Method for comprehensively utilizing rice bran

A technology of rice bran and defatted rice bran, which is applied to the preparation method of peptides, chemical instruments and methods, applications, etc., can solve the problems of affecting the physiological activity of products, large differences in molecular weight distribution, and high salt content in finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

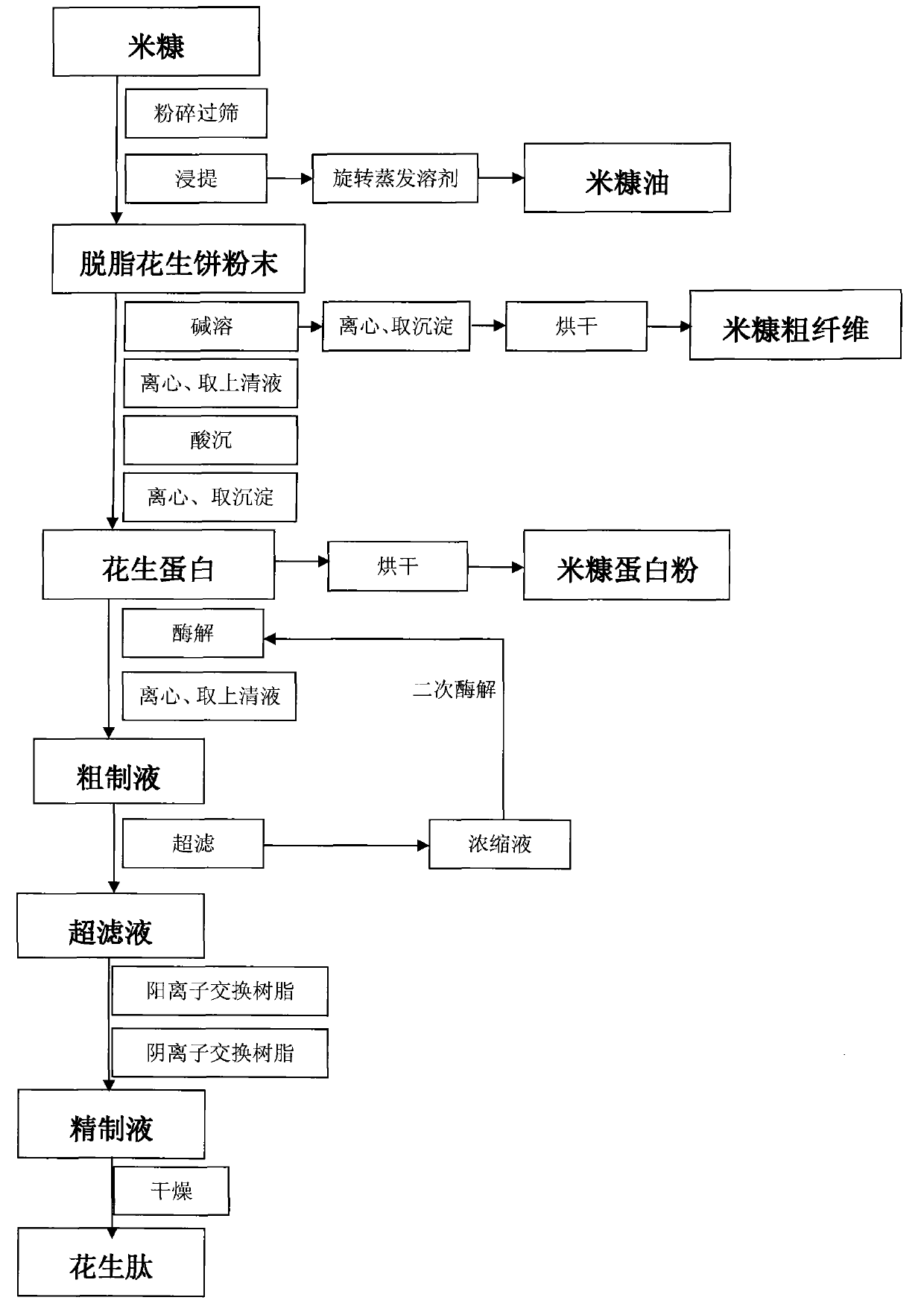

Method used

Image

Examples

Embodiment 1

[0035] A method for comprehensively utilizing rice bran, the method comprising the steps of:

[0036] (1) Weigh 100g of rice bran, crush it through a 60-mesh sieve, use Soxhlet extraction method, use 95% n-hexane solvent to extract at 50°C for 2 hours, then filter the n-hexane solution, and dry the rice bran until the n-hexane is completely Volatility is defatted rice bran; the filtrate is completely evaporated with n-hexane with a rotary evaporator, and the rest is rice bran oil, weighing 11.3g;

[0037] (2) Pour the defatted rice bran in step (1) into 600mL water, heat to 45°C, adjust the pH to 9.0 with NaOH reagent, stir continuously for 15min, centrifuge at 3000r / min for 15min, and take the supernatant; Precipitated and dried, it was rice bran crude fiber, weighing 53.2g;

[0038] (3) Heat the supernatant of step (2) to 80°C, adjust the pH to 3.5 with citric acid reagent, stir continuously for 10 minutes, 3000r / min, 15 minutes, centrifuge to collect the precipitate, which...

Embodiment 2

[0048] A method for comprehensively utilizing rice bran, the method comprising the steps of:

[0049] (1) Weigh 500g of rice bran, crush it through a 60-mesh sieve, use Soxhlet extraction method, extract it with 95% n-hexane solvent at 50°C for 2 hours, then filter the n-hexane solution, and air-dry the rice bran until the n-hexane is completely Volatility is defatted rice bran; the filtrate is completely evaporated with n-hexane with a rotary evaporator, and the rest is rice bran oil, weighing 58.9g;

[0050] (2) Pour the defatted rice bran in step (1) into 2.5L of water, heat to 50°C, adjust the pH to 8.5 with NaOH reagent, stir continuously for 15min, centrifuge at 3000r / min for 15min, and take the supernatant; The precipitate was dried, and it was rice bran crude fiber, weighing 247.3g;

[0051] (3) Heat the supernatant of step (2) to 90°C, adjust the pH to 3.0 with citric acid reagent, stir continuously for 10 minutes, 3000r / min, 15 minutes, centrifuge to collect the pre...

Embodiment 3

[0061] A method for comprehensively utilizing rice bran, the method comprising the steps of:

[0062] (1) Weigh 1000g of rice bran, crush it through a 80-mesh sieve, use Soxhlet extraction method, use 95% n-hexane solvent to extract at 50°C for 2 hours, then filter the n-hexane solution, and dry the rice bran until the n-hexane is completely Volatility is defatted rice bran; the filtrate is completely evaporated with n-hexane with a rotary evaporator, and the rest is rice bran oil, weighing 110.2g;

[0063] (2) Pour the defatted rice bran in step (1) into 7L water, heat to 45°C, adjust the pH to 9.0 with NaOH reagent, stir continuously for 15min, centrifuge for 15min at a speed of 3000r / min, and take the supernatant; Precipitated and dried, it was rice bran crude fiber, weighing 537.6g;

[0064] (3) Heat the supernatant of step (2) to 90°C, adjust the pH to 3.0 with citric acid reagent, stir continuously for 10 minutes, 3000r / min, 15 minutes, centrifuge to collect the precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com