Resin composition for coating material of electrical cables and electrical cables using the same

A technology of resin composition and coating material, applied in plastic/resin/wax insulators, coatings, insulated cables, etc., can solve the problems of reduced tensile strength of polymeric materials, reduced cable flexibility, low flame retardancy, etc. Achieves excellent tensile strength and flame retardancy, eliminates need for braid, reduces outer diameter and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 and comparative example 1-3

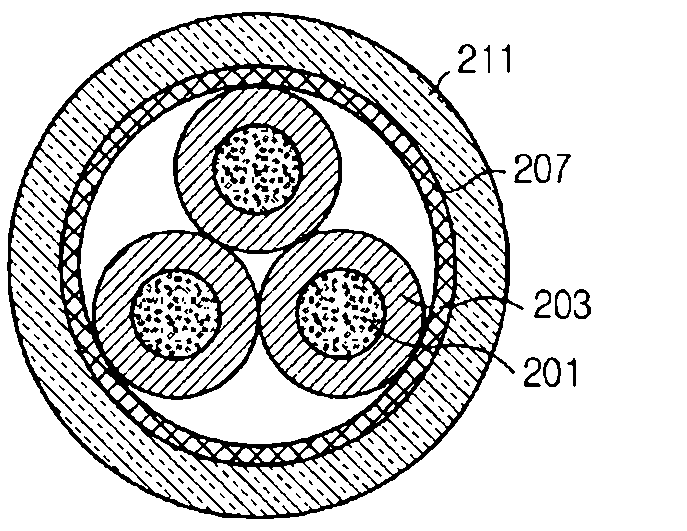

[0036] Samples for determining material properties were fabricated by mixing-milling the components in Table 1 with an open roll at about 130°C and forming with pressure at 170°C for 5 minutes. And, a cable comprising a conductor 201, an insulating layer 203, an embedding layer 207 and a sheath 211 was manufactured using the composition prepared according to the components and contents of Table 1, and made to have the following image 3 the shape shown. The manufactured samples were tested for their mechanical properties at normal temperature, mechanical properties after heating, oxygen index and weight loss after heating, and the freezing resistance, flame retardancy and tensile properties of the cables were evaluated.

[0037] [Table 1]

[0038]

[0039] In Table 1, "resin a" is PVC having a degree of polymerization of 800 or more, "resin b" is chlorinated PCV, and "resin c" is PVC having a degree of polymerization of less than 800. And, "plasticizer a" is DINP, "plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com