Micro inertial sensor with embedded transverse movable electrode

A moving electrode, lateral technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiments and drawings, but the present invention is by no means limited to the described embodiments.

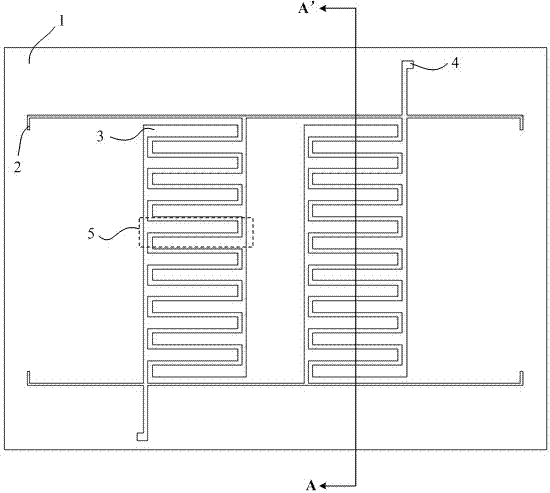

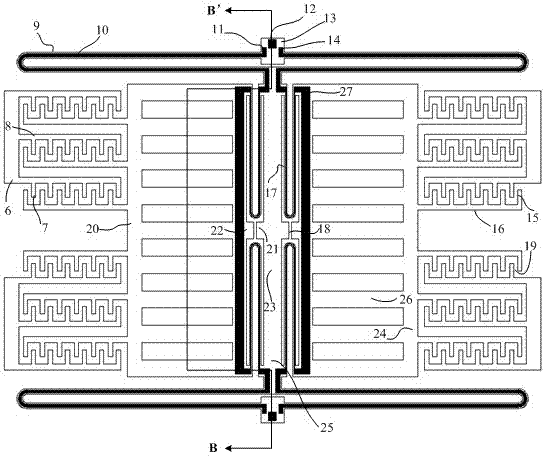

[0024] Refer to Figure 1 (a), Figure 1 (b), Figure 2 (a), Figure 2 (b), image 3 with Figure 4 , Form two sets of center-symmetrical interdigitated fixed counter electrodes for detection on the first substrate 1, corresponding to the connection coupling electrode 2 between the fixed masses, and the connection line connecting the coupling electrode 2 and the lead electrode 4. The interdigitated fixed counter electrode is composed of comb-teeth electrodes 3 and lead-out electrodes that intersect in the transverse direction; a sensor anchor 13 fixed on the first substrate 1 is formed on the second substrate, and the second substrate is suspended on the second substrate. A strip-shaped sensor mass 25 above the substrate 1, two U-shaped sensor support beams connecting the sensor anchor 13 and the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com