Liquor high-efficient flavor intensifier and application of flavor intensifier in production of white liquor or liquor making with uncooked materials

A flavor enhancer and high-efficiency technology, applied in the field of liquor, can solve the problems of no mention of the content of ethyl acetate in the main ester of yeast and complex enzymes, difficulty in increasing the content of flavor components, and backward technology, and achieve a significant effect of flavor enhancement. Highly effective and versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

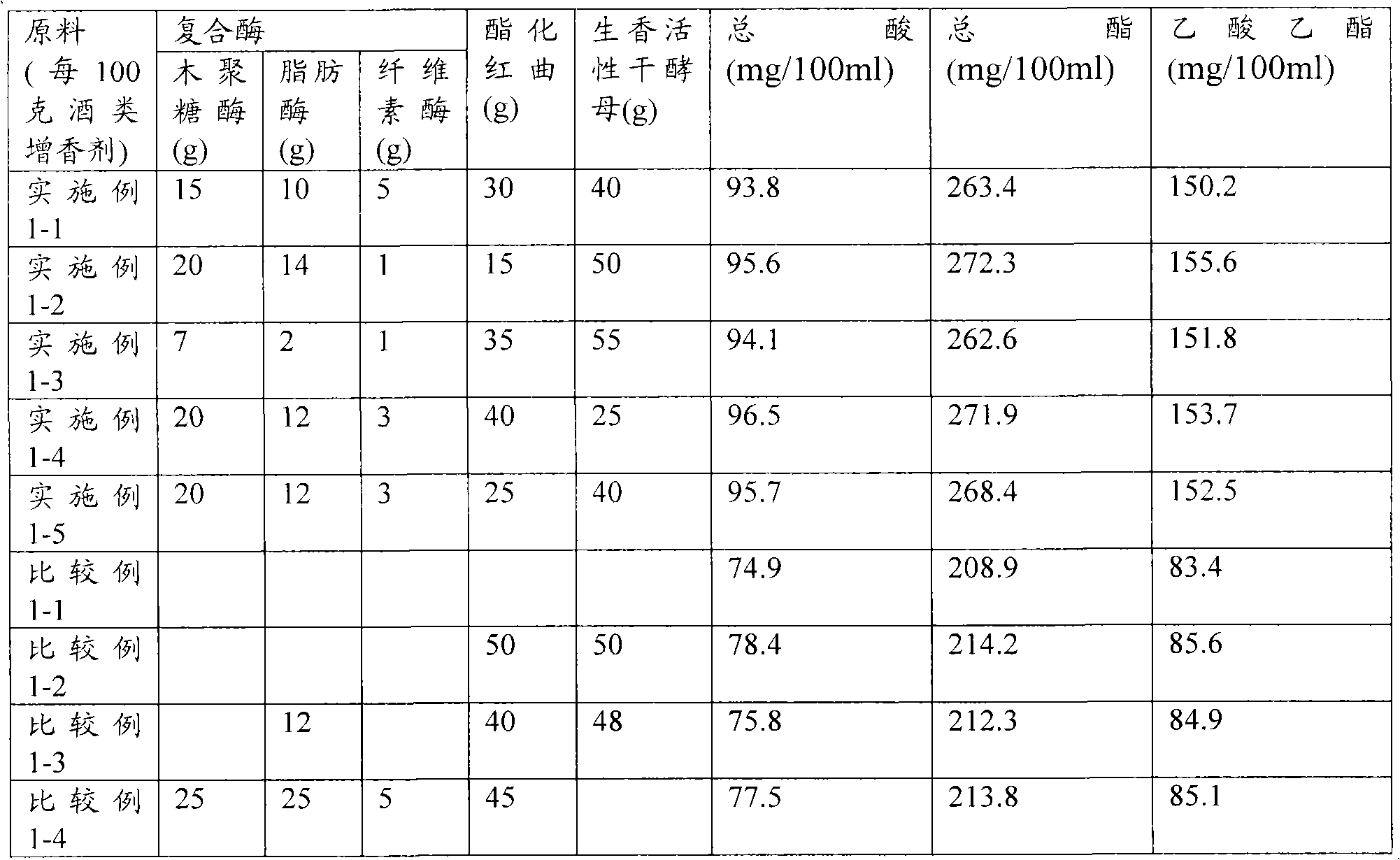

[0042] Example 1-1: The process, use method and effect of the high-efficiency flavor enhancer for alcoholic beverages of the present invention used in the solid-state brewing process of corn distilled wine:

[0043] The process steps are: soaking grain→initial steaming→re-steaming→making koji→fermenting→distilling

[0044]After the raw materials for producing corn distilled wine go through the steps of soaking grain→initial steaming→re-steaming, in the step of koji adding 0.3% of the raw grain weight of the high-efficiency flavor enhancer for alcoholic beverages of the present invention. In the flavoring agent of Example 1-1, every 100 grams of the flavoring agent product contains 15 grams of xylanase, 10 grams of lipase, 5 grams of cellulase, 30 grams of esterified red yeast rice, aroma-producing active dry Yeast 40 grams. Finally, the product temperature was reduced to about 30° C., and the finished wine (57% v / v) was squeezed, and the detection indicators were shown in Tab...

Embodiment 1-2

[0046] Corn distilled wine was produced in the same manner as in Example 1-1, except that in the koji step, 0.3% of the weight of the raw grain was added to the high-efficiency flavor enhancer for wine of the present invention. In the flavoring agent of Example 1-2, every 100 grams of the flavoring agent product contains 20 grams of xylanase, 14 grams of lipase, 1 gram of cellulase, 15 grams of esterified red yeast rice, aroma-producing active dry Yeast 50 grams. Finally, the product temperature was reduced to about 30° C., and the finished wine (57% v / v) was squeezed, and the detection indicators were shown in Table 1 below.

Embodiment 1-3

[0048] Corn distilled wine was produced in the same manner as in Example 1-1, except that in the koji step, 0.3% of the weight of the raw grain was added to the high-efficiency flavor enhancer for wine of the present invention. In the flavor enhancer of Examples 1-3, every 100 g of flavor enhancer products contains 7 grams of xylanase, 2 grams of lipase, 1 gram of cellulase, 35 grams of esterified red yeast rice, and aroma-producing active dry Yeast 55 grams. Finally, the product temperature was reduced to about 30° C., and the finished wine (57% v / v) was squeezed, and the detection indicators were shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com