Papermaking wastewater advanced treatment and recycling device and method thereof

A kind of wastewater treatment, advanced technology, applied in the process of wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment and other directions, can solve the problem of no advanced treatment recycling, wastewater is mostly discharged, waste of water resources, etc. problems, to overcome the unsatisfactory treatment effect, reduce treatment costs, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for purification, regeneration and recycling of 150 tons / day papermaking advanced treatment wastewater.

[0051] The measured indicators of the papermaking advanced treatment wastewater are shown in Table 1.

[0052] Table 1

[0053] serial number

project

unit

measured value

serial number

project

unit

measured value

1

COD Cr

mg / L

186

4

Chroma

80

2

SS

mg / L

90

5

pH

7.5

3

NTU

6

6

μS / cm

5200

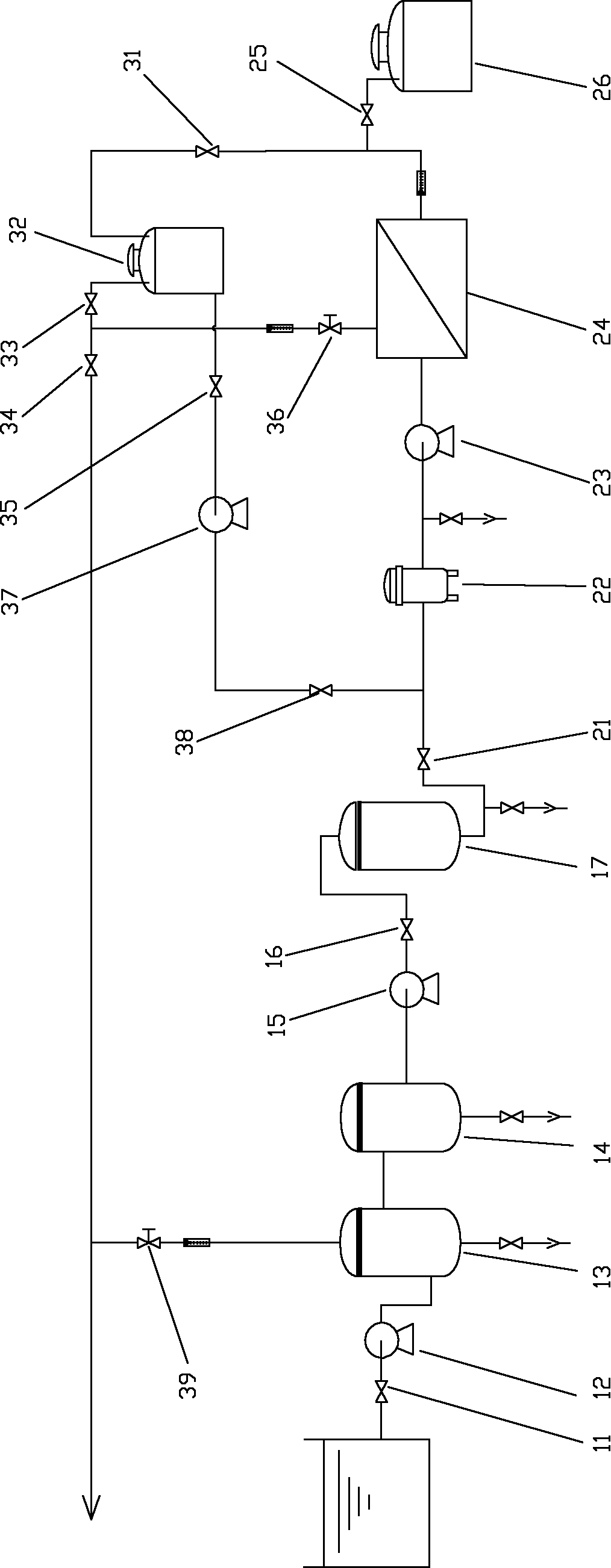

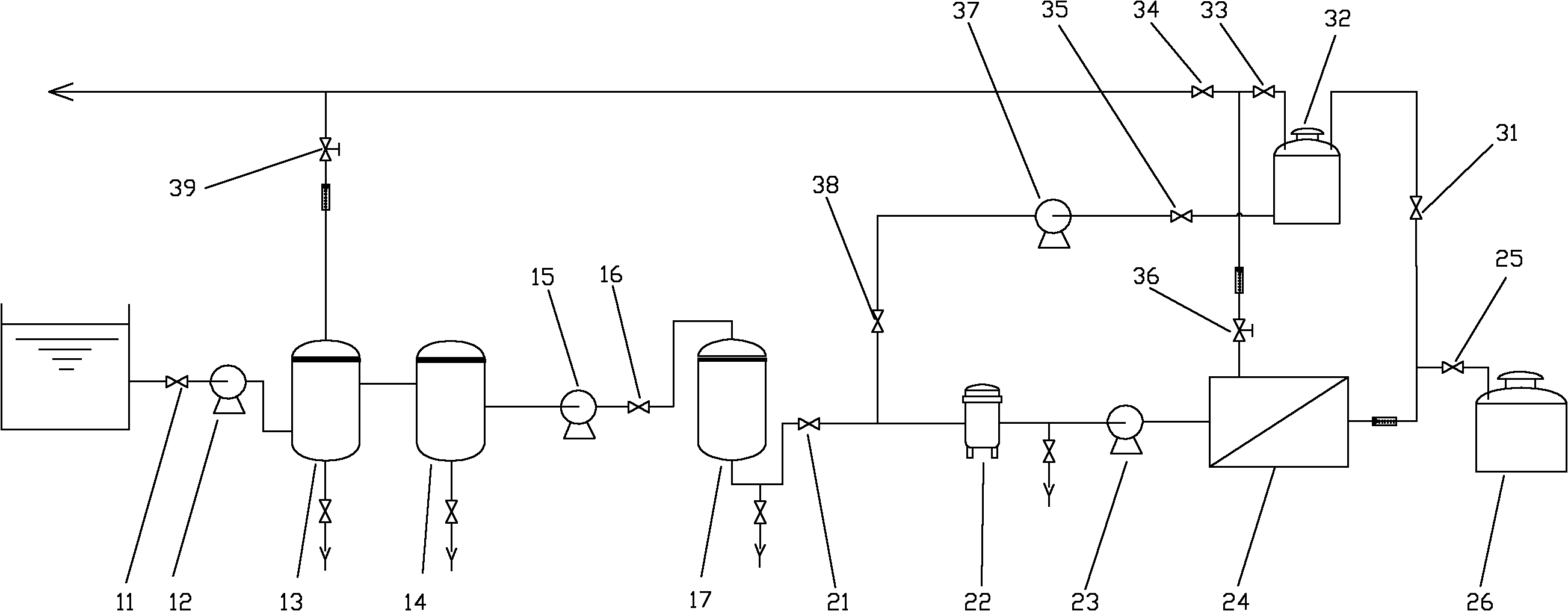

[0054] The advanced papermaking waste water is input into the nano-catalyzed electrolytic tank 13 through the water pump 12 at a flow rate of 7.5T / h through the water pipe. When the system runs smoothly, it enters the buffer tank 14, and enters the filter tank 17 through the water pump 15 and valve 16 for filtration to remove the impurities in the water. Solid impurities, plankton, bacteria, ...

Embodiment 2

[0063] Purification and recycling method of 3000 tons / day papermaking advanced treatment wastewater.

[0064] Described papermaking advanced treatment waste water is measured, and index is as shown in table 4:

