Centering process method for electron beam of plane annular welding line

A technology of annular welds and process methods, which is applied in the field of electron beam centering process of plane annular welds, and can solve the problems of long occupying time, complicated operation process, and large equipment consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

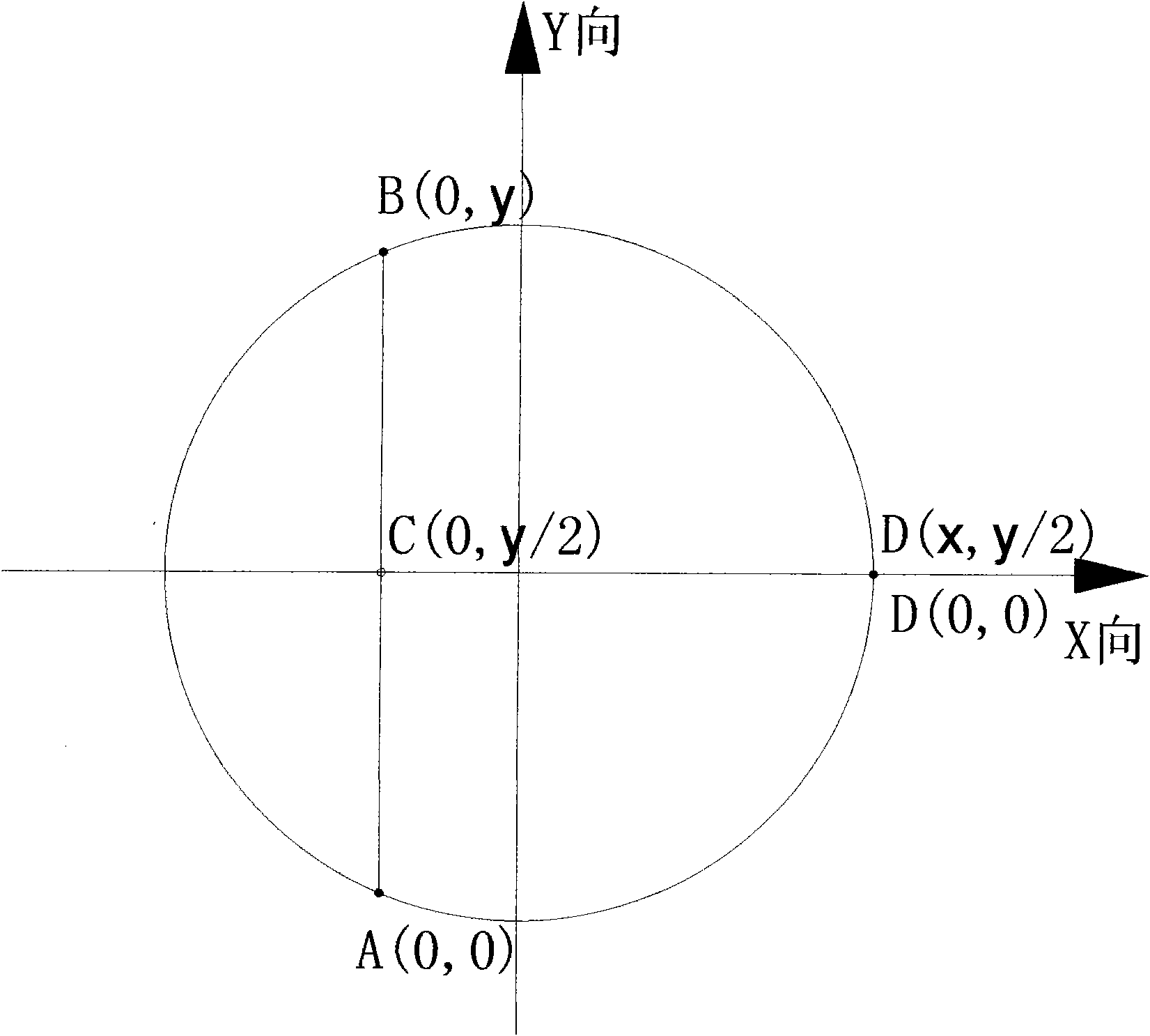

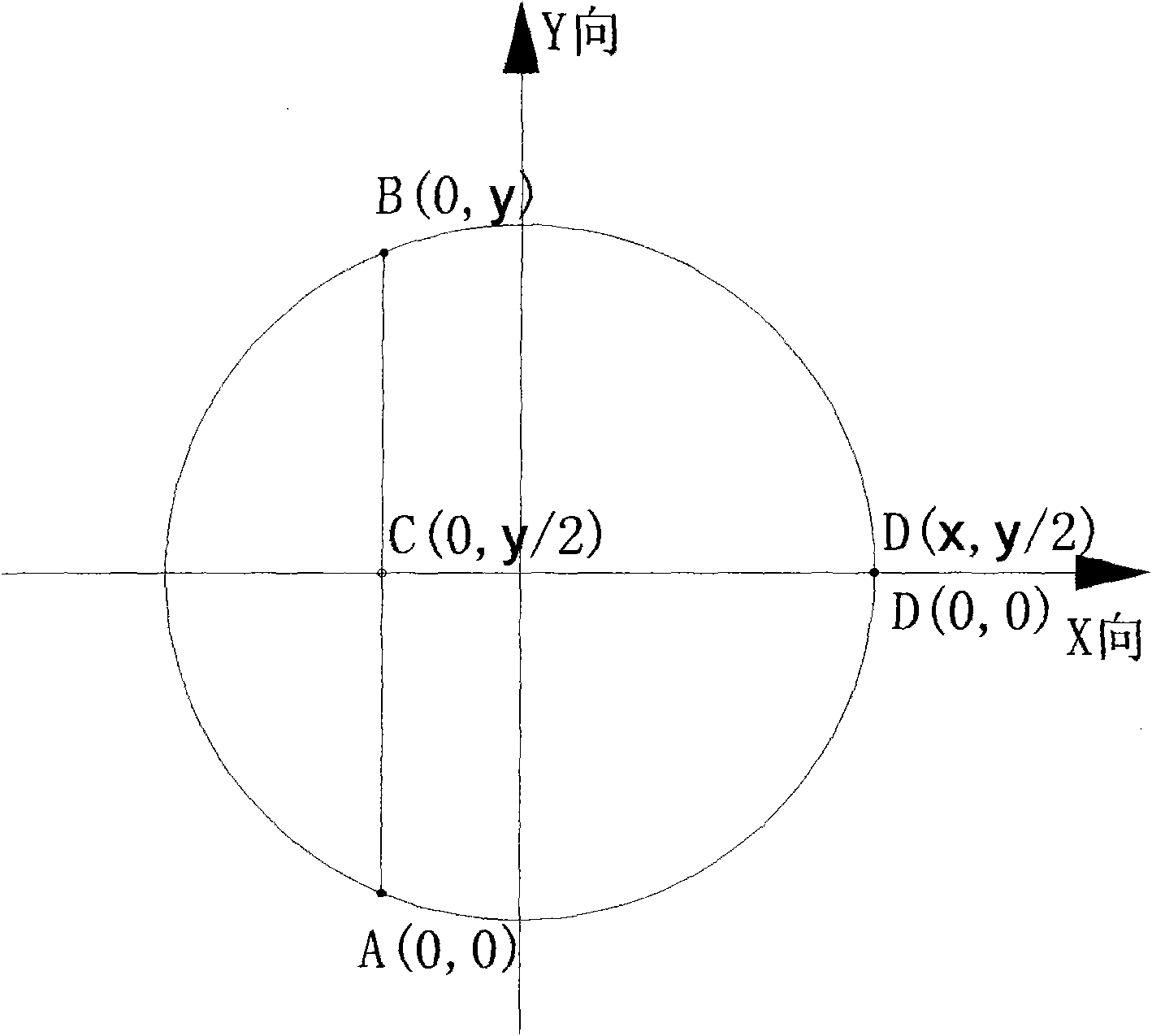

[0030] An electron beam centering process method for a plane circular weld seam: on the basis of the two-axis linkage of the plane coordinate system X-axis and Y-axis, the rapid and accurate centering of the electron beam of the plane circular weld track is realized.

[0031] In the electron beam centering process of the planar annular weld, after determining the track position of the planar annular weld to be welded, use general-purpose electron beam welding equipment, set the electron beam current to 0.1mA, and within 1 to 3 seconds Quickly lower the beam current and determine the position of the electron beam spot relative to the track to be welded.

[0032] The specific operational requirements for seam alignment using general electron beam welding equipment are as follows:

[0033] 1) Calibration: use the target block to confirm the relative position of the electron beam current and the center line of the scale of the general electron beam welding equipment observation sy...

Embodiment 2

[0047] The content of this embodiment is basically the same as that of Embodiment 1, and its difference mainly lies in:

[0048] In the electron beam centering process of the planar annular weld described in this embodiment, in the operation requirements of using general electron beam welding equipment for weld centering, other calibration, pre-positioning, lower beam current, and final welding methods in the prior art are adopted. Specific requirements for positioning and final completion of electron beam welding.

[0049] However, the specific content of the weld seam pair is carried out according to the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com