Method for extracting naphthalene, 1-methylnaphthalene and 2-methylnaphthalene from ethylene tar

A technology for ethylene tar and methylnaphthalene, which is applied in the field of extracting high-purity naphthalene, 1-methylnaphthalene and 2-methylnaphthalene from petroleum cracking by-product tar, which can solve the problem of complex operation and uncertain products of alkylation reaction , a large amount of waste residue, waste water and other problems, to achieve the effect of easy automatic operation, conducive to environmental protection, and increase product content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

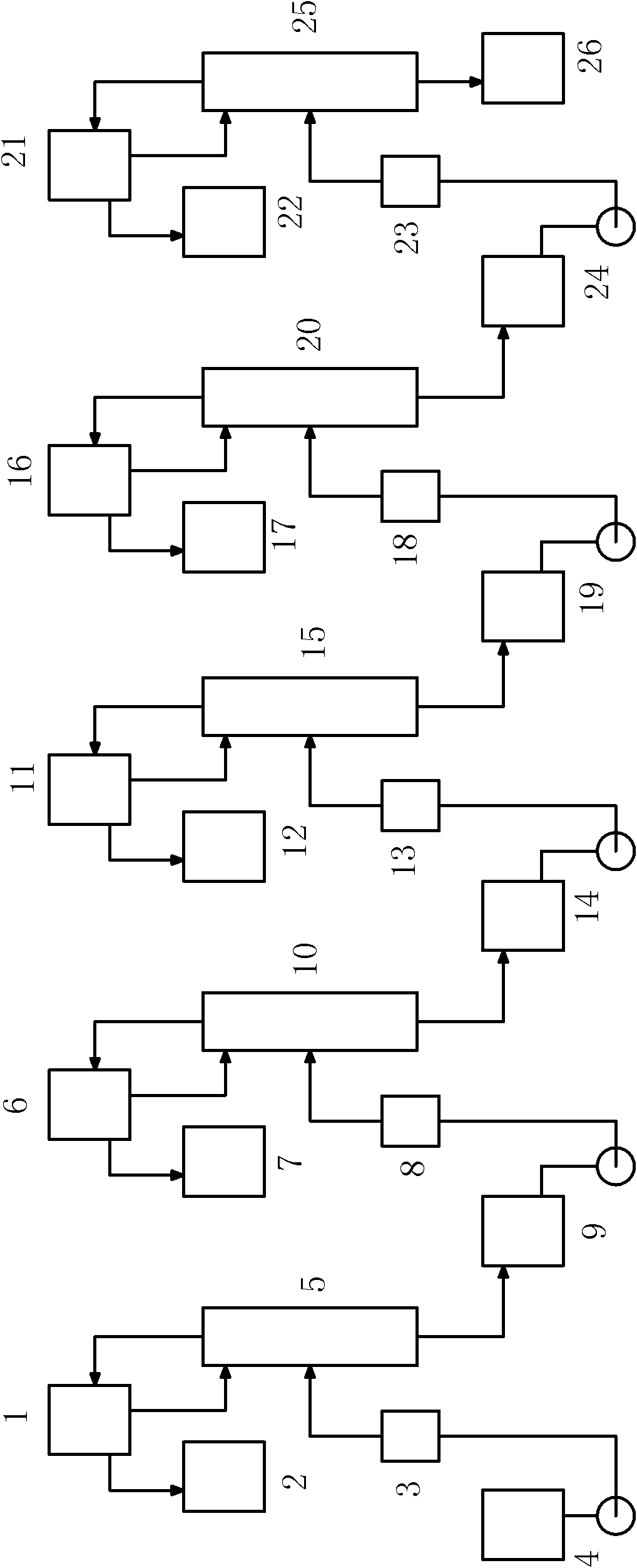

[0021] refer to figure 1 , containing naphthalene and methyl naphthalene total 30% ethylene cracking tar, pumped from the raw material storage tank 4 through the first feed heat exchanger 3 into the middle part of the first rectification tower 5, the operating pressure of the rectification tower 5 is 0.10 MPa, tower bottom temperature 238±2°C, tower top temperature 198±2°C, at the top of the rectification tower 5, light components with a boiling point lower than naphthalene are extracted through the first condensing reflux device 1, and enter the component storage tank 2 , the tower bottom material enters the first intermediate storage tank 9.

[0022] The material in the first intermediate storage tank 9 is pumped through the second feed heat exchanger 8 into the middle of the second rectification column 10 . The operating pressure at the top of the second rectifying tower 10 is 0.09MPa, the temperature at the bottom of the tower is 238 ± 2°C, and the temperature at the top ...

Embodiment 2

[0028] refer to figure 1 , containing naphthalene and methyl naphthalene total 30% ethylene cracking tar, pumped from the raw material storage tank 4 through the first feed heat exchanger 3 into the middle of the first rectification tower 5, the first rectification tower 5 tower top operation The pressure is 0.08MPa, the temperature at the bottom of the tower is 222±2°C, and the temperature at the top of the tower is 182±2°C. At the top of the first rectification tower 5, light components with a boiling point lower than naphthalene are extracted through the first condensing reflux device 1, and enter the light The component storage tank 2, the bottom material enters the first intermediate storage tank 9.

[0029] The material in the first intermediate storage tank 9 is pumped through the second feed heat exchanger 8 into the middle of the second rectification column 10 . The operating pressure at the top of the second rectifying tower 10 is 0.07MPa, the temperature at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com