Elastic conductive composite fiber and preparation method thereof

A composite fiber, elastic and conductive technology, which is applied in fiber processing, fiber type, textile and paper making, etc., can solve the problems of ordinary fibers losing mechanical properties, conductive coatings are easy to fall off, and easy to damage fiber structures, etc., to achieve the preparation process and equipment The effect of simple and easy operation, long-lasting conductivity, and wide application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

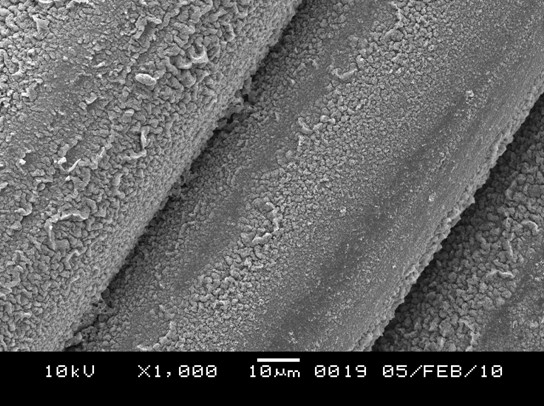

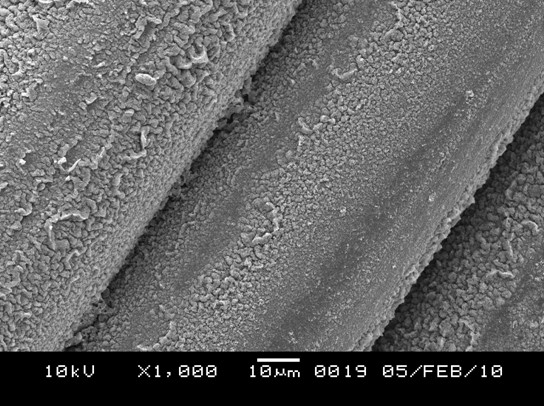

[0023] After deoiling the commercialized polyurethane fiber, take it out and dry it; pretreat the carbon black (particle size 50nm), and configure the carbon black / tetrahydrofuran dispersion, in which the carbon black accounts for 10wt%, and the treatment agent is 5wt%, the treatment agent is 0.01wt% hydrochloric acid solution, ultrasonic for 30 minutes to make it uniformly dispersed. Immerse the polyurethane fiber in the carbon black / tetrahydrofuran dispersion, the temperature is controlled at 20°C; ultrasonically act for 10s, the frequency is 35kHz, the power is 50W, take it out, wash it with deionized water, dry it to remove the treatment agent and solvent, and obtain the composite conductive fiber, the cortex The weight ratio to the core layer is 10:90. The conductivity of this composite fiber is 10 -7 W -1 cm -1 , The elongation at break is 1500%.

Embodiment 2

[0025] After the commercial polyurethane fiber is deoiled, it is taken out and dried; the graphite (particle size 50nm) is pretreated, and the graphite / dimethylformamide dispersion is prepared, and the graphite accounts for 10wt%. 5wt%, the treatment agent is 1wt% hydrochloric acid solution, ultrasonic 30 minutes to make it uniformly dispersed. Immerse the polyurethane fiber in the graphite / dimethylformamide dispersion, control the temperature at 40°C, apply ultrasonic for 500s, frequency 53kHz, power 250W, take it out, wash it with deionized water, dry it to remove the treatment agent and solvent, and obtain a composite conductive Fiber, skin to core weight ratio is 10:90. The conductivity of this composite fiber is 10 -2 W -1 cm -1 , The elongation at break is 1500%.

Embodiment 3

[0027] After the commercial polyurethane fiber is deoiled, it is taken out and dried; the graphene (particle size 100nm) is pretreated, and the graphene / dimethylacetamide dispersion is prepared, and the share of graphene is 10wt%. , the treating agent is 5wt%, and the treating agent is 0.01wt% hydrochloric acid solution, which is ultrasonically dispersed for 30 minutes to make it uniformly dispersed. Immerse the treated polyurethane fibers in the graphene / dimethylacetamide dispersion, the temperature is controlled at 40°C; ultrasonication is applied for 10s, the frequency is 35kHz, and the power is 100W. Take it out, wash it with deionized water, and dry it to remove the treatment agent and solvent , to obtain a composite conductive fiber, the weight ratio of the skin layer to the core layer is 10:90, and the conductivity of the composite fiber is 10 -3 W -1 cm -1 , The elongation at break is 1500%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com