Novel-structure wear-resistant bit tooth

A new type of structure, technology of wear-resistant body, applied in the direction of earthwork drilling, slitting machinery, etc., can solve the problems of no impact toughness, broken carbide sleeve, non-abrasion resistance, etc., and achieve high-strength wear resistance, The effect of improving work efficiency and reducing coal mining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

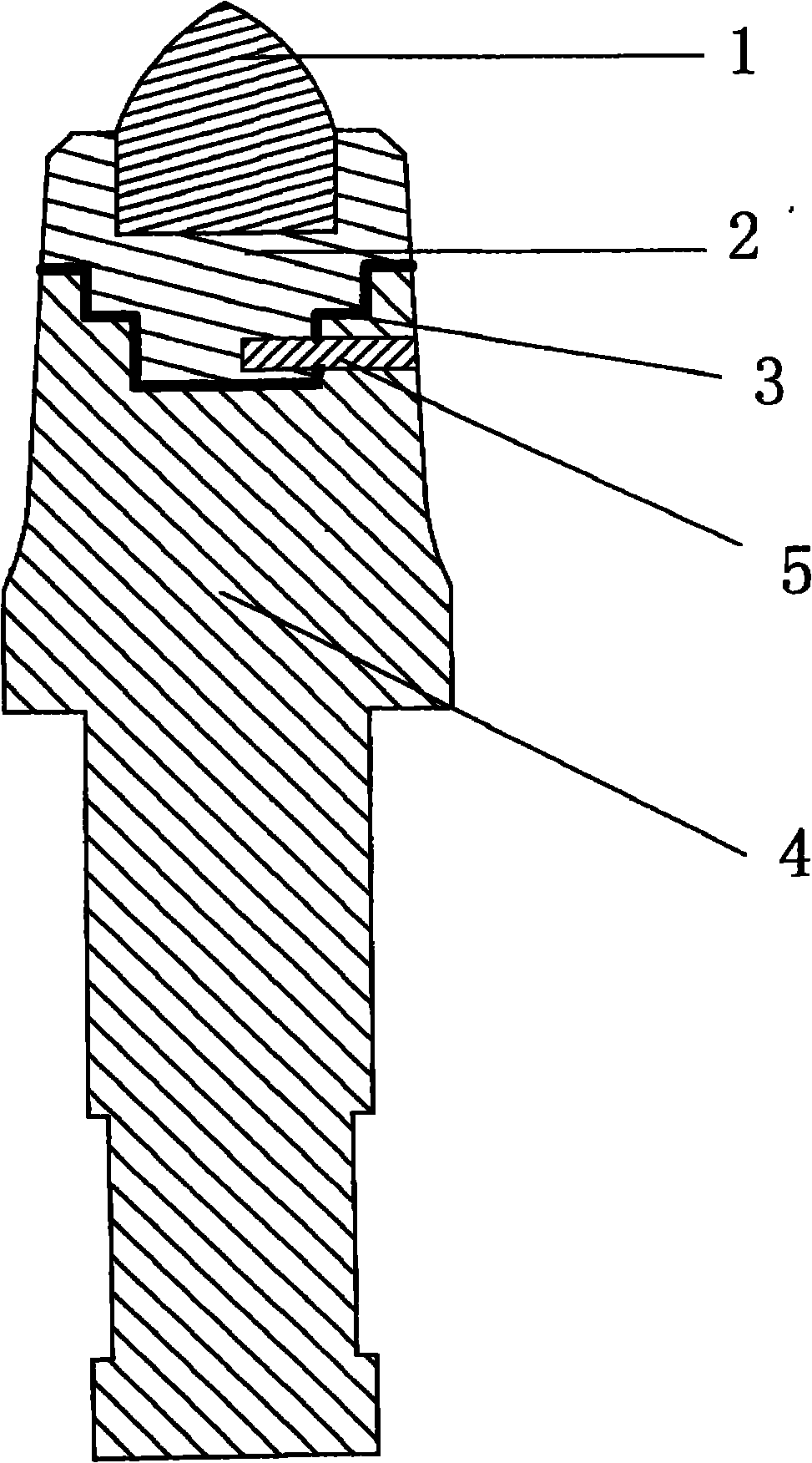

[0015] Such as figure 1 A novel structure wear-resistant pick body is shown, the pick tooth body (4) and wear-resistant body (2) of alloy structural steel are machined, the pick tooth body (4) and wear-resistant body ( 2) Annealing treatment is carried out after the brazing filler metal (3) is welded, and then the joint part (5) of the pick tooth body (4) and the wear-resistant body (2) of the alloy structural steel is punched and pinned for locking or punching The hole tapping is screwed into the bolt for locking, and the cemented carbide column teeth (1) are welded on the wear-resistant body (2) by silver and copper brazing methods, and other heat treatment methods remain unchanged.

