Method for increasing magnetoelectric property of gradient material

A gradient material, magnetoelectric technology, applied in the direction of device material selection, material selection for magnetostrictive devices, piezoelectric/electrostrictive device manufacturing/assembly, etc., can solve the problem of high material brittleness and material magnetoelectric properties Inconspicuous, poor material processing performance and other problems, to achieve the effect of increased magnetoelectric performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

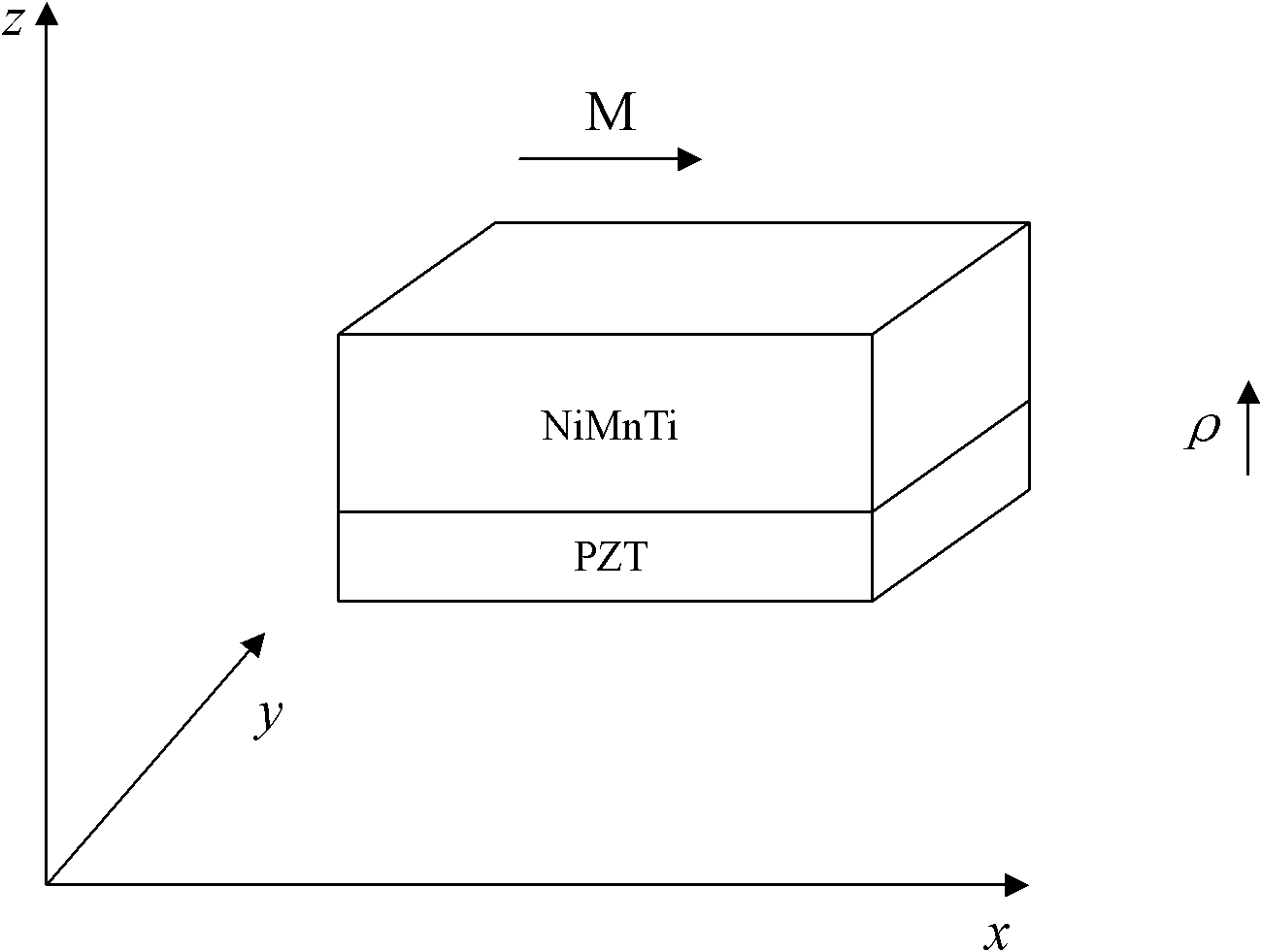

[0014] 1. If figure 1 , as shown in 2, the object of our research is the gradient material, which is composed of piezoelectric material PZT and nickel-based alloy, through the piezoelectric effect and the hysteresis effect to produce a product effect, to achieve magnetoelectric coupling, thus Improve the magnetoelectric coupling effect of the material.

