Microalgae screening method and system thereof

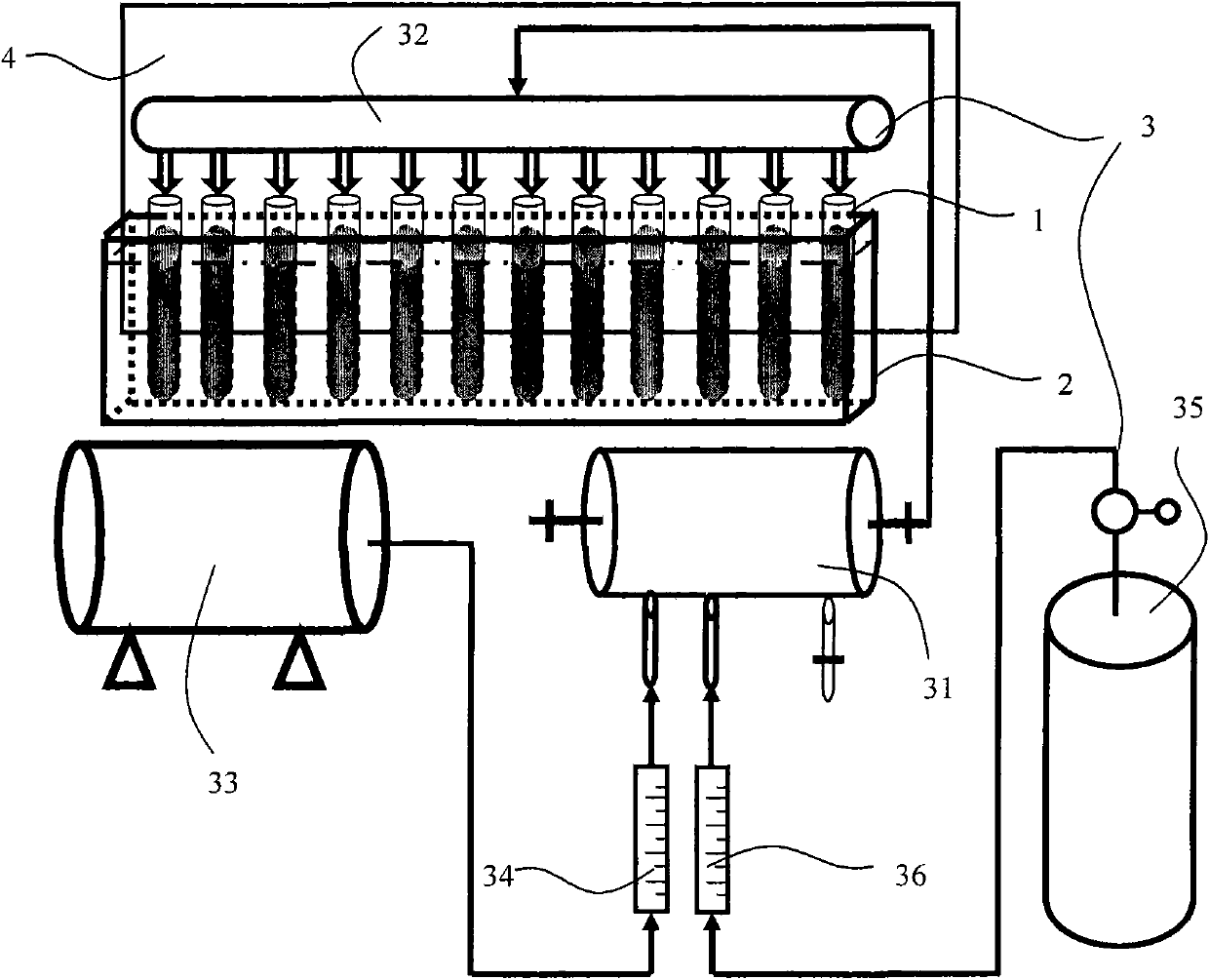

A technology of microalgae and microalgae, which is applied in the biological field to achieve the effect of improving speed and efficiency, stable and consistent cultivation temperature and ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

