Epoxy and PVC composite flexible faced material and preparation method

An epoxy coating, flexible technology, applied in the direction of chemical instruments and methods, floors, layered products, etc., can solve the problem of difficult compounding of epoxy resin and PVC, achieve strong chemical resistance, high efficiency, and increase flexibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

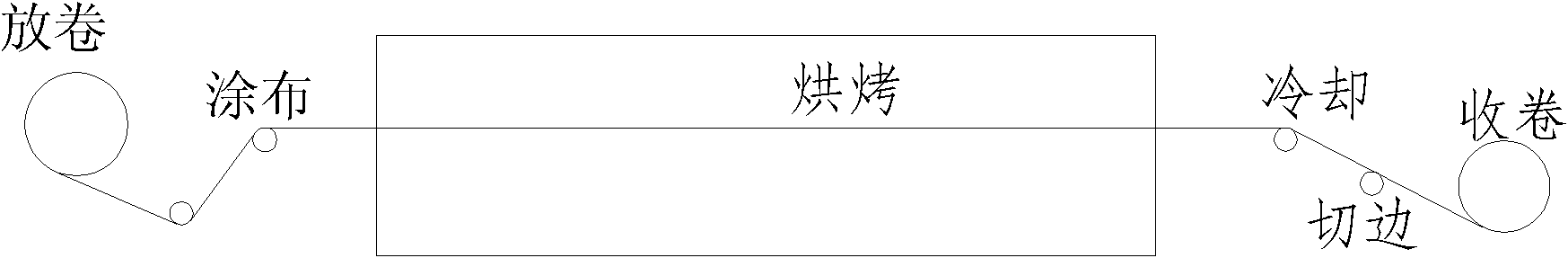

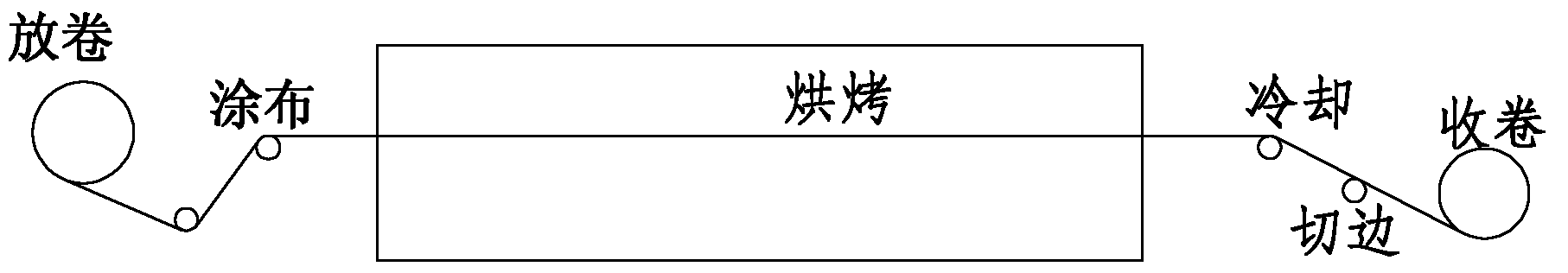

[0034] Such as figure 1 As shown, the preparation method of the epoxy and PVC composite flexible veneer material described in this embodiment, first, prepare two components of epoxy coating respectively, wherein the weight percentage of component A is composed of: 55% epoxy resin E -44, 30% talc, 5% butyl glycidyl ether, 3% carboxy-terminated nitrile rubber, 0.3% polyacrylate copolymer, 0.3% polyorganosiloxane, 2.4% polydimethylsiloxane and 4% color paste. The weight percentage of component B is composed of: 93% polyamide 300 type (amine value 465mgKOH / 100g, viscosity 6-20pa.s / 25°C) and 7% 2,4,6-tris(dimethylaminomethyl )phenol. Mix A component and B component at a weight ratio of 10:3 to prepare an epoxy coating.

[0035] Utilize the coating machine to uniformly coat the epoxy coating on the glass fiber cloth layer of the PVC glass fiber cloth composite coating layer, the thickness of the epoxy coating is generally between 0.1-0.7mm, and then bake at 90°C for 20 Minutes, ...

Embodiment 2

[0037] Such as figure 1 As shown, the preparation method of the epoxy and PVC composite flexible veneer material described in this example first prepares two components of epoxy coating respectively, wherein the weight percentage of component A is composed of: 50% epoxy resin E- 51. 30% talc, 8% butyl glycidyl ether, 5% liquid nitrile rubber, 0.5% polyether modified silicone oil, 0.2% silicone, 1.3% polydimethylsiloxane And 5% color paste. Component B consists of 97% modified alicyclic amine curing agent (amine value 400-600mgKOH / 100g, viscosity 300-600mpa.s / 25°C) and 3% benzyldimethylamine. Mix A component and B component at a weight ratio of 10:2 to prepare an epoxy coating.

[0038] Utilize the coating machine to evenly coat the epoxy coating on the glass fiber cloth layer of the PVC glass fiber cloth composite coating layer. Minutes, and finally cooled, trimmed, and rolled to make a flexible veneer material composited with epoxy and PVC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com