Method for preparing bi-component polyurethane pouring sealant and product thereof

A two-component polyurethane and potting adhesive technology, applied in the field of polyurethane, can solve problems such as poor insulation performance and potting restrictions, and achieve the effects of fast curing speed at low temperature, easy control of conditions, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing a two-component polyurethane encapsulant, comprising the following steps:

[0032] 1. Preparation of component A:

[0033] (1) add 40.0 grams of castor oil, 60.0 grams of polyoxypropylene triol (M=3000) in a dry and clean three-necked flask equipped with a thermometer, a stirring device, and a condenser, and vacuum dehydrate at 110° C. for two hours;

[0034] (2) Add 9.0 grams of flame retardant tris(2-chloropropyl) phosphate, 1.5 grams of EFKA defoamer 2720 (Ciba Efka defoamer 2720), and 1.5 grams of dibutyltin dilaurate when the temperature is lowered below 60 °C , get A component;

[0035] 2. Preparation of component B:

[0036] (1) Add 75.0 grams of polyoxypropylene triol (M=3000) in a dry and clean three-necked flask equipped with a thermometer, a stirring device, and a condenser, and 25.0 grams of polyoxypropylene diol (M=2000) at 110° C. vacuum dehydration for two hours,

[0037] (2) Add 0.6 g of antioxidant 264...