[0015] 2. Use silver epoxy adhesive on the upper and lower surfaces of the PZT ceramic gradient sample, put it in a high-temperature furnace and bake it at 900°C for 36 minutes, polarize along the thickness direction, and bond it with Ni / Mn / Ti alloy. After solidification, the gradient material sample required by the present invention is obtained.

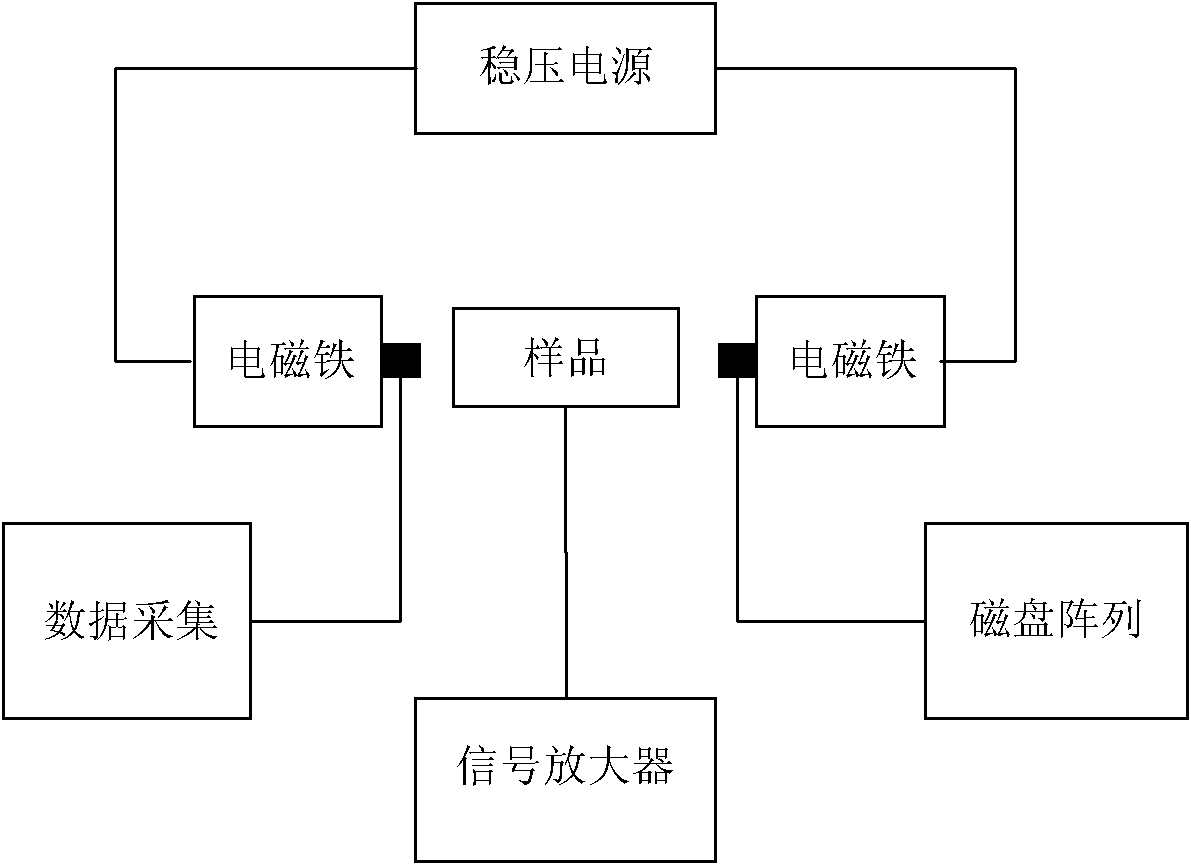

