Method for preparing turkey red oil by using microstructure reactors

A technology of microstructure reactor and Turkish red oil, which is applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of low reaction safety performance, complicated preparation process, and low equipment utilization rate, and achieve the elimination of reaction Effects of hot spots, high sulfation levels, and fast stabilization times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

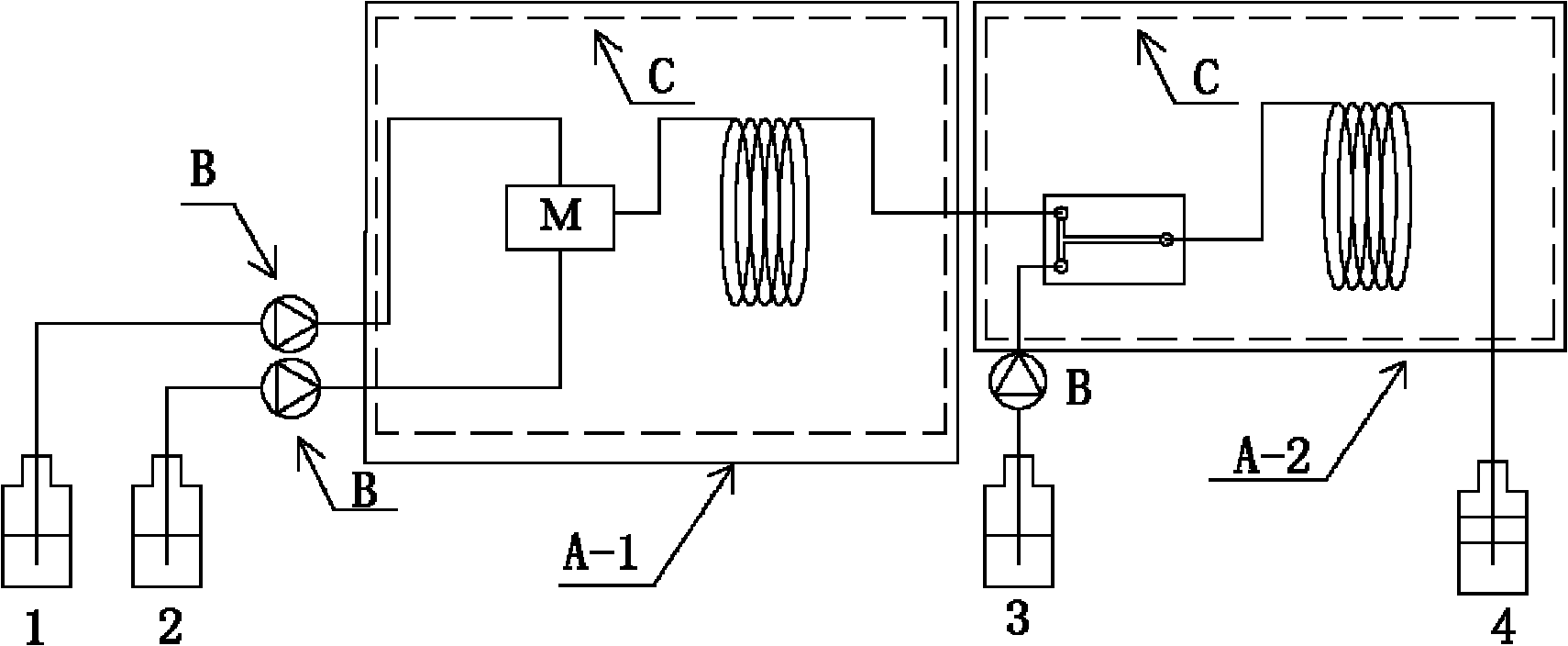

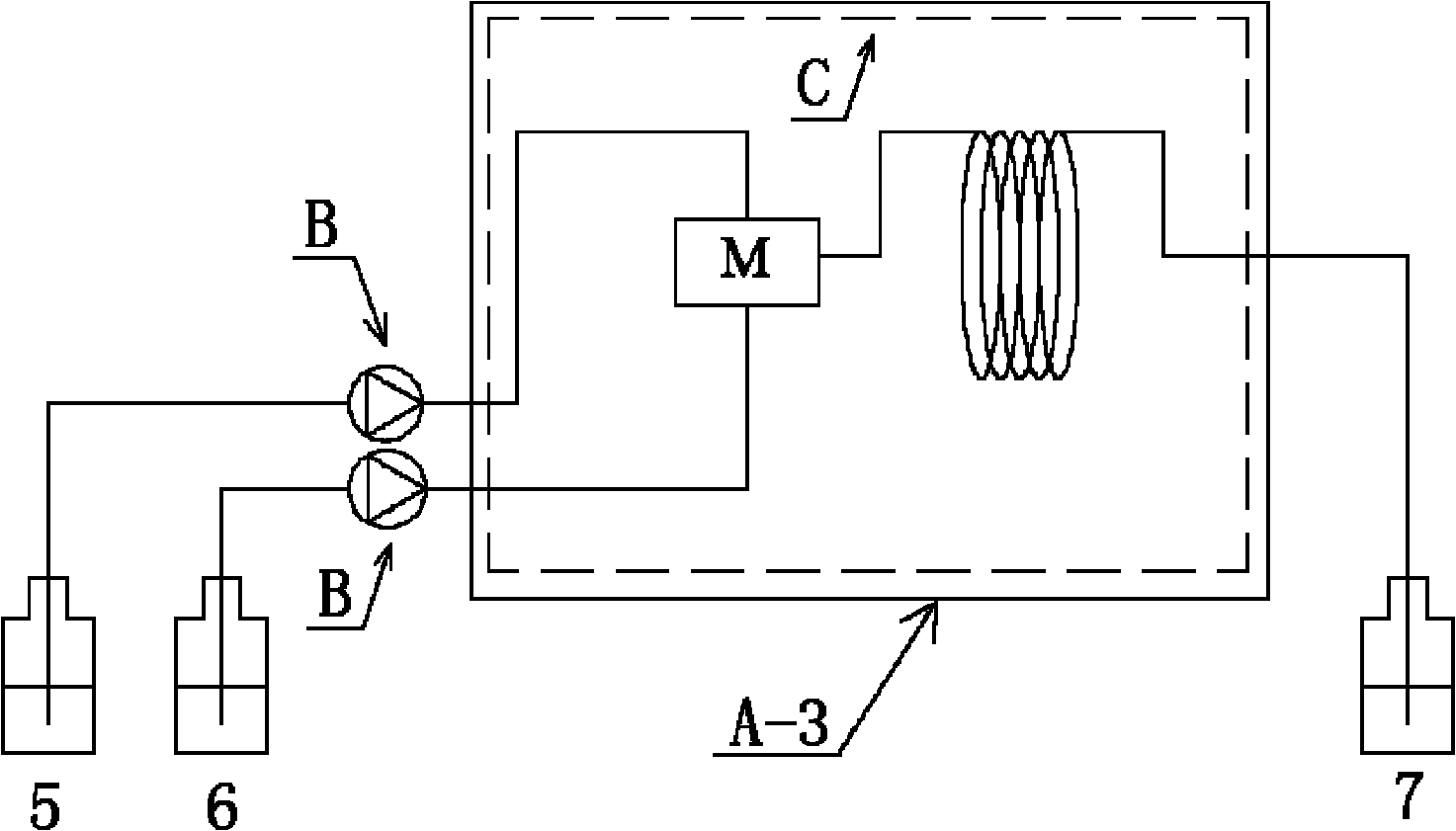

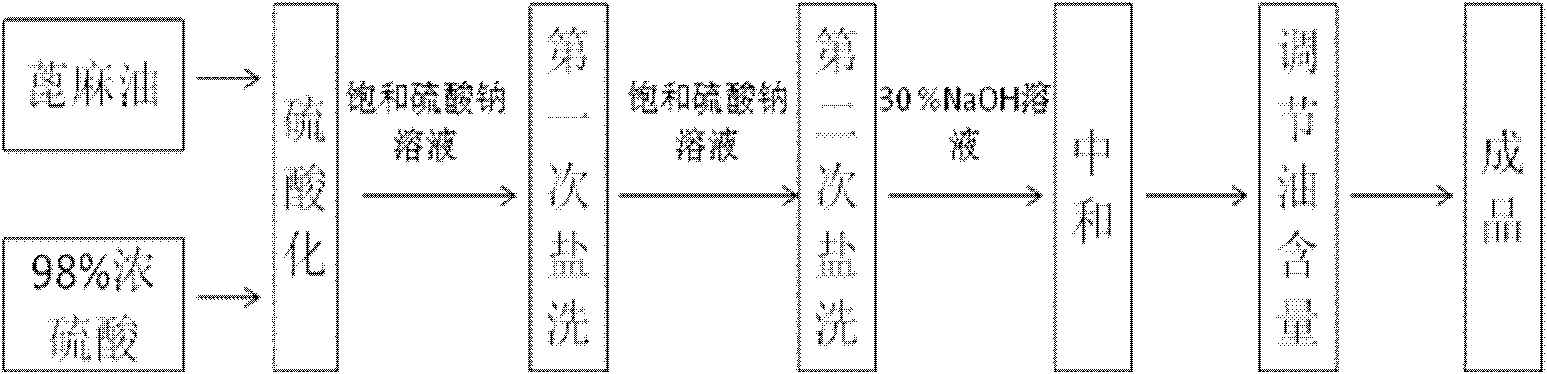

[0027] 98% concentrated sulfuric acid and castor oil were injected into the microstructure reactor A-1 with the temperature controlled at 40°C at a molar ratio of 4:1 through the high performance liquid chromatography pump, wherein the microstructure mixer was a heat exchange type microstructure reactor. Mixer (SIMHEX, IMM, Germany), its channel size is 25 * 25 * 20 (μ m), the microchannel reactor is the FEP tube of