Embodiment 2

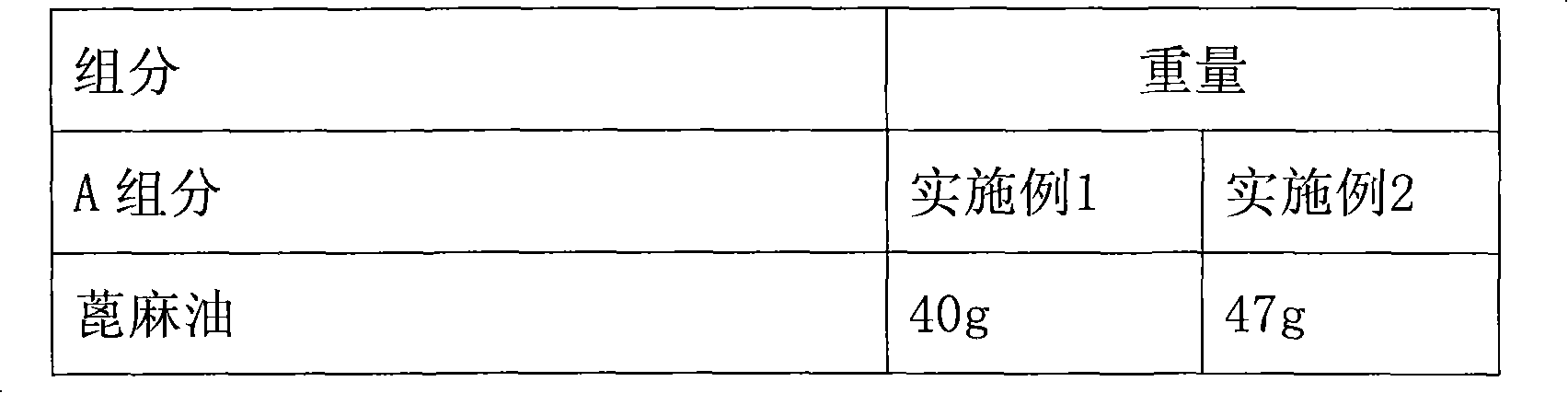

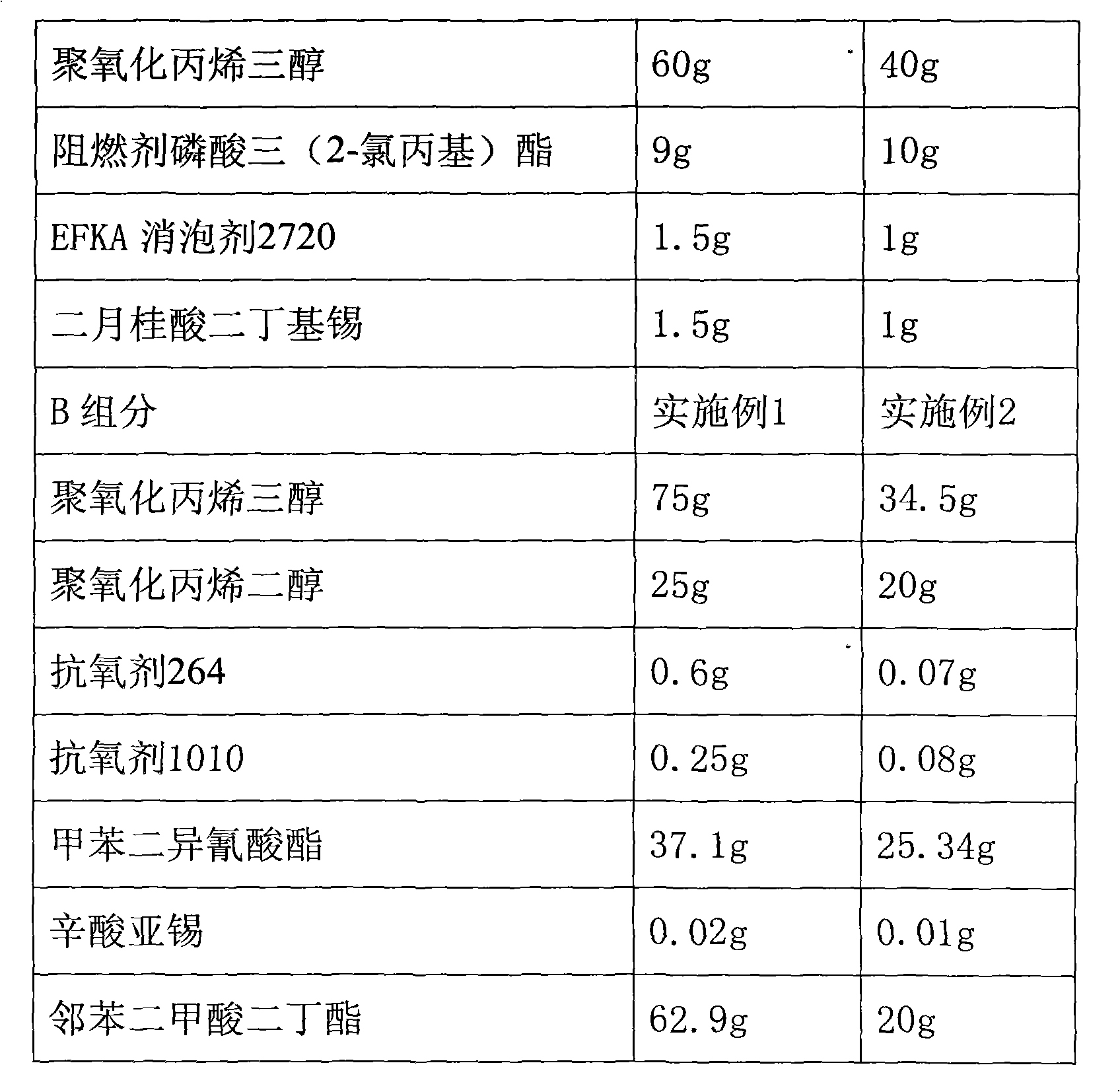

[0041] This embodiment is basically the same as Embodiment 1, and the difference is that the composition and weight of raw materials of component A and component B are different, as shown in the following table.

[0042] The raw material composition of embodiment 1 and embodiment 2

[0043]

[0044]

Embodiment 3

[0046] The steps of the preparation method of this implementation two-component polyurethane potting glue are as follows:

[0047] Preparation of component A: Add 42.00 grams of castor oil and 60.00 grams of polyoxypropylene triol (M=3000) into a dry and clean three-necked flask equipped with a thermometer, a stirring device, and a condenser, and vacuum dehydrate at 110°C for two hours Add 6.00 grams of flame retardant tris(2-chloropropyl) phosphate, 2.00 grams of EFKA defoamer 2720, 2.00 grams of dibutyltin dilaurate, and 1.00 grams of dibutyl phthalate to obtain A components.

[0048] Preparation of component B: Add 200.0 grams of polyoxypropylene triol to a dry and clean three-neck flask equipped with a thermometer, stirring device, and condenser, vacuum dehydrate at 110°C for two hours, and add 0.80 grams of antioxidant when the temperature is lowered to 60°C 264 and 0.70 g of antioxidant 1010. Nitrogen for protection, then add 147.00 g of toluene diisocyanate, add 3.0 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com