Method for recycling pyridine from chemical production wastewater

A technology for chemical production and wastewater, applied in organic chemistry, extraction water/sewage treatment, etc., can solve the problem of high treatment cost, achieve high removal rate, low cycle loss, and low water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

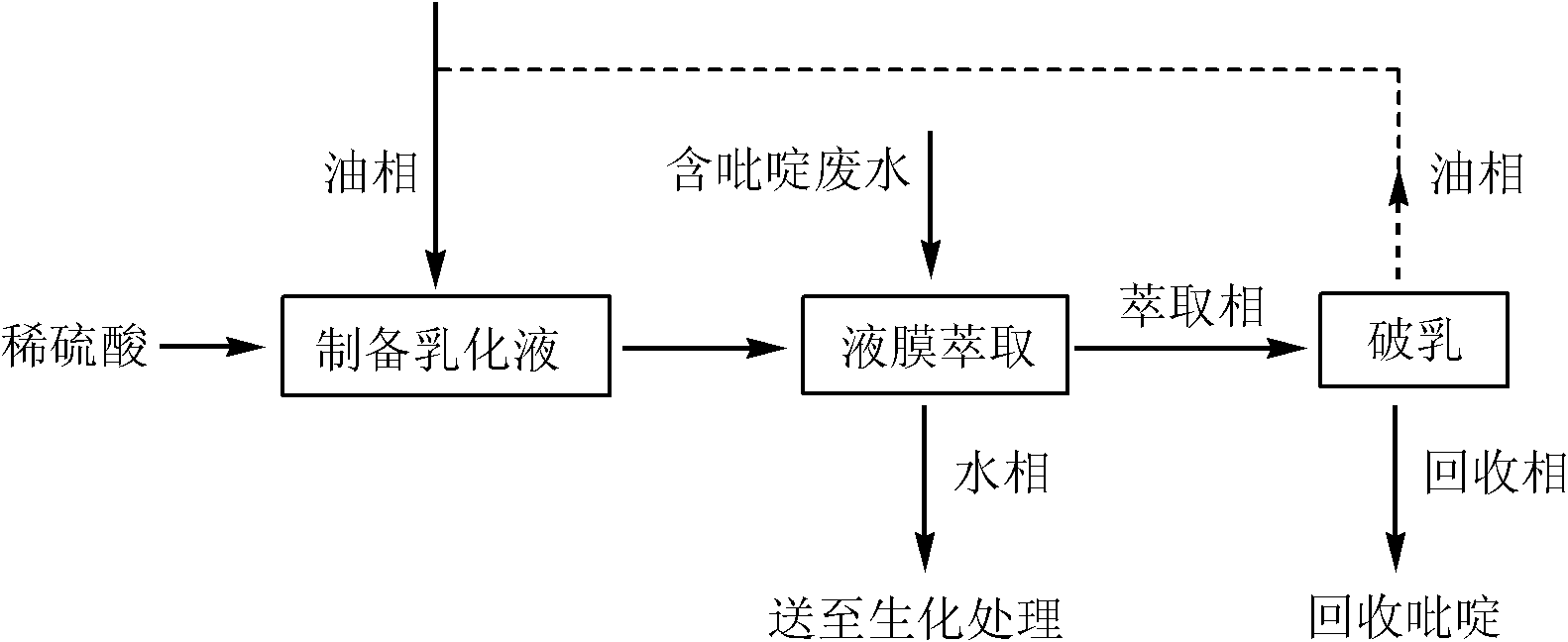

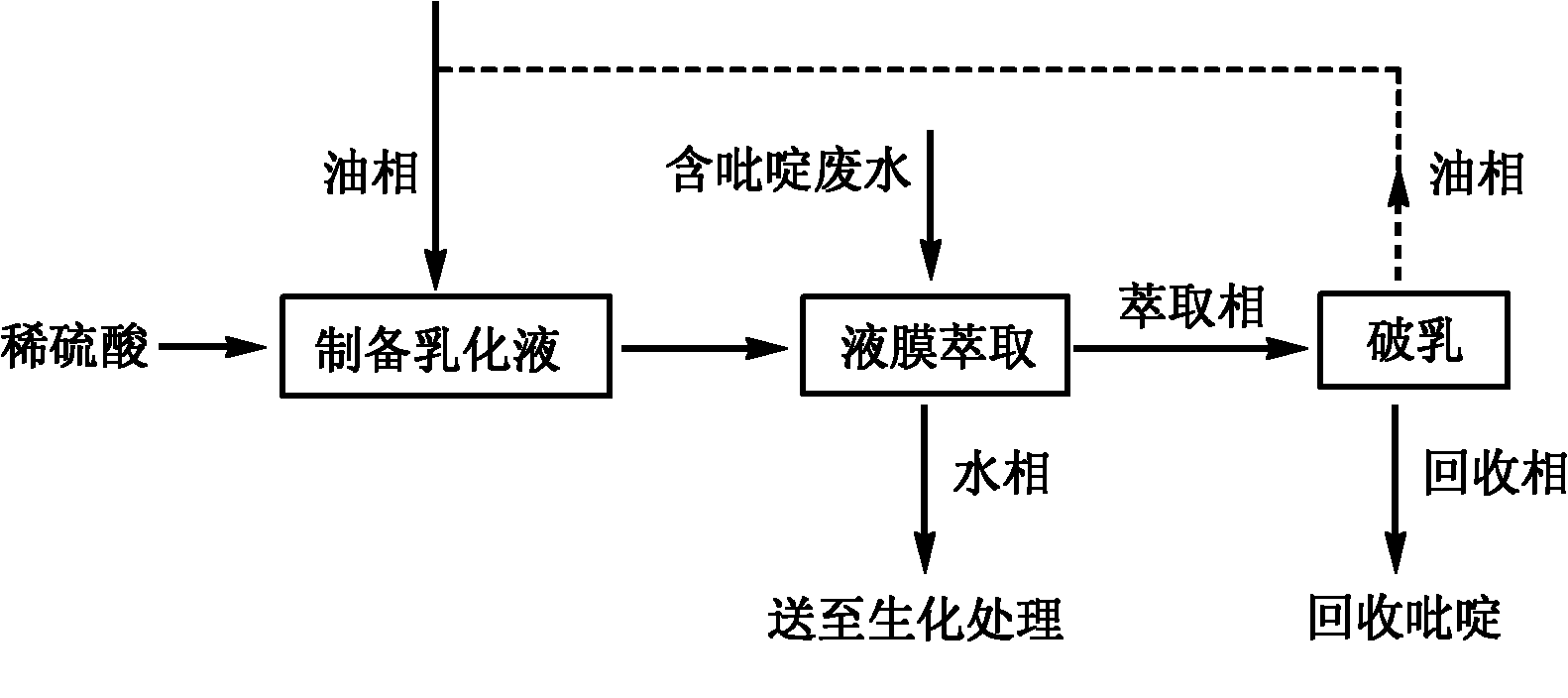

Method used

Image

Examples

Embodiment 1

[0022] The wastewater was taken from the paraquat production workshop of Jinan Lvba Chemicals Co., Ltd., with a pyridine concentration of 3000 mg / L and pH=10.

[0023] First, 1440L of aviation kerosene, 64L of surfactant L-113A and 96L of liquid paraffin were formulated into the oil phase, and put into 3m 3 In the emulsification kettle, start stirring, and add 800L of 15% dilute sulfuric acid as the water phase at the same time, and stir the oil-water two-phase at 2900 rpm for 30 minutes to obtain a stable W / O emulsion.

[0024] Then disperse 300L emulsion in 8m 3 In the paraquat wastewater, start stirring, control the speed of extraction at 120 rpm for 30 minutes, and let stand to separate layers. The upper layer is the extraction phase and enters the demulsification device; the lower layer is the treated wastewater. The pyridine concentration is 0.6mg / L after being sent to the biochemical treatment device for routine treatment.

[0025] The upper extraction phase is demuls...

Embodiment 2

[0027] Wastewater source is the same as embodiment 1.

[0028] First set the 1365m 3 Aviation kerosene, 45L surfactant L-113B and 90L liquid paraffin are prepared into the oil phase, put into 3m 3 Turn on the stirring of the emulsification kettle, and add 1000L of 15% dilute sulfuric acid as the water phase at the same time, and stir the oil-water two-phase at 2900 rpm for 30 minutes to obtain a stable W / O emulsion.

