Method, process and equipment for recycling low-temperature afterheat generated in roasting process of producing sulfuric acid from iron pyrite

A low-temperature waste heat and sulfuric acid roasting technology, applied in the field of low-temperature waste heat recovery, can solve the problems of positive pressure, deterioration of the operating environment, and influence on the boiling state of the fluidized fluidized furnace, etc., and achieve a significant effect of low-carbon economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The present invention takes the sulfuric acid production line with an annual output of 300,000 tons of Hunan Xinhengguang Technology Co., Ltd. as an example:

[0037] The production of sulfuric acid is 37.5 tons per hour.

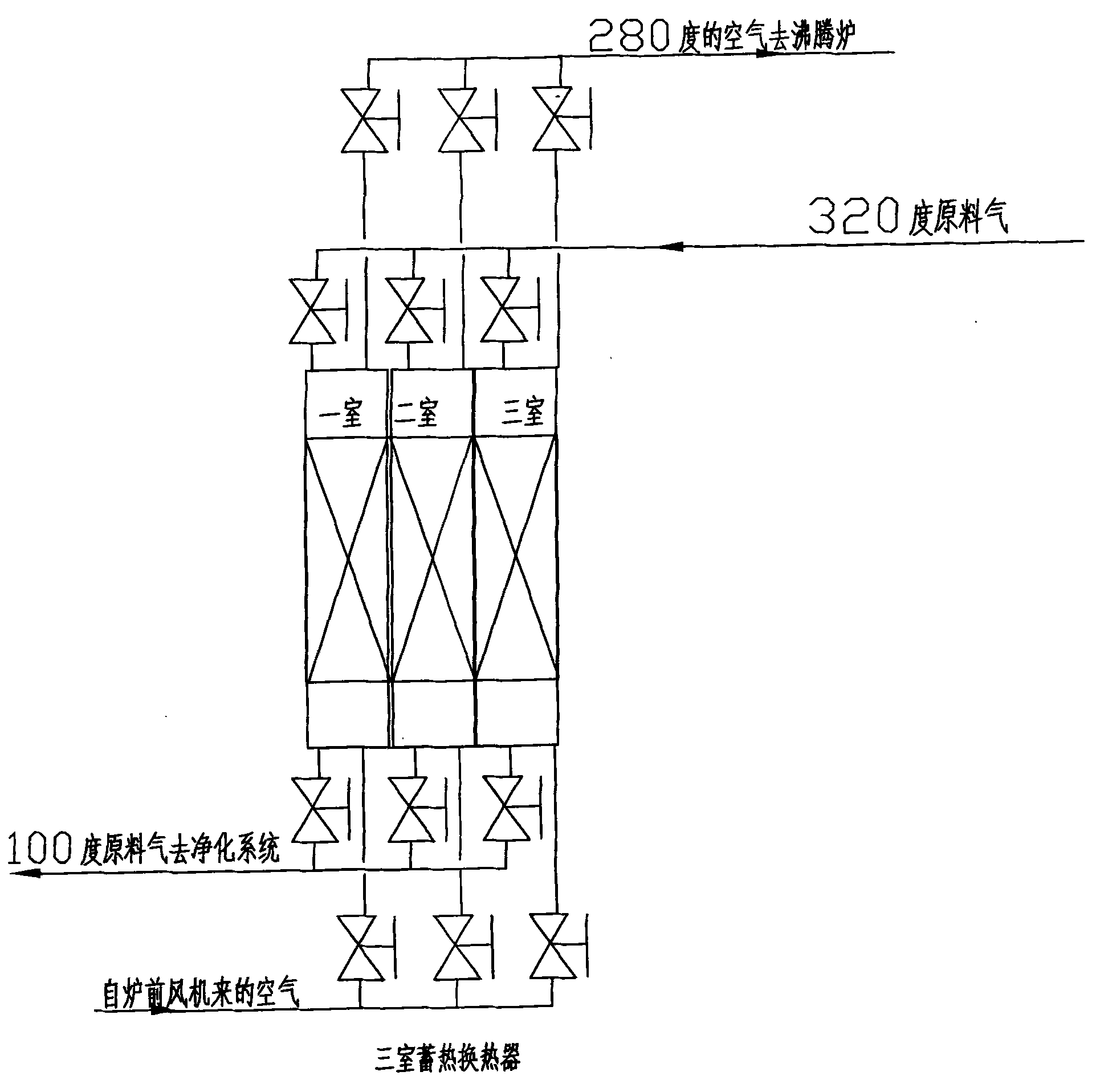

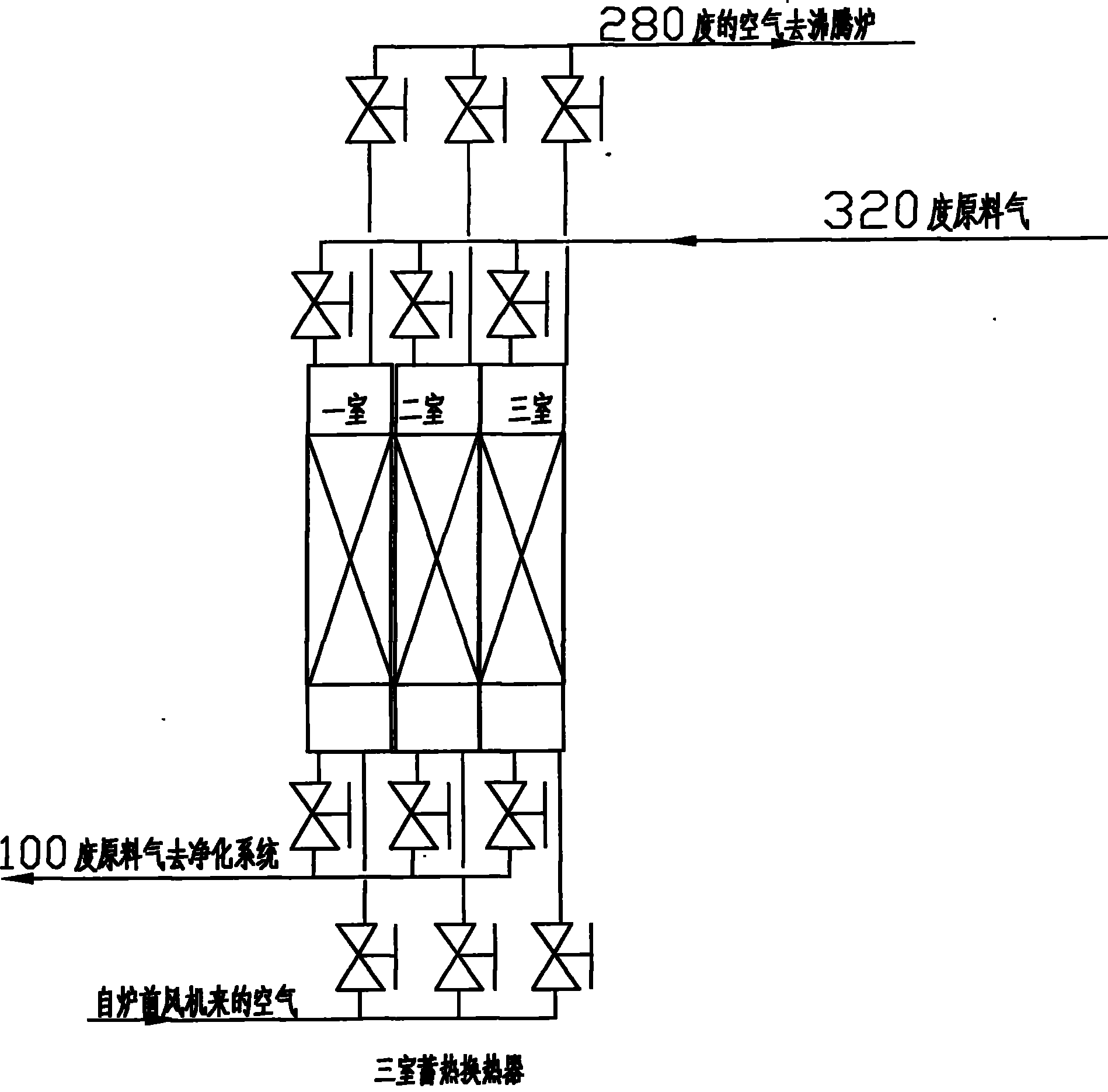

[0038] 1. The temperature of the electrostatic precipitator is about 320°C, and the gas volume is 74330Nm 3 / h, the heat brought by the raw material gas is about 10.68*10 6 kcal / h, the moisture content of the feed gas is generally 6.0% (volume content), the temperature drops to 100°C on average after passing through the three-chamber heat storage heat exchanger, and the average temperature of the air in front of the furnace is 280°C. Process recovery waste heat 5.7*10 6 kcal / h.

[0039] 2. Add a heat exchange chamber to the classic double-chamber regenerative heat exchanger to form a three-chamber regenerative heat exchanger. The volume of each heat exchange chamber is 36 cubic meters: 3000*2000*6000; it is loaded with 60 tons of acid-resistant h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com