Silicon drift detector with curved surface structure

A silicon drift detector and curved surface technology, applied in semiconductor devices, radiation intensity measurement, sustainable manufacturing/processing, etc. Multiple applications, avoid punch-through effect, improve stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

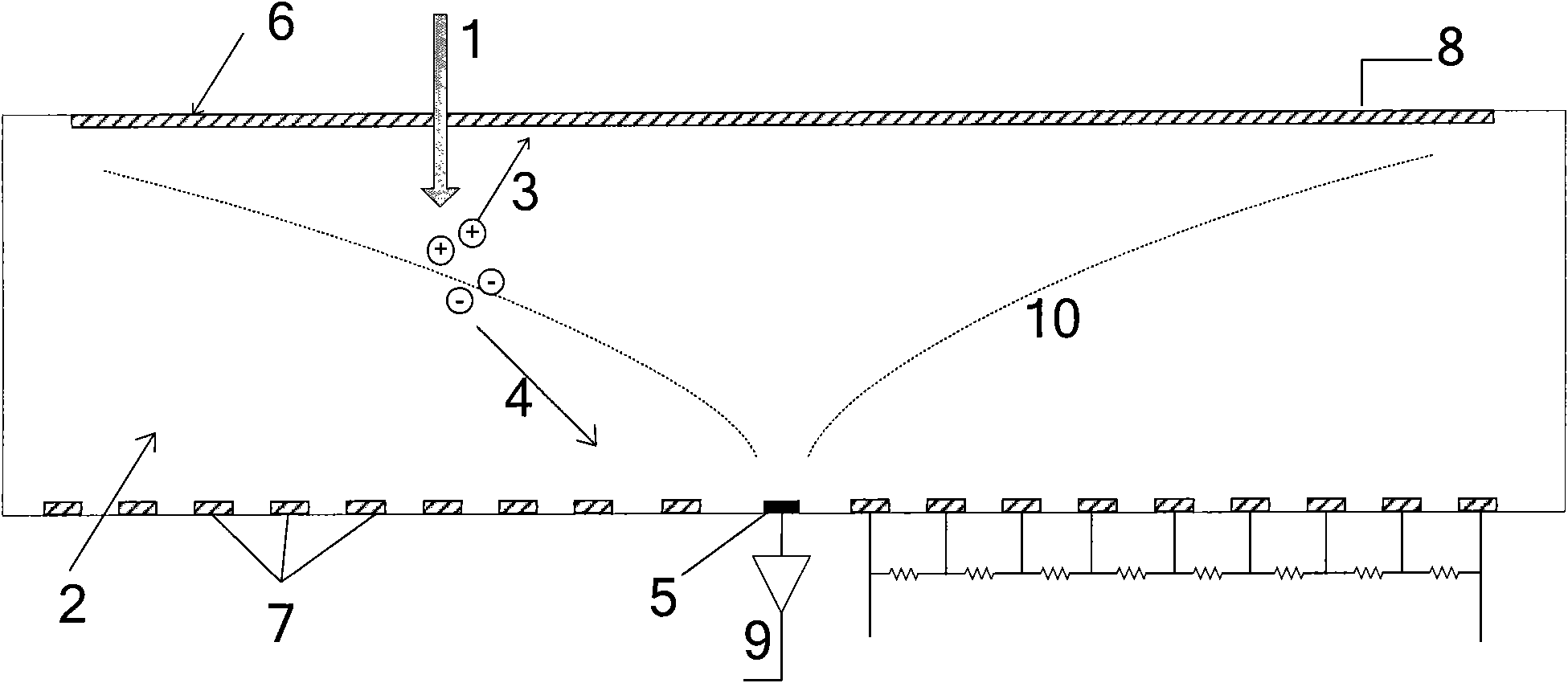

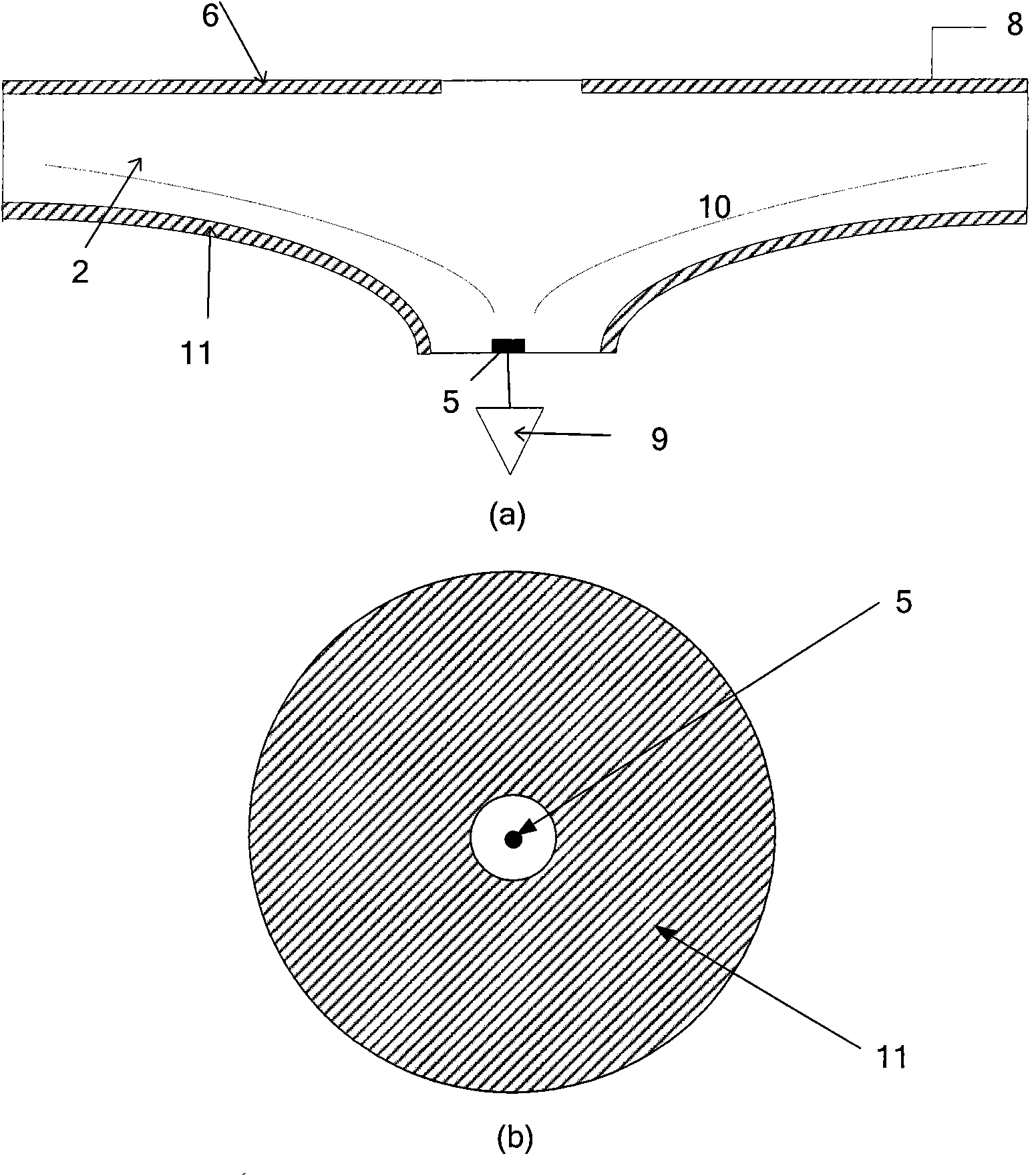

[0044] The following examples are intended to be manufactured by a specific manufacturing method figure 2 A silicon drift detector with a curved surface structure is shown.

