Process for production of 13C

A manufacturing method and reaction technology, which are applied in the preparation/purification of carbon, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as not reaching the industrialized level, and achieve easy reaction control, The effect of simple reaction device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

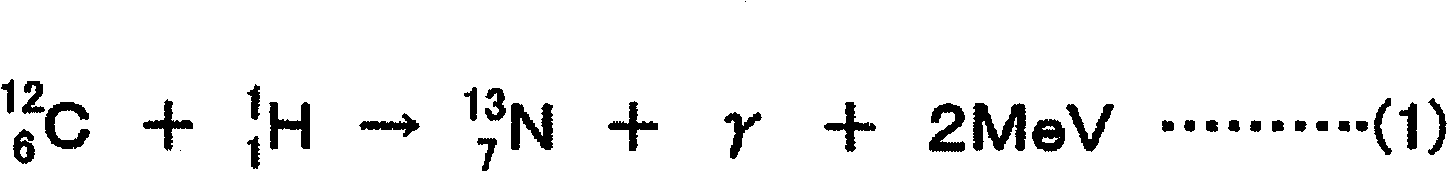

Problems solved by technology

Method used

Image

Examples

Embodiment 1

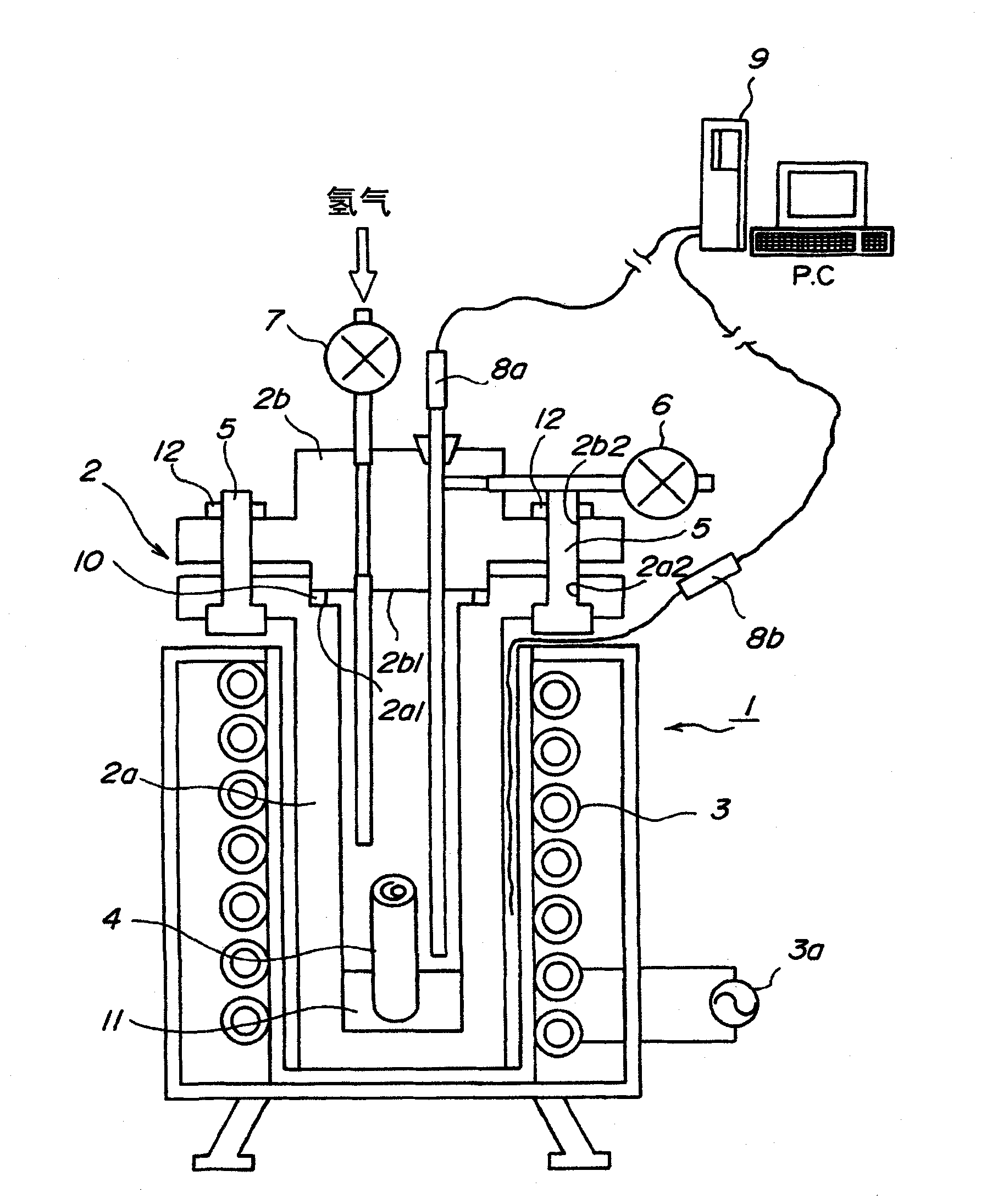

[0041] figure 1 In the shown reactor 1, a cylindrical autoclave 2 made of SUS with an outer diameter of 56 mm, an inner diameter of 26 mm, and an inner volume of 88 cc is installed in an electric heater 3 connected to a power supply 3 a, and the main body of the autoclave is heated. In 2a, 1 cc of creosote oil (sulfur content rate: 0.07% by weight) containing a sulfur compound using carbon compound 11 as a raw material and a 100% pure nickel sintered body with a porosity (area ratio) of 5% is inserted, and the The metal gasket 10 fits the convex part 2b1 of the autoclave cover 2b into the concave part 2a1 of the autoclave main body 2a, and penetrates to six places provided on the respective peripheral parts of the autoclave main body 2a and the autoclave cover 2b. Six bolts 5 are inserted through the holes 2a2 and 2b2, and fastening nuts 12 are screwed to the bolts 5 to fix the autoclave lid 2b to the autoclave main body 2a.

