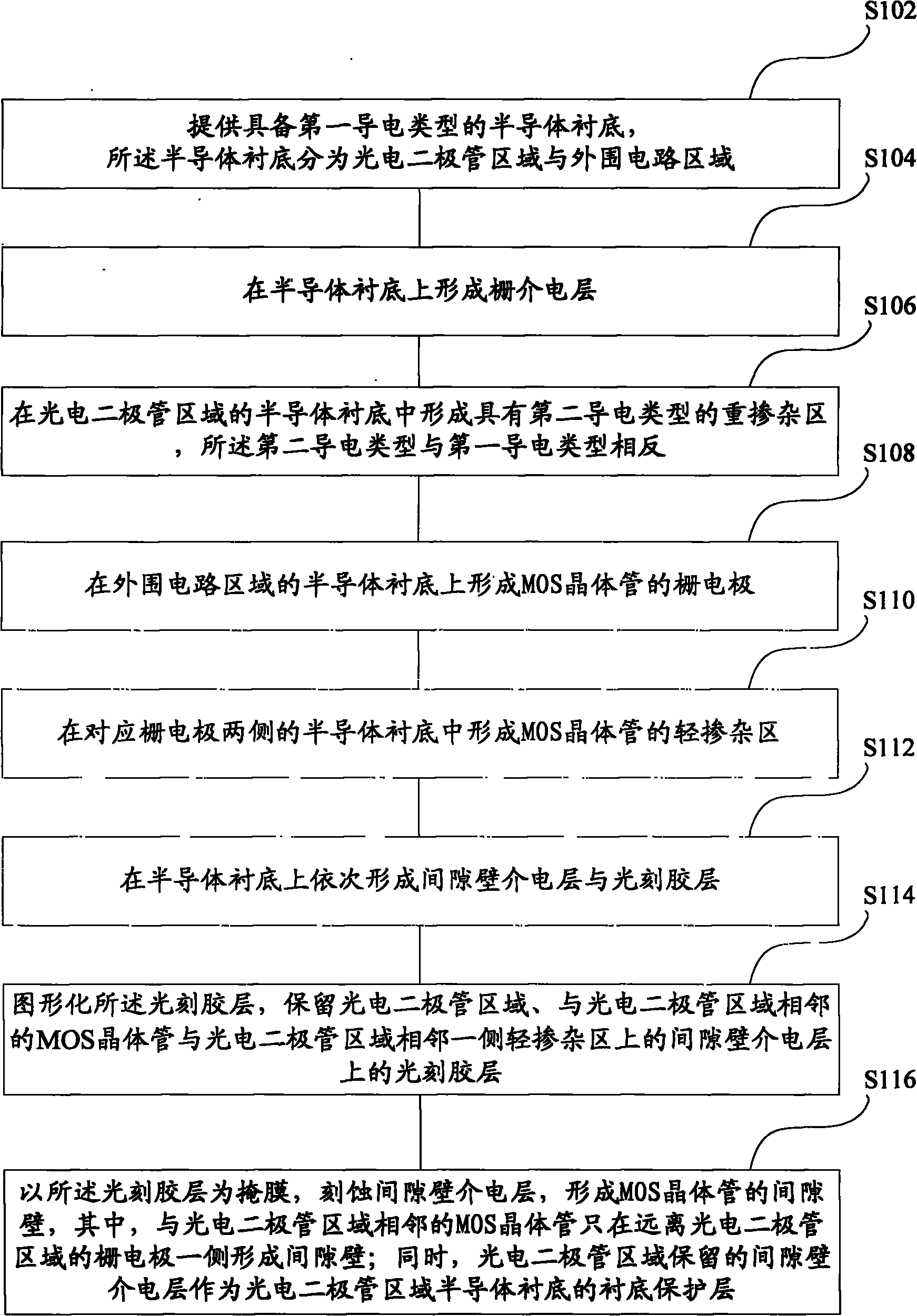

Method for manufacturing CMOS image sensor

A technology of an image sensor and a manufacturing method, which is applied in the field of semiconductors, and can solve problems such as substrate etching in the CMOS transistor area, increased leakage current of the MOS transistor, and failure of the MOS transistor to work normally, so as to reduce damage and avoid repeated etching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

