Dried konjac and manufacturing method therefor as well as processed foods using said dried konjac

A technology for processed food and konjac, which is applied in the field of dried konjac and its manufacture and processed food using the dried konjac, can solve problems such as dissolution, and achieve the effects of good water development, efficient drying and inhibition of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

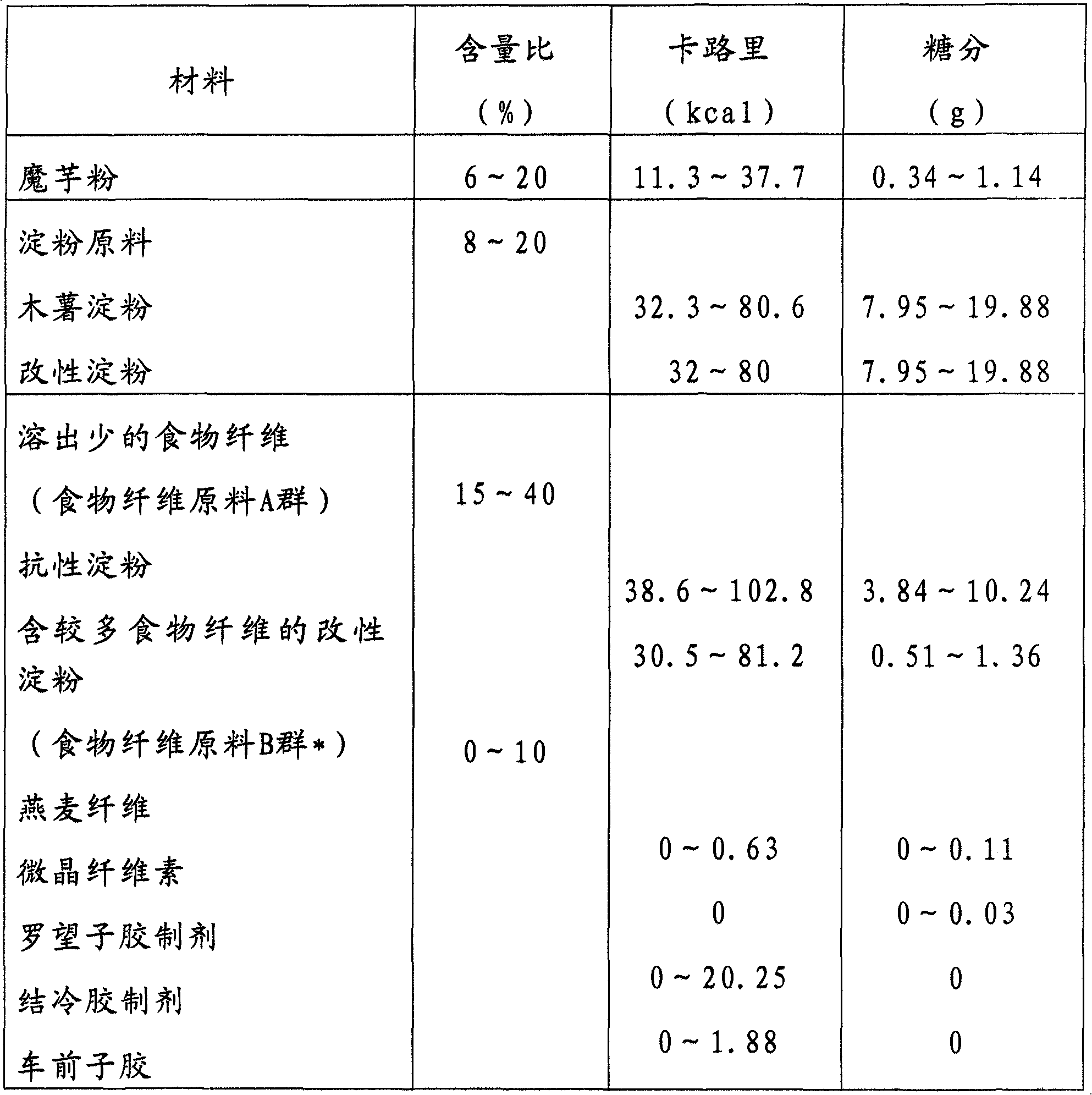

[0089] The dry konjac obtained by the present invention is obtained according to the ingredient ratio shown in Table 2-1 in Example 1 and the data of calories and sugar content.

[0090] Below, blank

[0091] 【table 2-1】

[0092]

[0093] The manufacturing method of the dried konjac shown in Example 1 is as follows.

[0094] (Manufacturing process of rice-shaped konjac gel)

[0095] Utilize common means to be the mixture of 2.5% konjac flour by weight, 4% tapioca starch, 5% modified starch containing more dietary fiber and 88.5% water by weight ratio to prepare Rice-shaped konjac. That is, a predetermined amount of water is added to a mixture of konjac flour, starch raw material, and dietary fiber raw material to disperse and dissolve it. After standing still at room temperature, add lime milk while stirring and mixing, and form granules with a diameter of 3 to 5 mm through the rotary nozzle of the konjac konjac forming machine. Put it into hot water at 60° C. and stir...