[0029] Then disperse 250L emulsion in 8m 3 In the paraquat wastewater, start stirring, control the speed of extraction at 120 rpm for 45 minutes, and let stand to separate layers. The upper layer is the extraction phase and enters the demulsification device; the lower layer is the treated wastewater. The pyridine concentration is 0.5 mg / L after being sent to the biochemical treatment device for routine treatment.

[0030] The upper extraction phase is demulsified under the action of the high-voltage electrostatic field in the demulsification device and divided...

Embodiment 3

[0032] The wastewater was taken from the production workshop of organophosphorus flame retardants of Nantong Jiangshan Chemical Co., Ltd., with a pyridine concentration of 15454 mg / L and a pH of 10-11.

[0033] First, 1440L of aviation kerosene, 64L of surfactant L113A and 96L of liquid paraffin were formulated into the oil phase, and put into 3m 3 Turn on the stirring of the emulsification kettle, and add 800L of 20% dilute sulfuric acid as the water phase at the same time, and stir the oil-water two phases at 2900 rpm for 30 minutes to obtain a stable W / O emulsion.

[0034] Then disperse 1000L emulsion in 8m 3 In the waste water to be treated, start stirring, control the rotation speed of 120 rpm to extract for 30 minutes, and let it stand for stratification. The upper layer is the extraction phase and enters the demulsification device; the lower layer is the treated wastewater. The pyridine concentration is 0.8mg / L after being sent to the biochemical treatment device for r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com