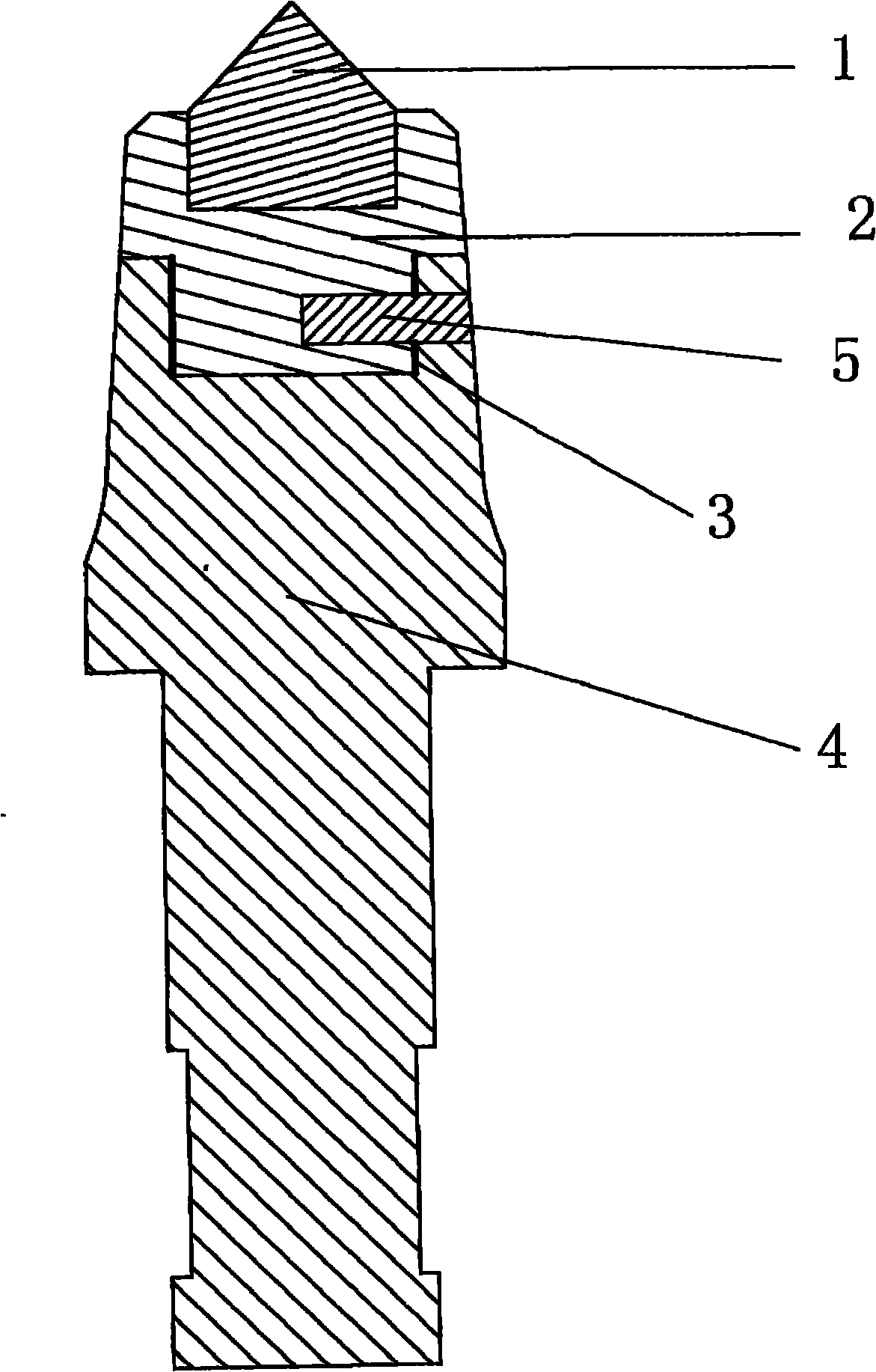

[0016] Such as figure 2 A new type of wear-resistant pick body is shown, the pick tooth body (4) of alloy structural steel and the wear-resistant body (2) are machined, and the upper end of the pick tooth body (4) of alloy structural steel is processed with threads (3), the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com