Temperature control method of laser medium of disk laser and device thereof

A temperature control method and technology of thin-sheet lasers, which are applied to lasers, laser components, phonon exciters, etc., can solve problems such as improving beam quality, reducing laser output power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

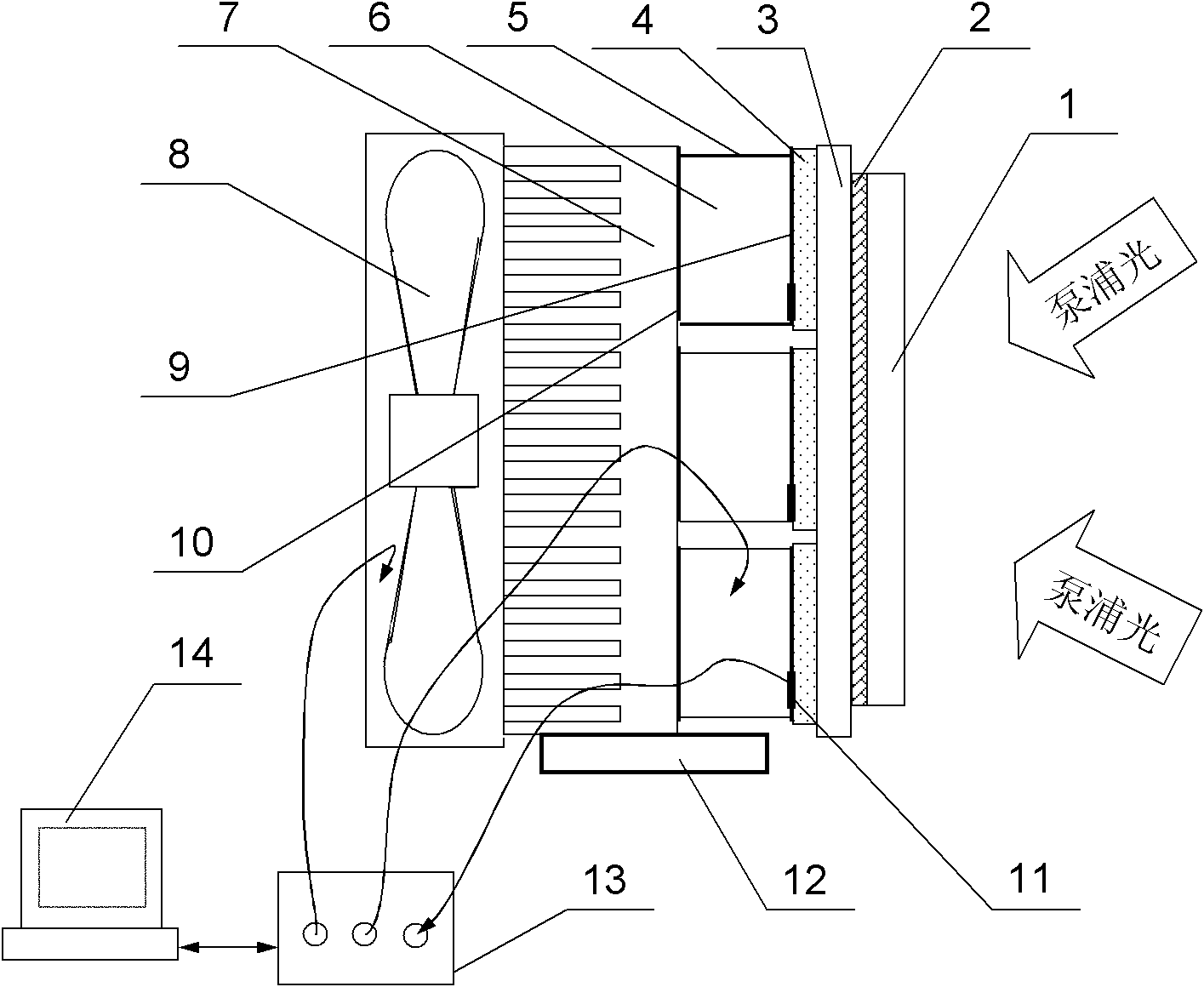

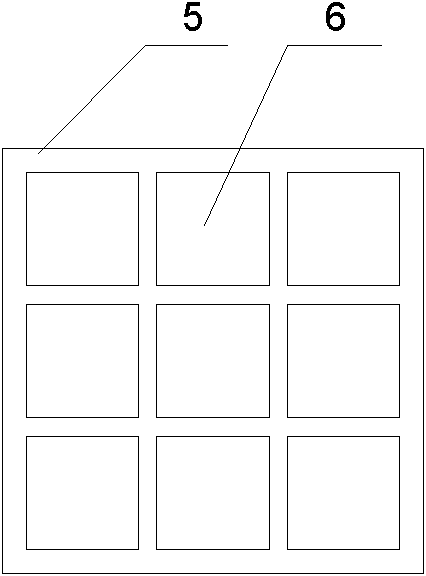

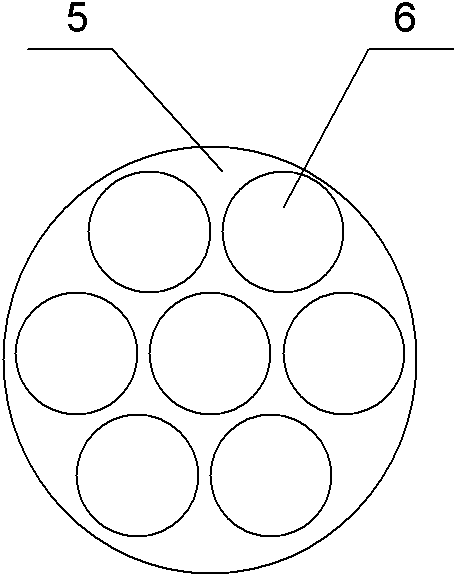

[0040] In this example, the whole process of the temperature control method of the present invention is simulated by using the finite element analysis software ANSYS. In the device for realizing the method, the specific parameters used are as follows: the laser medium 1 adopts a square sheet Nd with a thermal conductivity of 13W / (m K): YAG crystal, whose size is 30mm×30mm in length and width, and has a thickness of 1mm; the thickness of the welding layer 2 is 0.3mm; the heat sink 3 adopts a copper heat sink with a thermal conductivity of 221W / (m·K), the size, length and width are 30×30mm, and the thickness is 1mm; the thermal conductive adhesive 4 is thermal conductive silica gel, The radiator 7 is an aluminum heat sink, the fan 8 is a DC fan with a power of 24W, the temperature sensor 11 adopts a thermistor temperature sensor with a detection accuracy of 0.1 degrees, the closed-loop circuit control system 13 is a single-chip microcomputer controllable closed-loop circuit syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com