Technology for medium-frequency induction furnace to smelt ZL424 and aluminum casting alloy

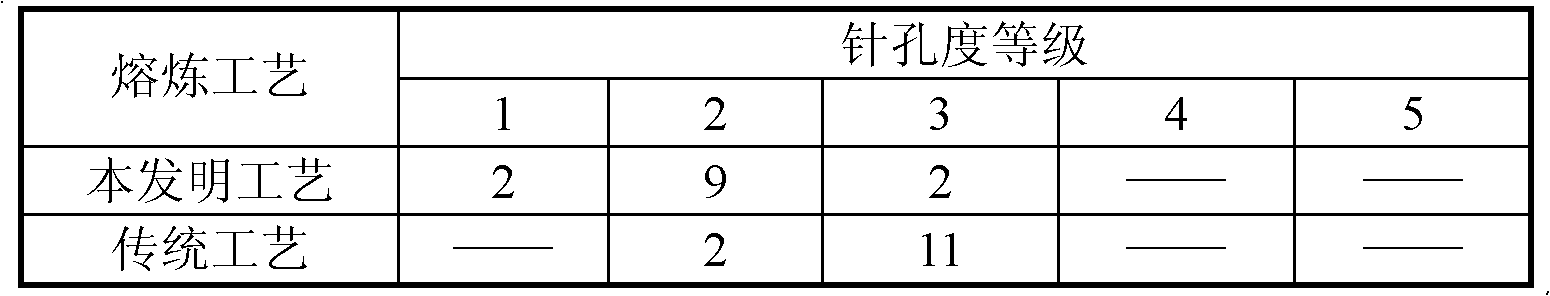

A technology for casting aluminum alloy, ZL424, applied in the field of casting production process, can solve the problems of unreasonable refining process, easy generation of pores and inclusions in castings, and unclean degassing and slag removal of alloys, so as to improve mechanical properties and reduce metal burning loss. , the effect of improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0036] A process for smelting ZL424 cast aluminum alloy in an intermediate frequency induction furnace, the smelting steps are:

[0037] (1) Start-up of the intermediate frequency induction furnace:

[0038] ①. Check the water circuit before starting up:

[0039] Before use, check whether the electrical circuit is in good condition, whether the components are damaged, and whether the contact points are loose and disconnected. If the above situation occurs, it should be used after eliminating the fault.

[0040] Check the waterway, water temperature, and water quality to meet the requirements of the device. The inlet water temperature is +5°C to +40°C, and the inlet water pressure is 1.0kg / cm2 to 2.0kg / cm2. Check whether the joints of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com