Embodiment 2

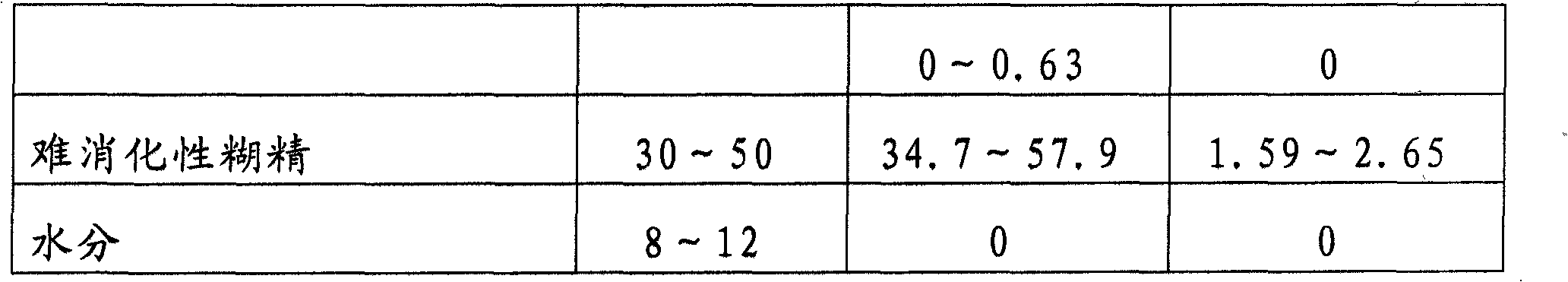

[0115] Obtain the dry konjac of the present invention of using material shown in Table 2-2, content ratio in embodiment 2.

[0116] The manufacturing method uses different materials and blending ratios, but is obtained by the same manufacturing method as in Example 1.

[0117] 【Table 2-2】

[0118]

[0119]

Embodiment 3

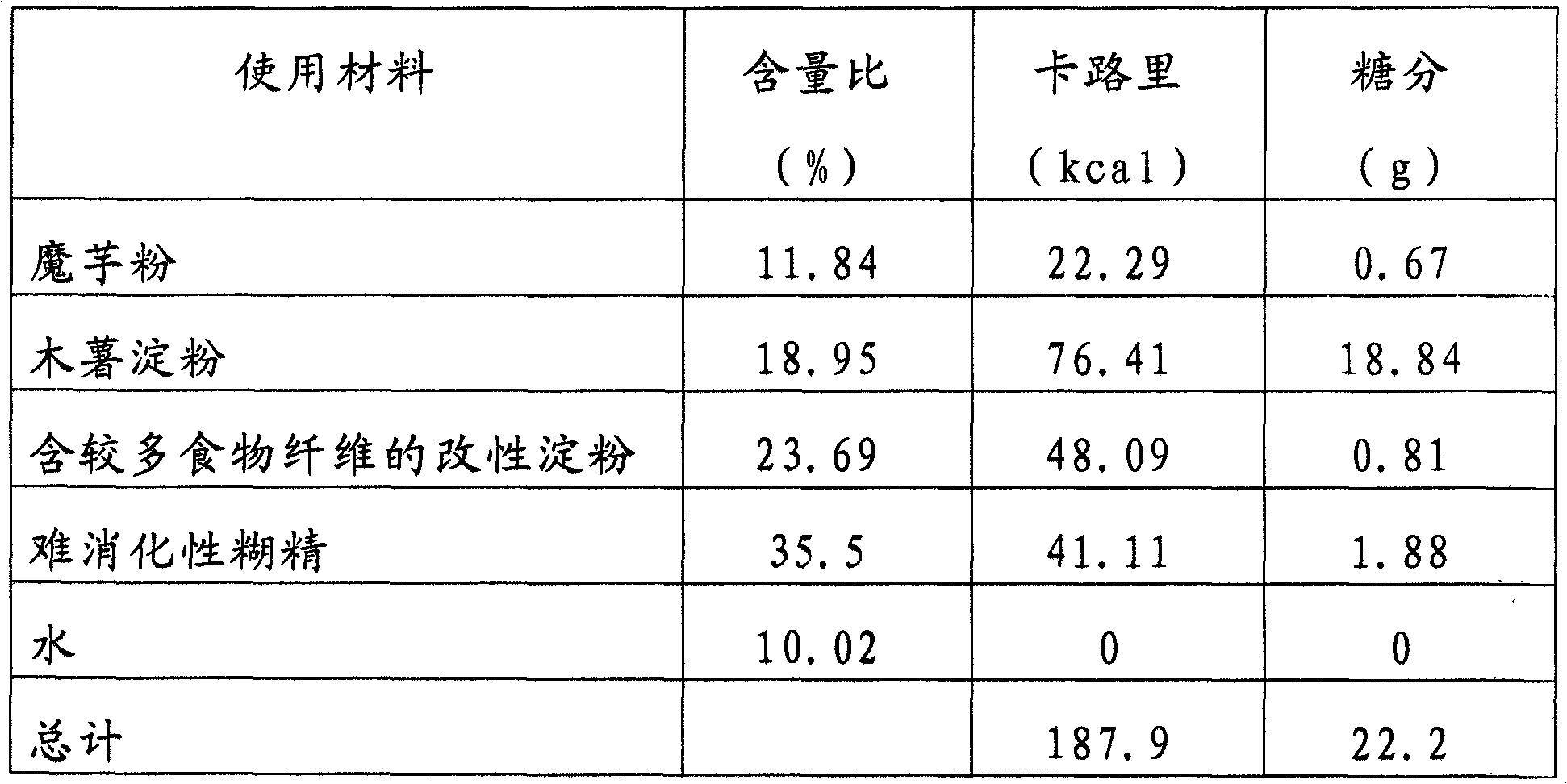

[0121] Obtain the dried konjac of the present invention using materials shown in Table 2-3, content ratio in embodiment 3.

[0122] The manufacturing method uses different materials and blending ratios, but is obtained by the same manufacturing method as in Example 1.

[0123] 【Table 2-3】

[0124]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com