High-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester type polyurethane thermoplastic elastomer composition

A thermoplastic elastomer, flame retardant polyester technology, used in conductors, insulated conductors, electrical components and other directions, to improve high temperature and high humidity precipitation performance, good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

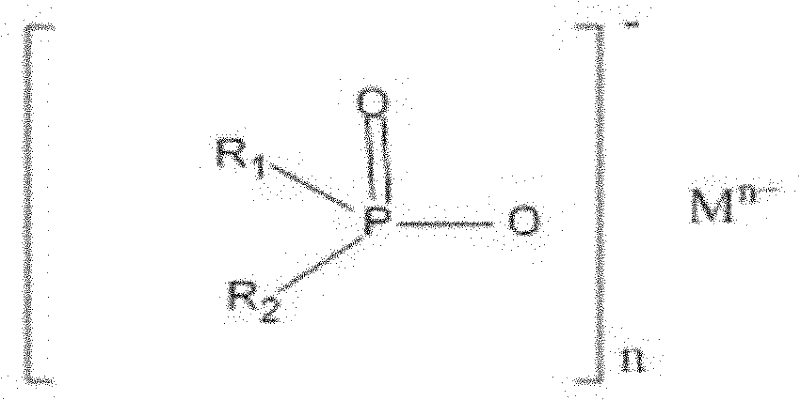

Image

Examples

Embodiment 1

[0036] The weight proportion of the flame-retardant polyester type thermoplastic polyurethane composition is as follows:

[0037] Aluminum Diethylphosphinate 20.0%,

[0038] Melamine Urocyanate 5.0%,

[0039] Viscosity modifier 8.0%,

[0040] Blend of antioxidants and UV absorbers 0.5%,

[0041] Polyester polyurethane elastomer (Shore A 85, tensile strength is about the balance.

[0042] 35MPa)

[0043] The viscosity regulator is an oil-extended styrene / conjugated diene copolymer, and the filling ratio of mineral oil processing oil is 100:100.

[0044] after mixing in On the twin-screw extruder, mix and granulate at a temperature range of 120-200°C to obtain a high-temperature, high-humidity, halogen-free, flame-retardant polyester polyurethane thermoplastic elastomer.

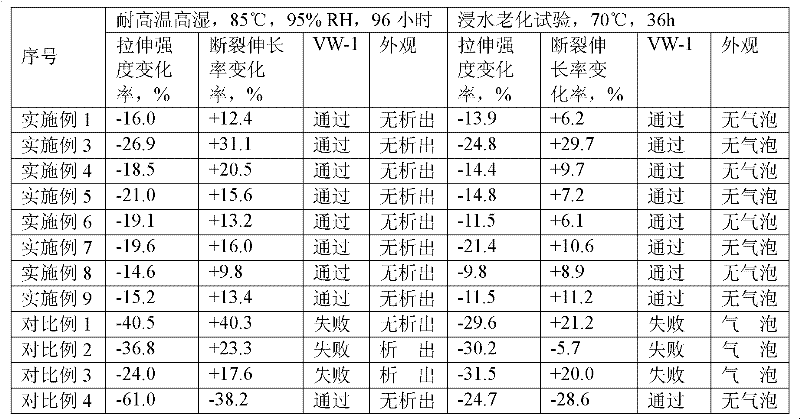

Embodiment 2~7

[0045] Embodiment 2~7: other composition and processing method are the same as embodiment 1.

[0046] serial number

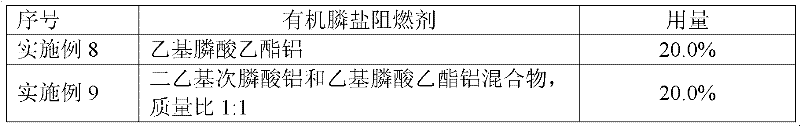

Embodiment 8-9

[0047] Embodiment 8-9: other ingredients and processing method are the same as embodiment 1.

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com