Electric heating floor board

A floor and electric heating technology, which is applied in the field of building decoration materials, can solve problems such as the floor is prone to moisture, complicated installation, and difficult maintenance, and achieves the effects of saving costs, reducing construction difficulty, and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

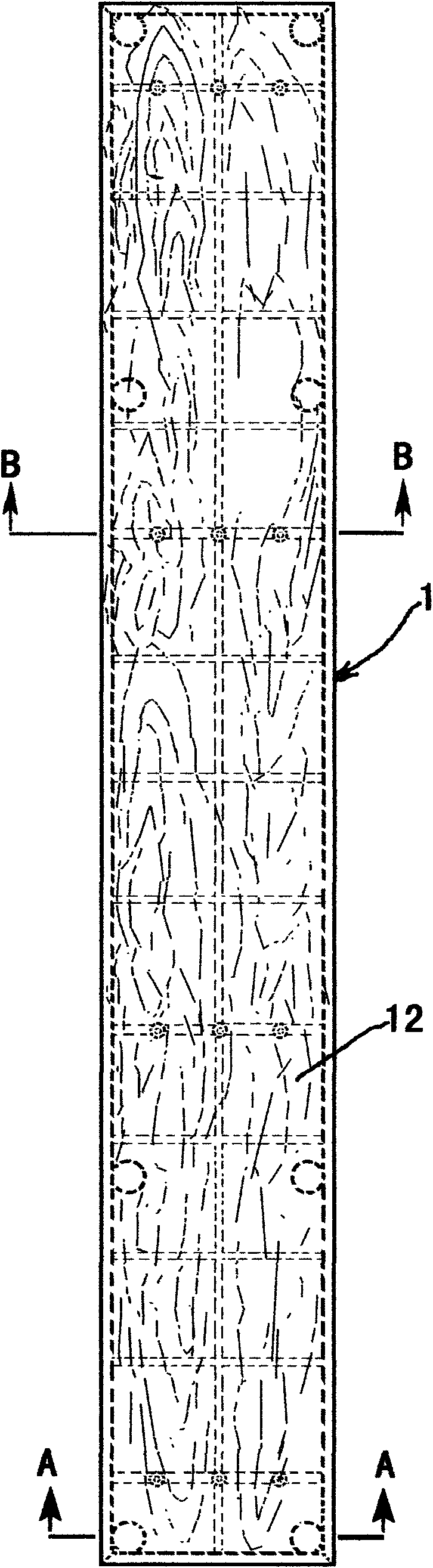

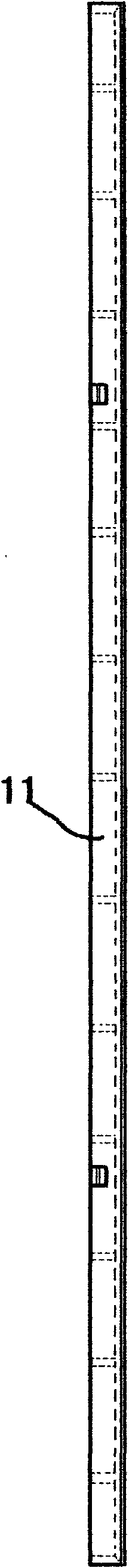

[0050] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the electric heating geothermal floor 1 of the present invention includes a base plate 11 and a panel 12 disposed on the base plate 11 , and the upper surface of the panel 12 is printed or pasted with various decorative boards or veneers with patterns.

Embodiment 2

[0051] Embodiment 2: as Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, the two longitudinal sides of the bottom plate 11 are provided with common connection grooves 14, and the two transverse sides are provided with electrode connection grooves 13. On the lower surface of the bottom plate, cylinders 15 are arranged on the surface of the bottom plate 11, and the cylinders 15 are arranged in a certain order. In this embodiment, there are four rows of cylinders 15, and each row has three cylinders 15. The cylinder 15 is arranged perpendicular to the bottom surface of the bottom plate and integral with the bottom plate. The center of the cylinder 15 is provided with a central through hole 18 for screws to pass through. The diameter of the through hole at the end of the central through hole 18 facing the bottom surface of the bottom plate is larger than the diameter of the through hole at the end of the central through hole 18 facing the panel...

Embodiment 3

[0052] Embodiment 3: as Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 19 As shown, the electric heating geothermal floor of the present invention includes a bottom plate 11 and a panel 12 arranged on the bottom plate 11, the shown panel 12 includes a base plate 122 and at least one decorative surface plate 121, and is arranged on the base plate 122 and the decorative surface plate 121 Between the electric heating element 21, the upper surface of the substrate is pre-embedded with a number of connection nuts 23 used to connect with the bottom plate 11 and is provided with corresponding plugs or accessories 22 connected with the two electrodes of the electric heating element. The four sides of the bottom plate are composed of upper convex strips 19 and lower convex strips 20 and form an overall rectangular concave container structure with the bottom surface 4 of the bottom plate 11 . The upper surface of the upper protruding strip 19 is formed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com