Ionic liquid nanolayer of laser printer rubber covered roller, rubber covered roller and preparation method thereof

A technology of laser printers and ionic liquids, applied in the fields of optics, electrical recording process equipment using charge graphics, and electrical recording technology, can solve the problem of high-quality draft printing and high-definition requirements, developing rollers and charging rollers Difficult to meet high electrical conductivity, rubber roller roughness, resilience and hardness effects, etc., to achieve high-quality print output, good electrical conductivity, and high mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

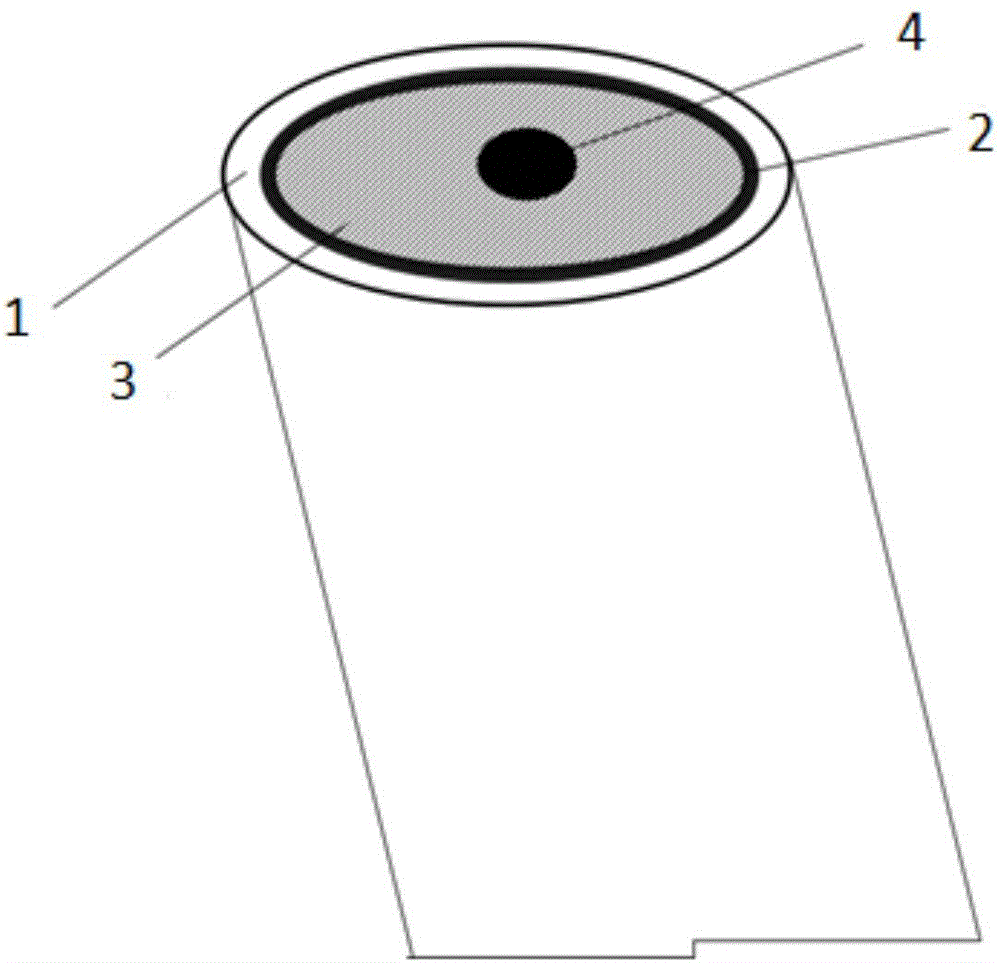

[0037] The present invention also provides a preparation method for the above-mentioned laser printer rubber roller, comprising the steps of:

[0038] S1 Clean the surface of the laser printer rubber roller with only rubber body (not sprayed with conductive paint) with a surfactant (such as detergent, etc.), and then rinse the surfactant with clean water until the surfactant is completely removed;

[0039] S2 Dry the rubber roller treated in step S1 with an air gun, then place the rubber roller in the plasma generator, first vacuum 0-30Pa, feed air, adjust the pressure to 10-50Pa, and turn on the plasma generator. Plasma generator, the rubber roller is subjected to plasma treatment, the treatment power is 50-300W and the treatment time is 30s-200s;

[0040] S3 Place the rubber roller on a dipping machine with a rotating speed of 50rpm-1000rpm, immerse it in the small molecule ionic liquid or / and ionic liquid polymer, or the mixture of the above-mentioned liquid or the mixture ...

Embodiment 1

[0045] S1 Use a surfactant to clean the rubber roller that only has a rubber body (silicone rubber), and then rinse it with clean water until the surfactant is completely removed;

[0046] S2 Dry the rubber roller with an air gun. The plasma machine is first evacuated to 25Pa, and air is introduced to adjust the pressure to 50Pa. Then, the rubber roller is placed in the plasma machine for plasma treatment. The treatment time is 120s and the treatment power is 90W;

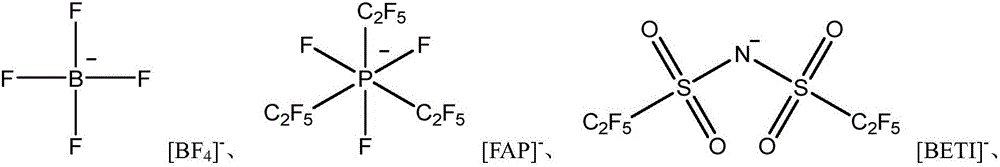

[0047] S3 fixes the silicone rubber cot after the last step on the dipping machine, and the ionic liquid polymer is (n=7) 20 parts, dilute with 10 parts of ethanol solvent, immerse the rubber roller in the ionic liquid polymer after dilution, dip coater is adjusted to rotating speed 100rpm, time 3s, at this moment ionic polymer nano-layer thickness is about 20nm, after standing for 20min, place it in a warm drying oven at 100°C and dry for 60min;

[0048] In S4, the outer periphery of the rubber roller after dryi...

Embodiment 2

[0050] S1 Use a surfactant to clean the rubber roller with only rubber body (synthetic rubber), then rinse with water until the surfactant is completely removed;

[0051] S2 Dry the rubber roller with an air gun. The plasma machine is first evacuated to 20Pa, and air is introduced to adjust the pressure to 40Pa. Then, the rubber roller is placed in the plasma machine for plasma treatment. The treatment time is 200s and the treatment power is 70W;

[0052] S3 Fix the synthetic rubber roller treated in the previous step on the dipping machine, and use ionic liquid A total of 30 parts (the ratio of the two is 5:3), the rubber roller is immersed in the diluted ionic liquid, the dipping machine is adjusted to a rotating speed of 200rpm, and the time is 15s. At this time, the thickness of the ionic liquid nano layer is about 15nm. Dry in a warm drying oven at a temperature of 80°C for 60 minutes;

[0053] S4 After the drying in the previous step, the outer circumference of the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com