[0045] Concrete manufacturing method comprises the following steps:

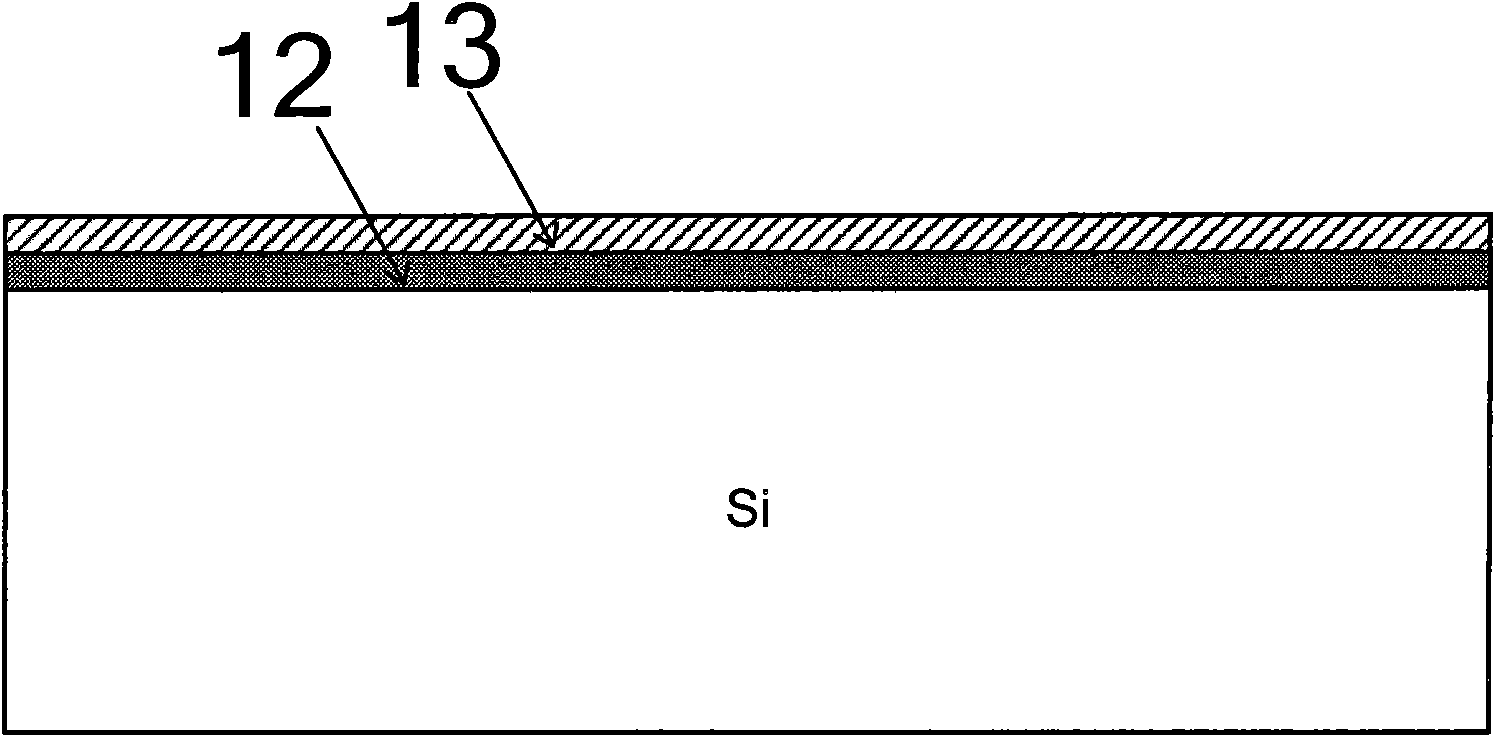

[0046] 1. If Figure 3-1 As shown, on the first surface of the high-resistance N-type silicon wafer as the substrate (ie Figure 3-1 Oxidation is carried out on the upper surface of the silicon drift detector, which is also the backside of the silicon drift detector finally made, to form a silicon dioxide layer 12 with a thickness of 1 μm; then chemical vapor deposition (LPCVD) with a thickness of for The silicon nitride layer 13;

[0047] 2. If Figure 3-2 As shown, photolithography is carried out on the surface of the silicon nitride layer 13, and the mask is etched, so as to obtain an expo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com