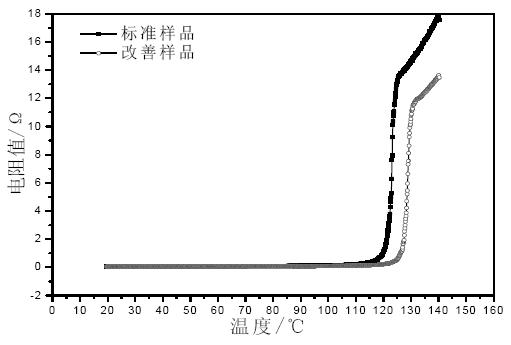

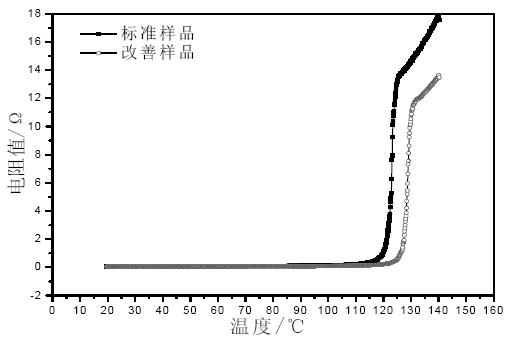

Conductive composite material for improving switching temperature of PTC (positive temperature coefficient) thermal element and manufacturing method thereof

A technology of conductive composite materials and heat-sensitive elements, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, resistors with positive temperature coefficients, etc., can solve the problem of PTC heat-sensitive elements not being able to maintain, and avoid structural Design, the effect of increasing the switching temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] A kind of conductive compound material that is used to improve the switch temperature of PTC thermosensitive element, is the compound material of polyolefin / carbon black, comprises by weight:

[0022] High-density polyethylene 48 parts

[0023] 52 parts of carbon black.

[0024] Among them, the high-density polyethylene has a crystallinity of not less than 70% and a density of not less than 0.94g / cm 3 ; The carbon black is lamp smoke black with large particle size and good conductivity, the particle size is 80-100nm, and the DBP oil absorption value is not less than 65ml / 100g.

[0025] The preparation method is as follows: mix the high-density polyethylene and carbon black in the internal mixer at a temperature of about 175°C at a low speed, the speed is 20 rpm, and the mixing time is 15 minutes. After hot pressing, the thickness is 0.30-0.32 mm sheet, irradiated once under the condition of a dose of 16Mrad to make a conductive composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com