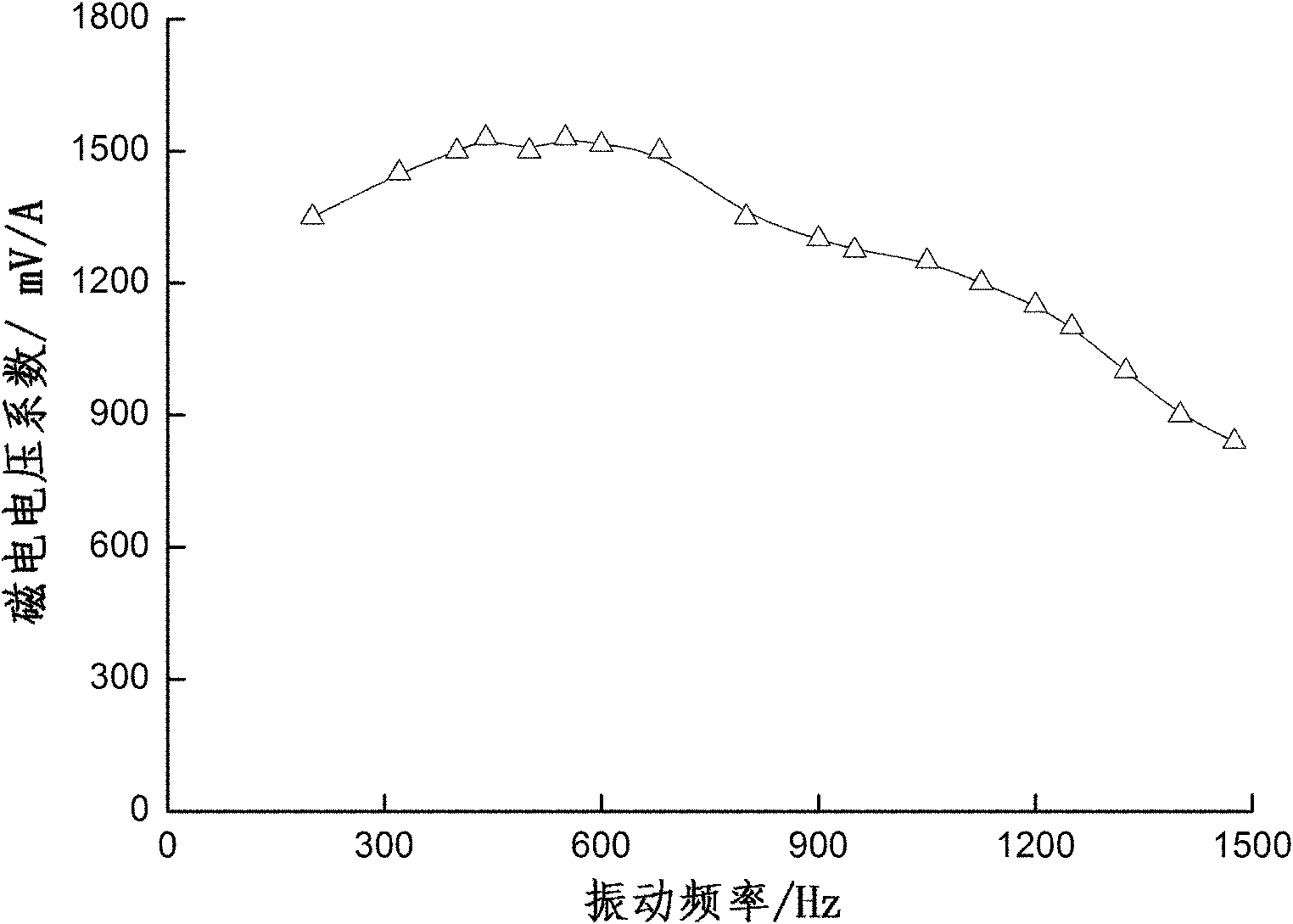

[0016] 3. The characteristic of the magnetoelectric property measurement system is 150Hz~1500Hz, and the DC bias field is 0~1.2P, which can realize variable temperature measurement. The sample is placed in the electromagnet and adjusted to room temperature, and its length directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com