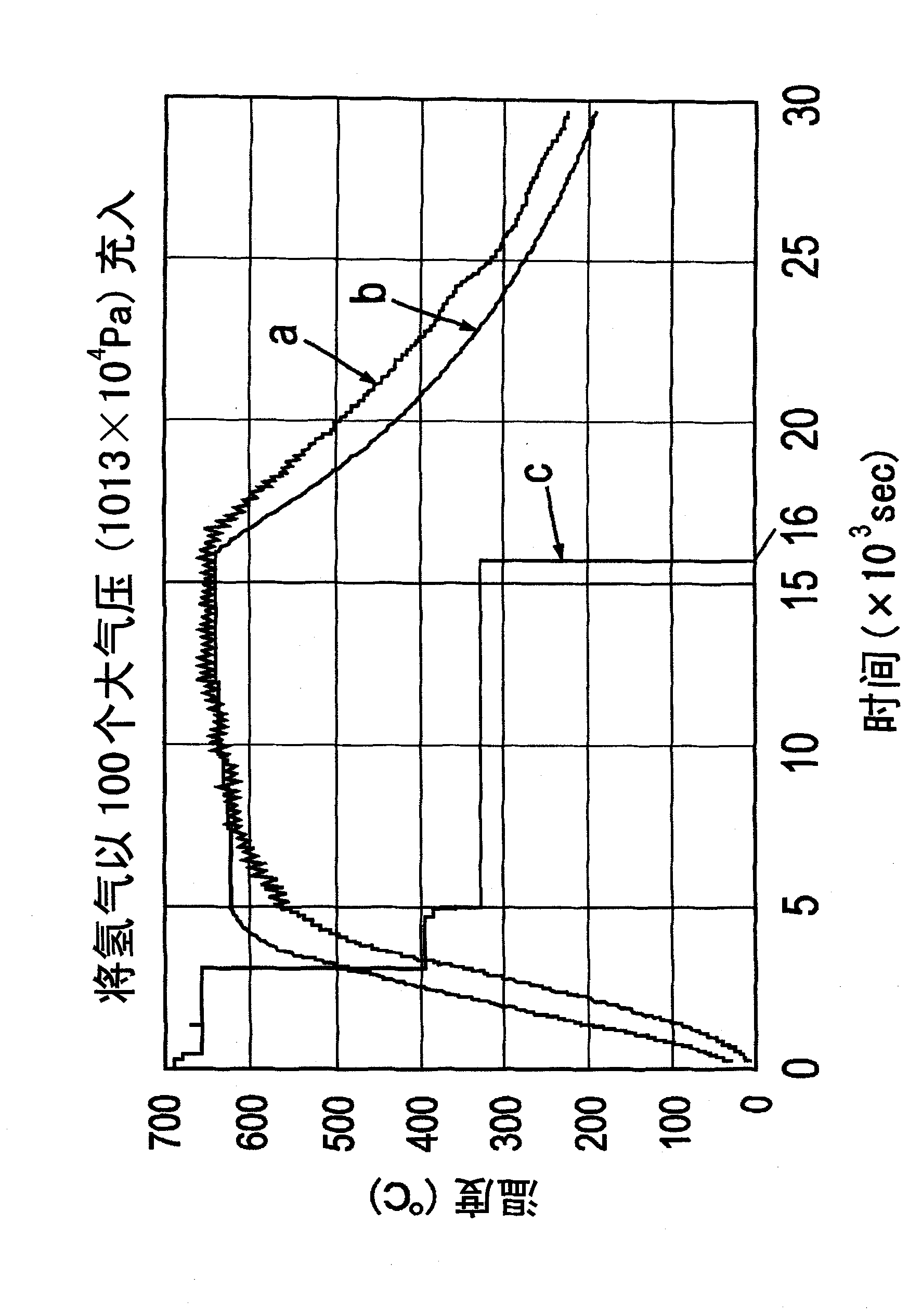

[0042] Thereafter, while the hydrogen supply valv...

Embodiment 2

[0052] Using the autoclave and heating device composed of the reactor 1 used in the above-mentioned Example 1, a nickel sintered body and 1 cc of creosote oil were charged as a catalyst into the autoclave main body 2a, and the hydrogen gas was set by the same operation as in the above-mentioned Example 1. is 1 atmosphere (10.13×10 4 Pa), and set helium to 70 atmospheres (7091×10 3 Pa), the temperature b of the outer wall surface of the autoclave main body 2a was set to 640°C. After 4 hours and 12 minutes, the internal temperature a of the autoclave main body 2a was about 30 degrees higher than the set temperature, and an exothermic reaction was confirmed. As a result of analyzing the solid matter remaining in the autoclave main body 2a after the reaction, it was confirmed that more than 50% of the carbon is a stable isotope of carbon 13 c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com