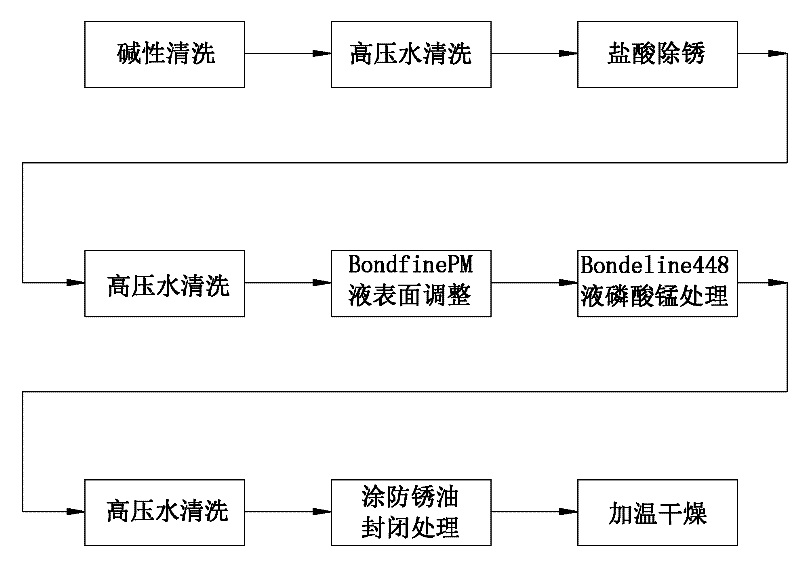

[0035] The details of the present invention will be further described below in conjunction with the drawings.

[0036] A manganese phosphate phosphate treatment process for the surface of a slender steel pipe, which is characterized in:

[0037] The first way: alkaline cleaning

[0038] Step 2: High-pressure water cleaning 2 times

[0039] The third course: 5% hydrochloric acid rust removal

[0040] Step 4: High-pressure water cleaning

[0041] Step 5: Perform surface adjustment in Bondfine PM solution for 0.5 to 1 minute

[0042] Lane 6: Manganese phosphate film treatment in Bondeline 448 solution, the solution concentration: 5.8%

[0043] Temperature: 93~97℃

[0044] Soaking time: 8-20 minutes

[0045] Total acidity: 24~26ml

[0046] Free acidity: 2~3ml

[0047] The ratio of total acid / free acid: 6.8:1

[0048] Iron metal composition: 0.2~0.3%

[0049] Soaking tank: 304 / 316 stainless steel

[0050] Step 7: 2 times of high pressure water cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com