Microwave power distributor

A technology of microwave power and splitter, which is applied in the direction of waveguide devices, electrical components, connecting devices, etc., can solve the problems of limited application range, large volume, and large loss, and achieve low insertion loss, high synthesis efficiency, and simple processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

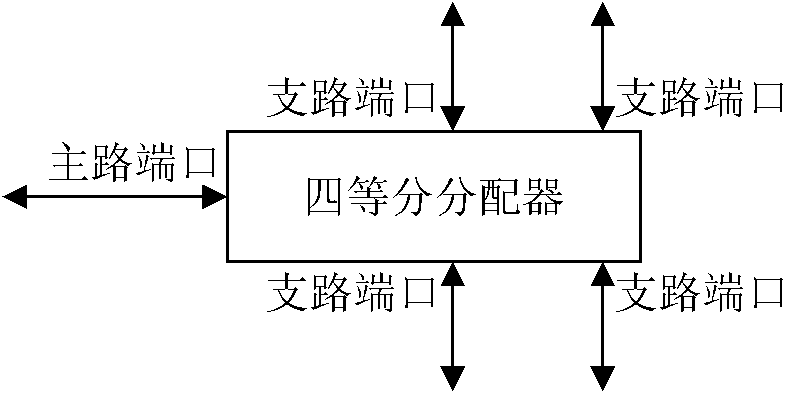

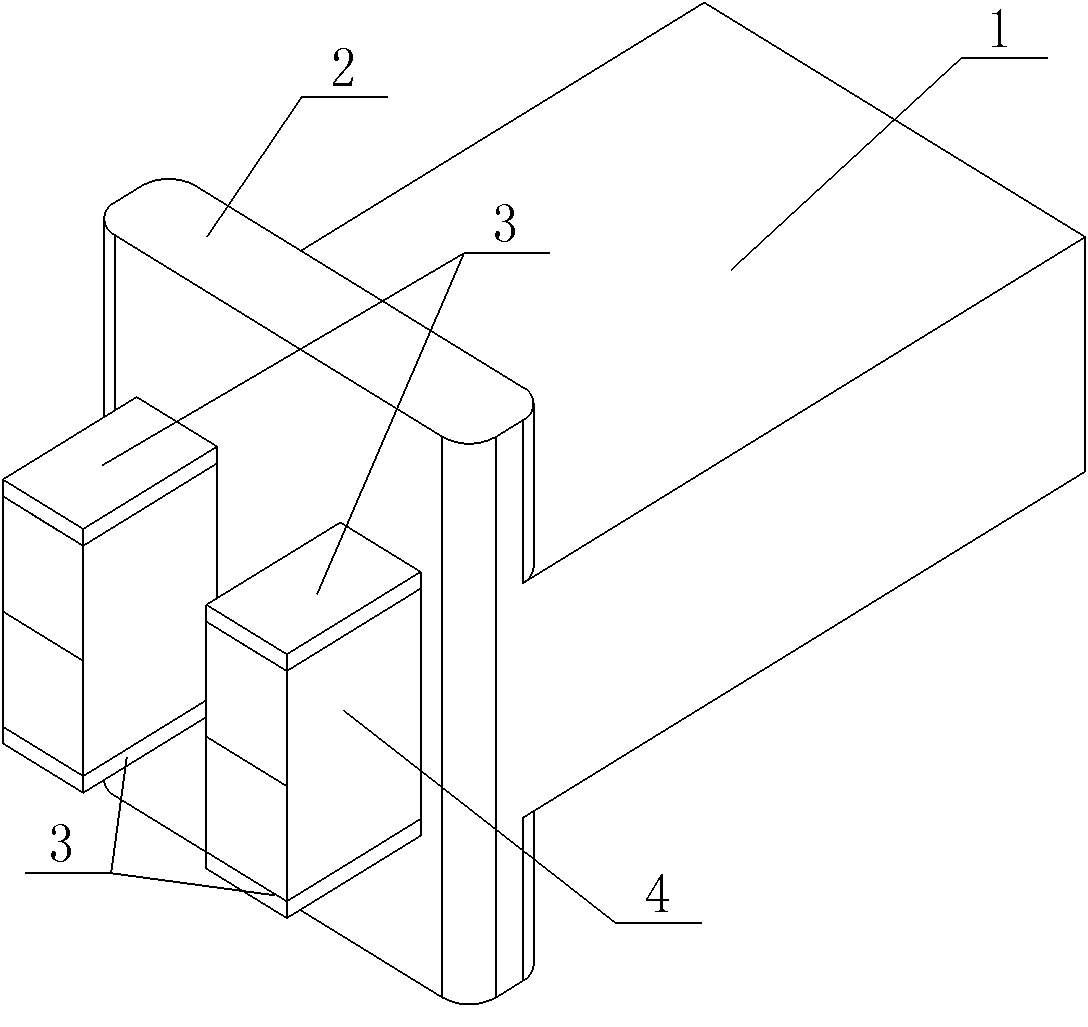

[0029] see Figure 3 ~ Figure 6 , the microwave power divider in this example is a quarter divider. Its cavity structure includes a rectangular waveguide cavity 1 and a coupling cavity 2. The coupling cavity 2 is a regular square prism, and its four edges have been chamfered to become smoother. , but keep the basic shape of the regular quadrangular prism, see image 3 and Figure 5 . The central part of one cylindrical surface of the coupling cavity 2 connects with the rectangular waveguide cavity 1 at the terminal short-circuit surface of the rectangular waveguide cavity 1 to form a whole, and the rectangular waveguide cavity 1 and the coupling cavity 2 are completely communicated. There are 4 windows on the cylinder opposite to the cylinder of the coupling cavity 2, and a coupler 3 is inserted in each window for coupling microwave signals. The microwave power divider in this example has a plane symmetrical structure, and its two orthogonal symmetrical planes ( Figure 4 ...

Embodiment 2

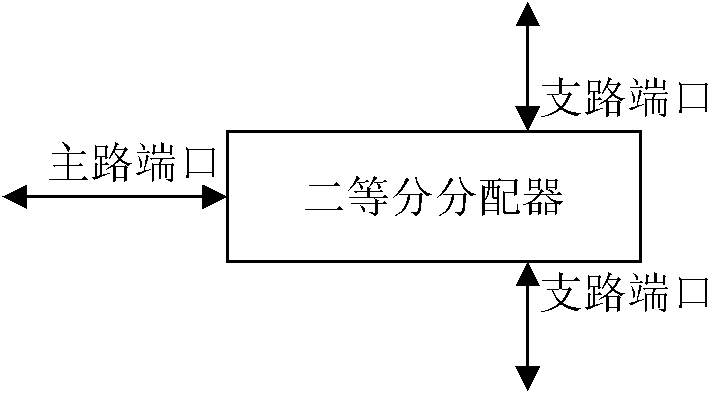

[0033] In this example, the number of microwave power splitter windows is 2, and of course there are also 2 couplers, such as Figure 10shown. This is a bisecting divider with a plane-symmetric structure, and its symmetry plane is perpendicular to the short-circuit surface of the waveguide cavity terminal. The microwave power divider in this example is divided into two parts, each of which has a window. Figure 10 The two couplers in the middle are arranged vertically, the microstrip line on the ceramic substrate of the upper coupler is downward, and the microstrip line on the ceramic substrate of the lower coupler is upward. Obviously, Figure 10 The two couplers in the middle can also adopt a lateral configuration structure, and the microstrip lines on the ceramic substrate of the coupler are arranged opposite to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com