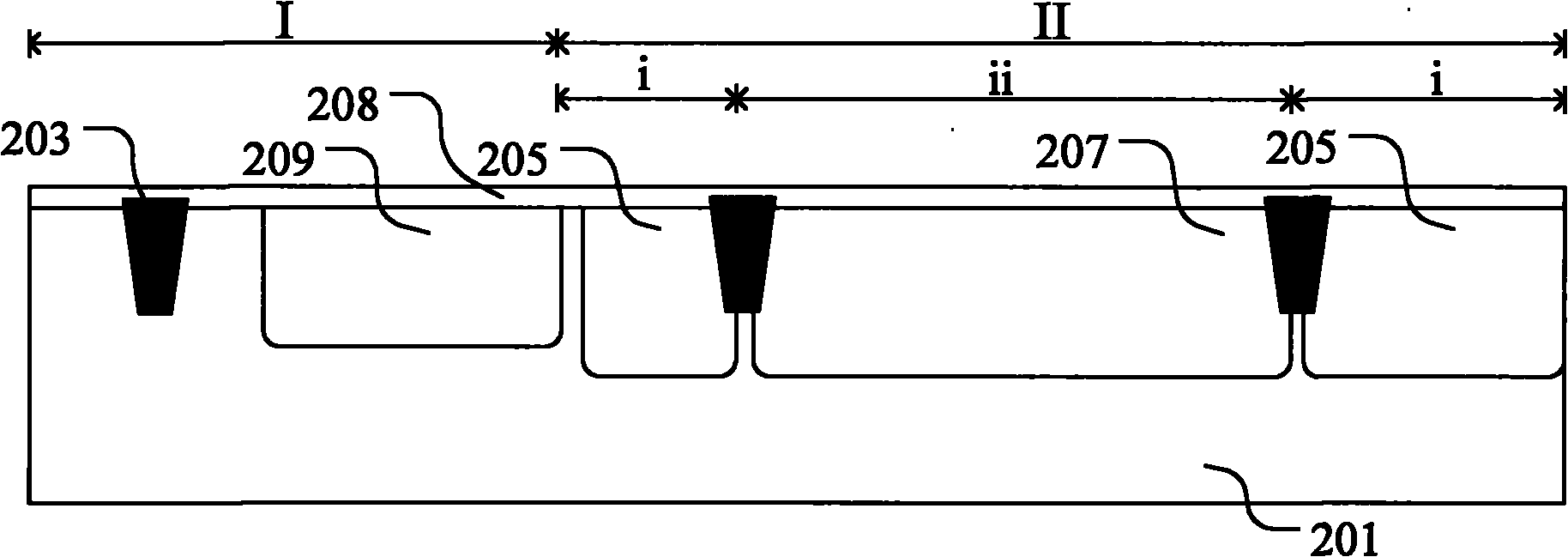

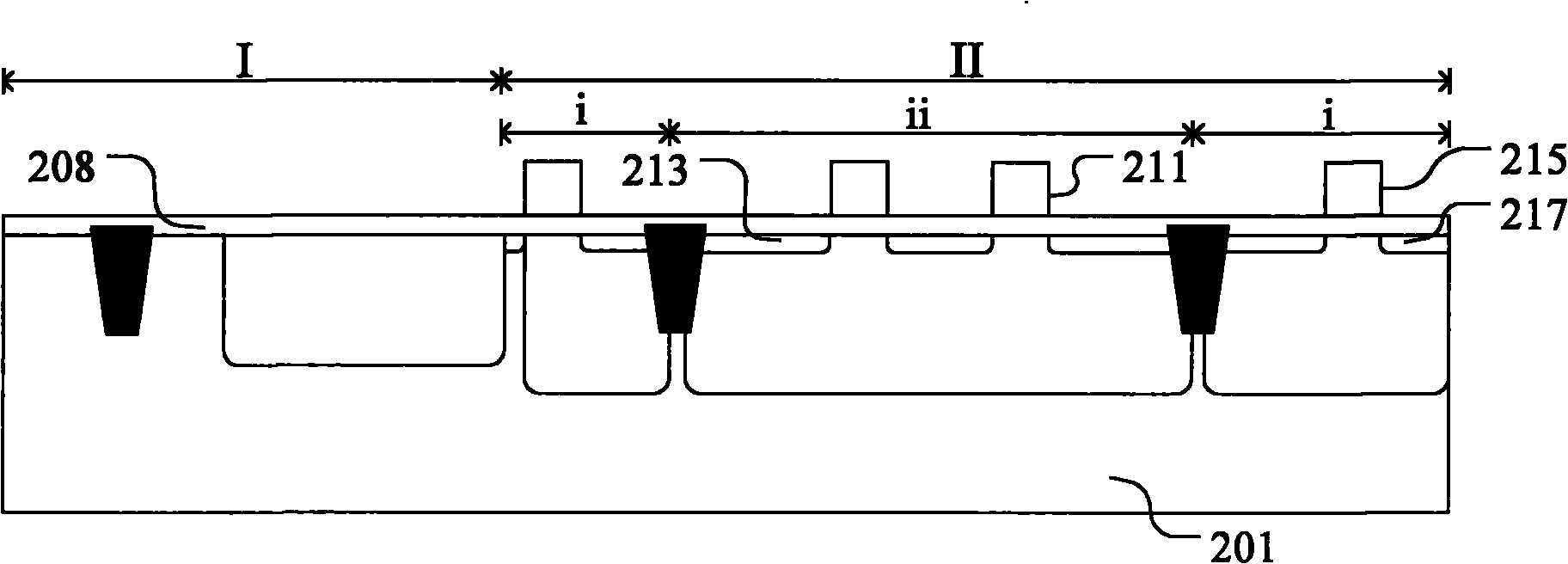

[0029] In the prior art, when manufacturing a CMOS image sensor, it is necessary to form a substrate protection layer on the semiconductor substrate in the photodiode region to protect the surface of the semiconductor substrate. The substrate protection layer is usually formed simultaneously with the spacers of the CMOS transistors, which requires two photolithography and etching processes, that is, the spacers of the PMOS transistors and the spacers of the NMOS transistors are formed respectively.

[0030] In the process of forming the MOS transistor spacer, if there is a deviation in the photolithographic alignment or an error in the subsequent photoresist development, the photoresist mask will have a pattern deviation, and the pattern deviation of the photoresist mask will make the semiconductor substrate The bottom is etched repeatedly, causing damage to the substrate. The damage of the semiconductor substrate will increase the leakage current of the MOS transistor, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com