Method for using rice hulls as fuel of cement kiln

A technology of cement kiln and rice husk, which is applied in the direction of combustion method, fuel supply, block/powder fuel preparation, etc. It can solve the problem that rice husk is not easy to burn completely, affects the quality of cement clinker, and the released calorific value is unstable, etc. problem, to achieve the effect of stable calorific value, complete combustion and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings. The above and other objects, features and advantages of the present invention will be apparent to those skilled in the art from the detailed description of the present invention.

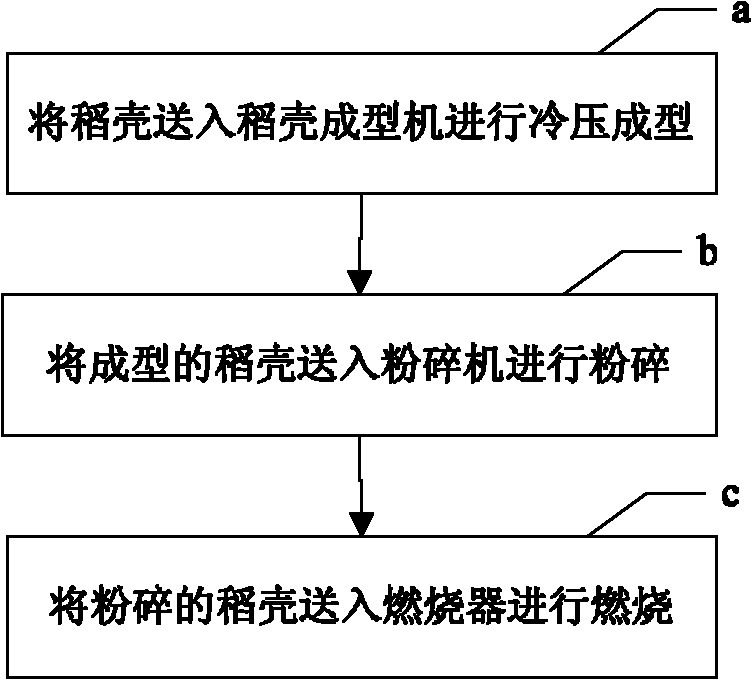

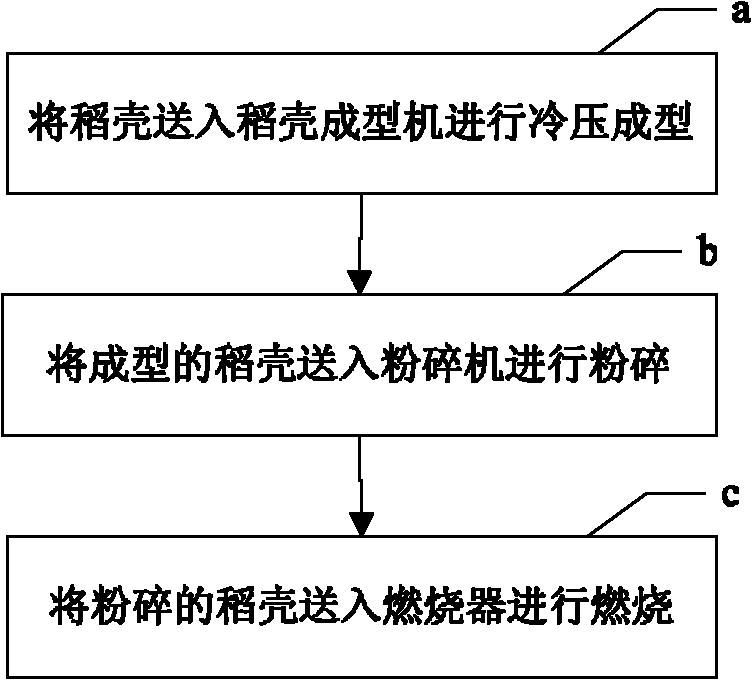

[0024] Such as figure 1 Shown, the present invention comprises the following operations with rice husk as cement kiln fuel method:

[0025] a: send the rice husk into the rice husk forming machine for cold pressing;

[0026] In the pellet forming process a, the rice husk is at a certain temperature, and its main component lignin is softened, resulting in an increase in cohesive force. Under a certain pressure, the cellulose molecular clusters are dislocated, deformed, and extended, and the adjacent biomass particles inside are engaged with each other, recombined and pressed into shape.

[0027] Cold pressing can form various shapes of rice husks, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com