Major accident mitigation system of nuclear power station on basis of nano fluid characteristic

A nanofluid and serious accident technology, which is applied in the field of nuclear power plant equipment technology and safety, can solve the problems of poor removal and purification of nanoscale particles, high toxicity of radioactive aerosol, and difficult to control and predict the impact, and achieve enhanced boiling heat transfer characteristics, the effect of reducing the hazards of radioactive particles, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

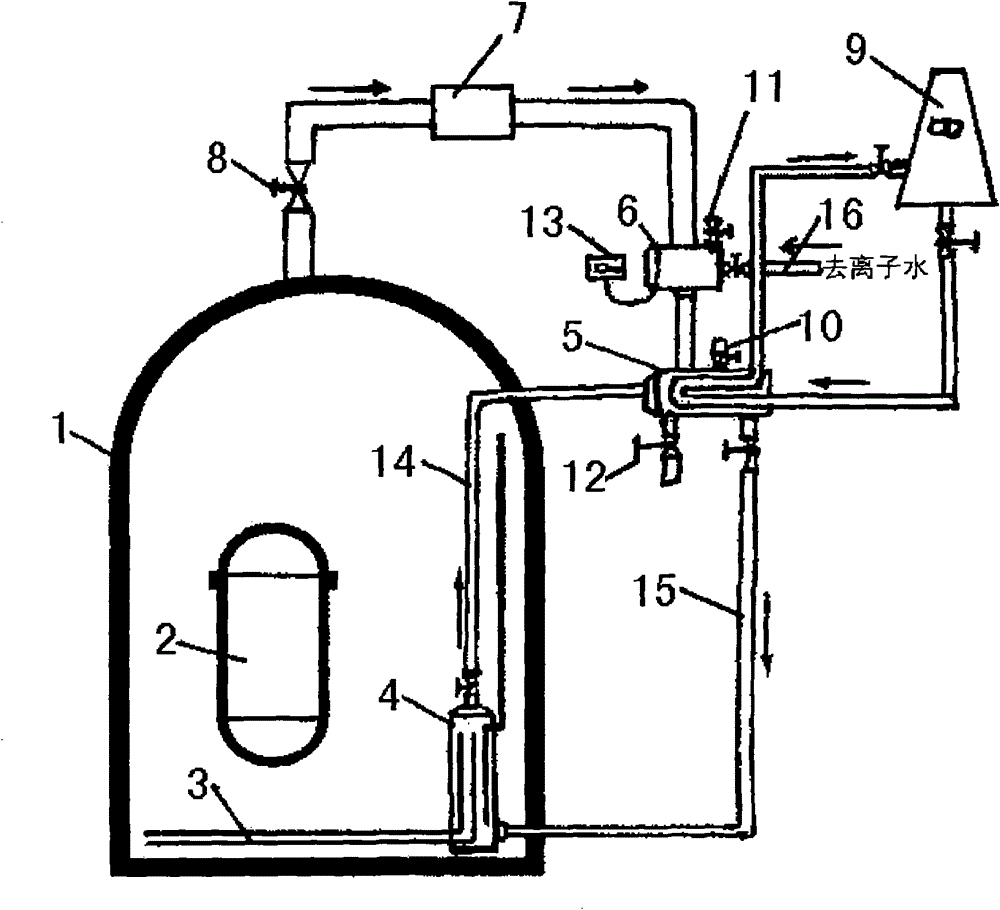

[0016] The invention provides a severe accident mitigation system of a nuclear power plant based on the characteristics of the nanometer fluid. Below in conjunction with accompanying drawing, concrete structure, working process of the present invention will be further described. figure 1 Among them, the superconducting heat pipe 3 is arranged on the side and bottom of the containment vessel 1, the superconducting heat pipe is arranged horizontally under the reactor 2, the heat exchanger 4 is fixed on the side and bottom of the containment vessel 1, and the horizontally arranged superconducting heat pipe is connected from the bottom of the heat exchanger 4 Insertion, the upper side of the heat exchanger 4 is inserted into the vertical superconducting heat pipe; the downcomer 15 and the riser 14 connected from the cooler 5 outside the containment vessel 1 pass through the containment vessel wall and connect with the lower part of the heat exchanger 4 respectively. It is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com