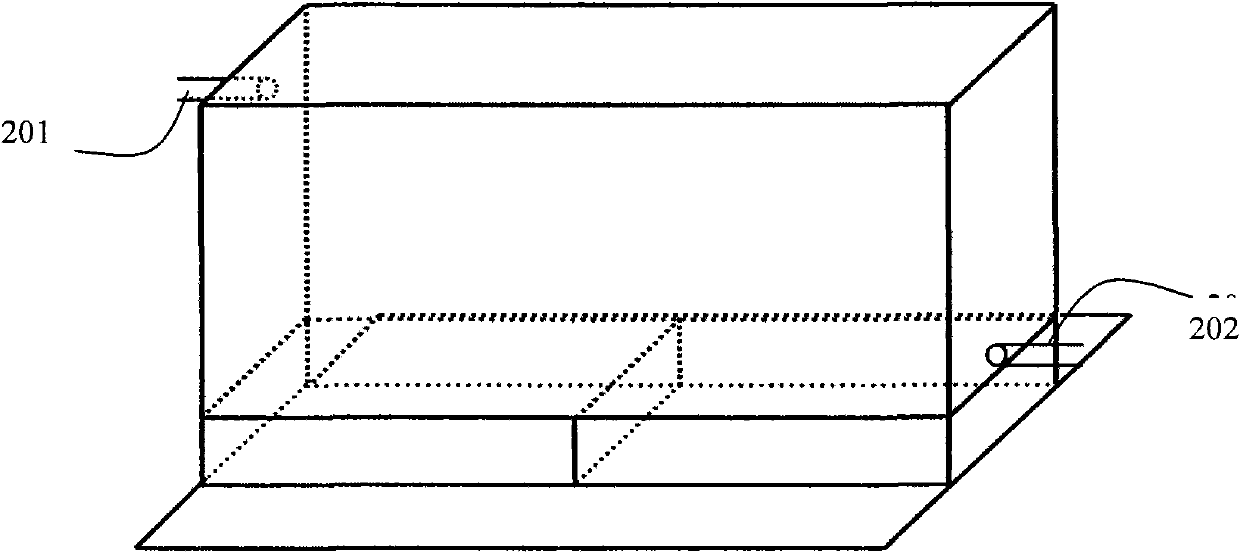

[0085] The microalgae screening method provided in the first embodiment of the present invention explores the best growth (cultivation) conditions for the same type of microalgae strains, and its process is as follows Figure 9 As shown, the execution steps are as follows:

[0086] Step S101: Cultivate the same type of microalgae strains in the microalgae culture solution contained in several photobioreactors in the microalgae cultivation device.

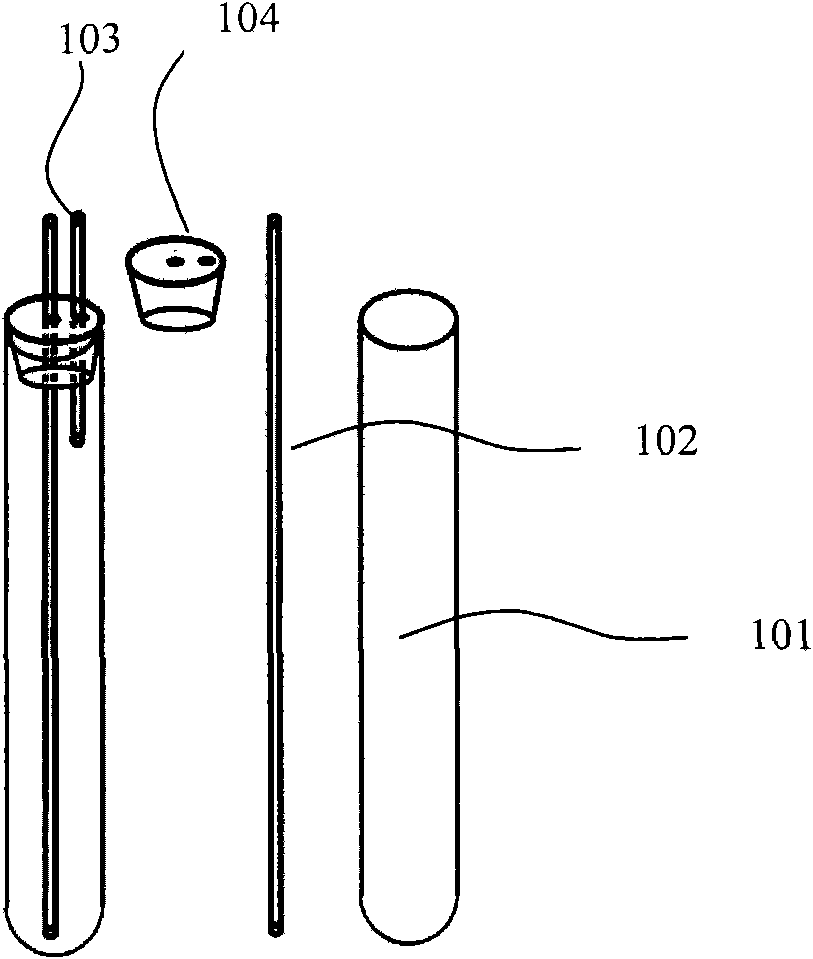

[0087] For example: the diameter of the selected glass column reactor is 40mm, the height is 600mm, the volume of the whole reactor is 750ml, and the reactor is made of borosilicate glass material. Each photobioreactor of the microalgae cultivation device holds microalgae strains of the same algae species.

[0088] Step S102: The microalgae cultivation device provides different cultivation conditions for the microalgae strains in each photobioreactor.

[0089] That is, for the microalgae strains in each photobioreactor, the photos...

Embodiment 2

[0104] The microalgae screening method provided in Example 2 of the present invention provides stable and consistent culture conditions for different types of microalgae strains, and explores which algae species has the best biological performance under specific growth (cultivation) conditions. The process is as follows Figure 10 As shown, the execution steps are as follows:

[0105] Step S201: Cultivate several different types of microalgae strains in the microalgae culture solution contained in several photobioreactors in the microalgae cultivation device.

[0106] For example: the selected glass column reactor 101 has a diameter of 40 mm, a height of 600 mm, and a volume of the entire reactor of 750 ml, and the reactor is made of borosilicate glass. Each photobioreactor of the microalgae cultivation device holds microalgae strains of different algae species. For example: Chlorococcum sp. and Chlorella vulgaris are microalgae strains of two different algae species, the med...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com