Method for reinforcing nitrogen and phosphorous removal from sewage by utilizing anaerobic environment of pipeline

A technology for denitrification, phosphorus removal, and sewage, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve enhanced denitrification, strong practicability and guaranteed denitrification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

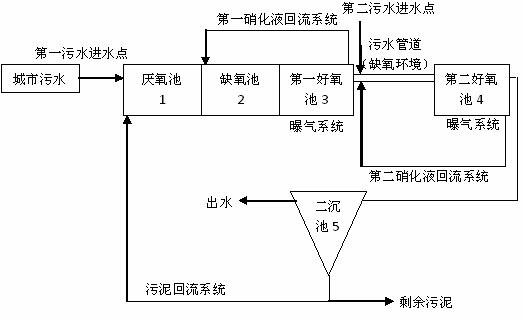

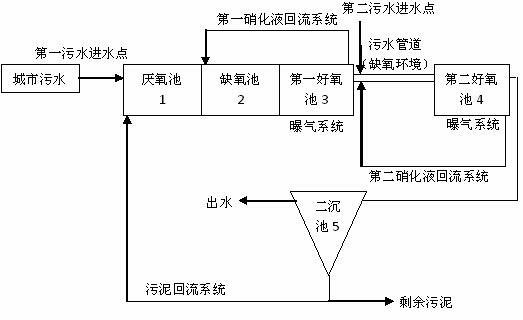

Image

Examples

Embodiment 1

[0022] Embodiment 1: Under normal conditions, the influent water quality of a treatment plant in Pudong, Shanghai: COD is 100-180mg / L, ammonia nitrogen is 15-25mg / L, total nitrogen is 20-35mg / L, and total phosphorus is 1.0-4.0 mg / L. Adopt 50% reflux ratio of nitrification liquid and 100% sludge reflux ratio, control the dissolved oxygen in the first aerobic tank 3 and the second aerobic tank 4 at 1.5mg / L, the effluent water quality can reach: COD below 20mg / L , the removal rate is about 10-15%, the total nitrogen is 10-15mg / L, the total phosphorus is below 1.2mg / L, and the ammonia nitrogen removal rate is over 96%.

Embodiment 2

[0023] Example 2: The treatment effects of this process were investigated respectively for the high-concentration influent and low-concentration influent of a sewage treatment plant in Pudong, Shanghai. Under high-concentration influent conditions, the influent COD is 178.74mg / L, TN is 35.75mg / L, TP is 2.55mg / L, ammonia nitrogen is 31.47mg / L, and TSS is 343mg / L. After system treatment, the effluent COD TN was 21.41mg / L, TN was 19.51mg / L, TP was 1.26mg / L, ammonia nitrogen was 0.34mg / L, and TSS was 19mg / L. Under low-concentration influent water conditions, the influent COD is 99.93mg / L, TN is 19..99mg / L, TP is 1.43mg / L, ammonia nitrogen is 17.59mg / L, and TSS is 192mg / L. After system treatment, The effluent COD is 12.62mg / L, TN is 10.99mg / L, TP is 0.71mg / L, ammonia nitrogen is 0.37mg / L, and TSS is 11mg / L.

Embodiment 3

[0024] Example 3: For the influent water quality of a sewage treatment plant in Pudong, Shanghai in summer (June) and winter (January), the treatment effect of this process under different temperature conditions is: when the temperature is higher in summer (25°C), it can Ensure that the effluent TN is 5-15mg / L, TP is below 1.2mg / L, and COD is below 20mg / L, with an average removal rate of 55.0%, 51.0% and 88.9% respectively. Under low temperature conditions in winter (15°C), the nitrification process will be greatly affected. The effluent TN is basically maintained at about 10mg / L, TP is below 0.5mg / L, and COD is below 15mg / L. The average removal rate reaches 49.9%, 72.0% and 88.7%, the denitrification effect is not as good as that in summer, but due to the decrease of total phosphorus load, the phosphorus removal effect is stronger than that in summer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com