Flat tube manufacturing method of microchannel heat exchanger

A technology of micro-channel heat exchanger and processing method, which can be applied to tubular elements, heat transfer modification, heat exchange equipment, etc., can solve problems such as poor refrigerant heat exchange, improve product market competitiveness and reduce resistance , the effect of sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

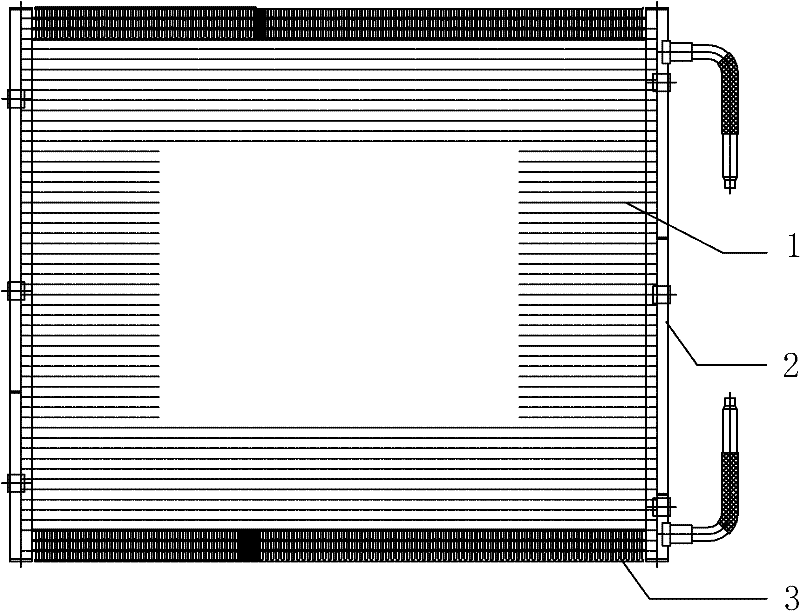

[0017] In order to improve the refrigeration capacity of the refrigeration system, it is the key to improve the heat exchange efficiency of the heat exchanger as much as possible. figure 1 As shown, the microchannel heat exchanger of the present invention is composed of an inlet tube, a microchannel flat tube bundle, a header 2, fins 3 and an outlet tube. The microchannel flat tube bundle is formed by connecting multiple flat tubes 1 side by side, and is located in a frame structure composed of left and right headers 2 and upper and lower fins 3 .

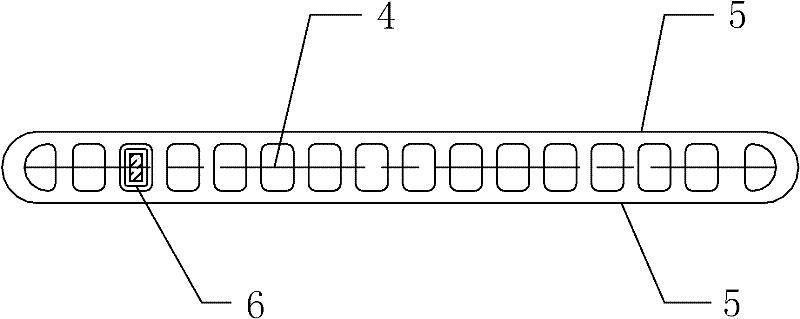

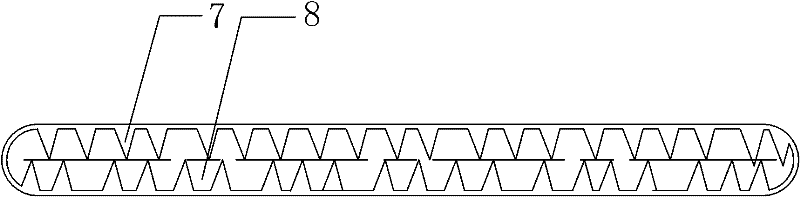

[0018] figure 2 Shown is a schematic diagram of the flat tube section structure of the existing microchannel flat tube bundle. The end faces of the flat tubes are arranged with holes, commonly known as "harmonica tubes". Flow and heat exchange in the harmonica tube microchannel 4 . The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com