Electrochemical polymerization solution and electrochemical polymerization process for preparing solid electrolyte layer on capacitor

A technology of solid electrolyte layer and polymerization process, applied in the field of electrochemical polymerization solution and process, can solve the problems of high control cost and general performance in solid electrolytic capacitors, and achieve the effects of reduced control cost, low toxicity and common materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

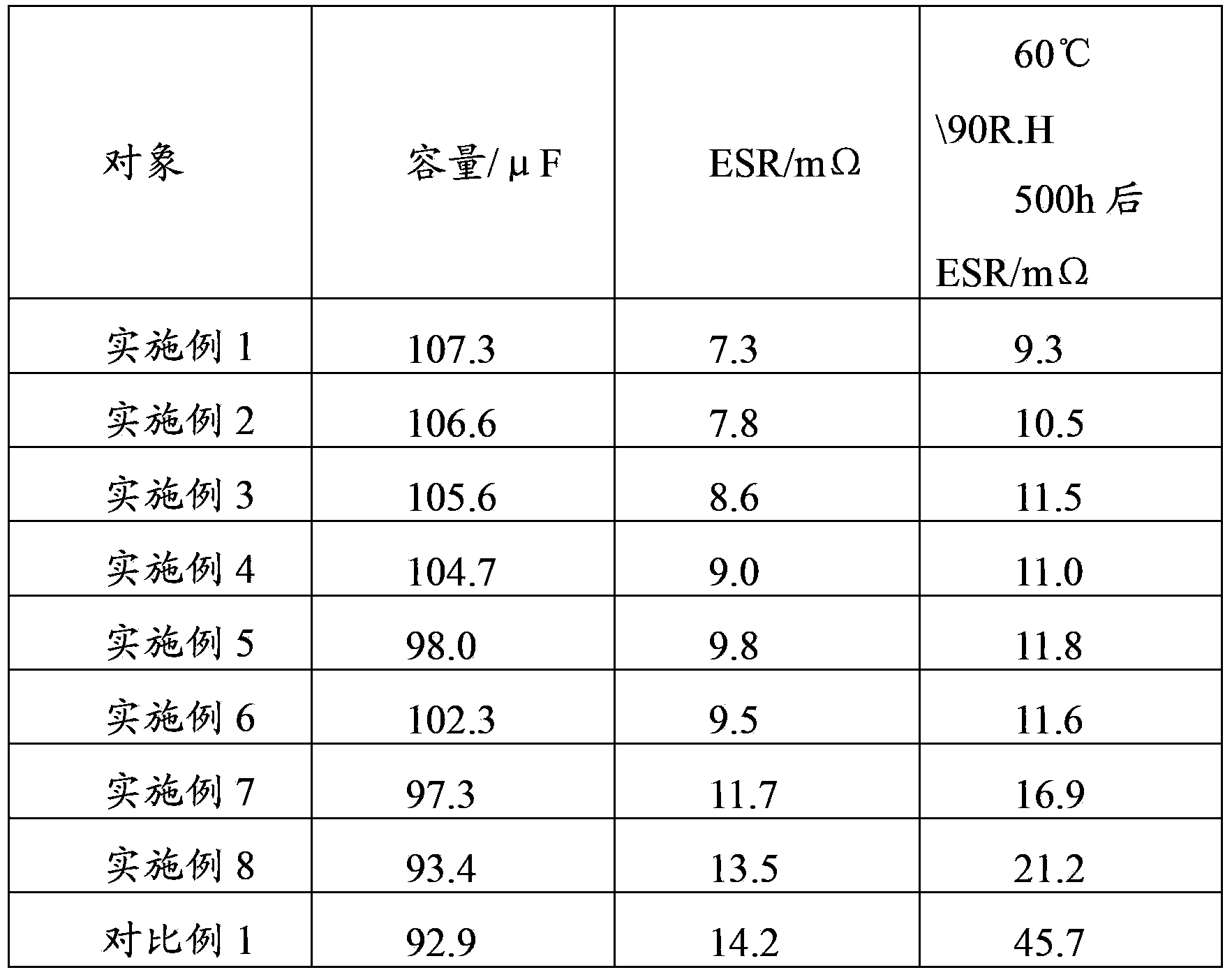

Examples

Embodiment 1

[0011] The first solid electrolyte layer polypyrrole is prepared by chemical polymerization of a 13VF aluminum foil containing alumina (effective area 3.5mm × 4.0mm), and then an electrochemical polymerization process is performed. Specifically, the aluminum foil containing the first solid electrolyte layer polypyrrole is mixed with The external electrode is connected as the anode, with 2cm 2 The carbon conductive electrode was the cathode, and galvanostatic polymerization was carried out at 10°C in an aqueous solution containing 0.4M Py (pyrrole monomer) and 0.3M p-toluenesulfonate. The continuous time of the solution is controlled within 24 hours, and the polymerization electricity is 0.5C (coulomb). Then washing and drying, the second solid electrolyte layer polypyrrole is obtained. After the electrochemical polymerization process is completed, a carbon-containing cathode layer and a silver-containing cathode layer are sequentially formed on the outer surface of the second...

Embodiment 2

[0013] Different from Example 1, with 10cm 2 The carbon conductive electrode is used as the cathode, which is electrochemically polymerized in an ethanol solution at 0 °C with a polymerization charge of 1.0 C, and the continuous use of the solution is controlled within 96 hours.

Embodiment 3

[0015] Different from Example 1, with 1cm 2 The titanium conductive electrode is used as the cathode, which is electrochemically polymerized in a mixed solution of butanol and pure water at 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com