[0065] Table 4

[0066] serial number

project

unit

measured value

serial number

project

unit

measured value

1

COD Cr

mg / L

109

4

Chroma

120

2

SS

mg / L

75

5

pH

7.5

3

NTU

6

6

μS / cm

3200

[0067]The advanced papermaking waste water is input into the nano-catalytic electrolytic tank 13 through the water pump 12 at a flow rate of 150T / h. When the system is running smoothly, the wastewater electrolyzed by the nano-catalytic electrolytic tank 13 enters the buffer tank 14, passes through the water pump 15 and the valve 16, and enters the The multimedia filter tank 17 filters and removes solid im...

Embodiment 3

[0076] Purification and recycling method of 6000 tons / day papermaking advanced treatment wastewater.

[0077] The papermaking advanced treatment wastewater has been measured, and the indicators are as shown in Table 7:

[0078] Table 7

[0079] serial number

project

unit

measured value

serial number

project

unit

measured value

1

COD Cr

mg / L

234

4

Chroma

110

2

SS

mg / L

73

5

pH

7.5

3

NTU

6

6

μS / cm

3700

[0080] Wastewater from papermaking advanced treatment is input into the nano-catalyzed electrolytic tank 13 through the water pump 12 at a flow rate of 300T / h. The microfiltration filter tank 17 filters and removes solid impurities, plankton, bacteria and colloids in the water to obtain purified waste water.

[0081] The working voltage of nano-catalytic electrolysis is 98-100V, the current inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Turbidity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com