Boiler soot blowing control device based on flue fly ash mass flow

A mass flow, boiler soot blowing technology, applied in thermal power engineering and its automation field, can solve the problems of increased contamination model error, poor stability and adaptability, poor real-time performance, etc., to save maintenance workload and improve boiler efficiency , the effect of reducing boiler failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

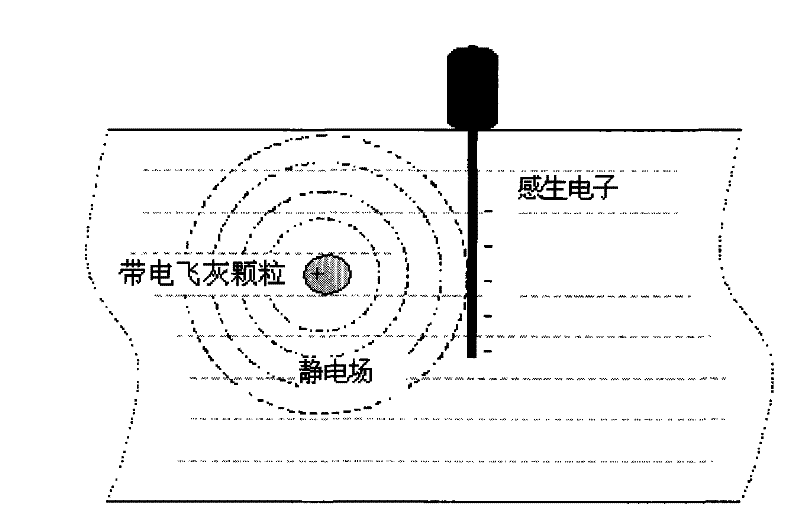

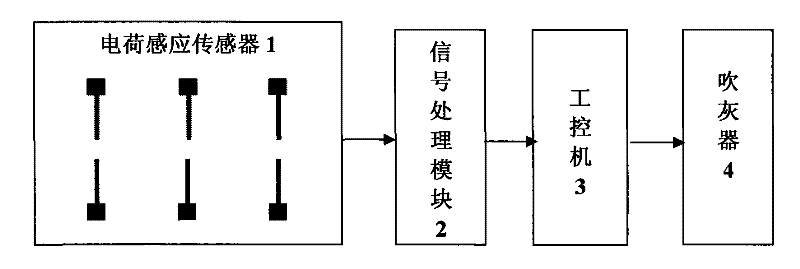

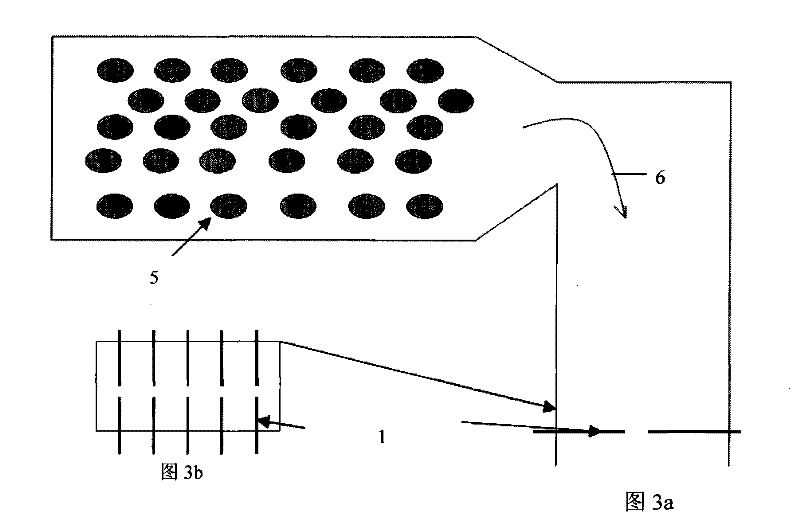

[0038] Such as figure 1 As shown, during the pneumatic conveying process of the fly ash particles in the flue, on the one hand, they will collide, rub and separate with the flue wall, and on the other hand, there will also be collision, friction and separation between the fly ash particles. Such a large number of close contact and separation processes can make fly ash particles carry a considerable amount of electrostatic charge. The charged fly ash particles will generate a certain electrostatic field. When the charged fly ash particles pass through the metal induction probe, the probe surface in the electrostatic field will generate an equal amount of induced charges, and absorb the charges by contacting the fly ash particles. When ash particles flow through the probe, a current is formed on the probe, and the magnitude of the current is related to the mass flow rate of the fly ash particles flowing through the probe. The induced current is used as the measurement signal, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com