internal diameter 2mm, long 8000mm, after reacting 10min, the reaction product that obtains is mixed with saturated sodium sulfate The solution was pumped into the microstructure reactor A-2 for washing to remove excess concentrated sulfuric acid, wherein the microstructure mixer was a T-type mixer (mikroglas, Germany), the channel size was 200×25 (μm), and the washing temperature was controlled at 40°C , the microchannel reactor is a stainless steel tube with a length of 5000 mm and an inner diameter of 2 mm. The washing time is 200 s. The above salt washing is rep...

Embodiment 2

[0029] 95% concentrated sulfuric acid and castor oil were injected into the microstructure reactor A-1 with the temperature controlled at 40°C at a molar ratio of 4:1 through the high performance liquid chromatography pump, wherein the microstructure mixer was a heat exchange type microstructure reactor. Mixer (SIMHEX, IMM, Germany), its channel size is 25 * 25 * 20 (μm), the microchannel reactor is the FEP tube of inner diameter 2mm, long 8000mm, after reacting for 6.8min, the reaction product obtained is mixed with saturated chlorine The sodium chloride solution was pumped into the microstructure reactor A-2 for washing to remove excess concentrated sulfuric acid, wherein the microstructure reactor was a T-type mixer (mikroglas, Germany), the channel size was 200 × 25 (μm), and the washing temperature was controlled at At 20°C, the microchannel reactor is a stainless steel tube with a length of 500mm and an inner diameter of 2mm. The washing time is 20s, and the salt washing ...

Embodiment 3

[0031] 98% concentrated sulfuric acid and castor oil were injected into the microstructure reactor A-1 with a temperature control of 40°C at a molar ratio of 4:1 through a high performance liquid chromatography pump, wherein the microstructure mixer was a heat exchange type microstructure reactor. Mixer (SIMHEX, IMM, Germany), the channel size is 25 × 25 × 20 (μm), the microchannel reactor is a FEP tube with an inner diameter of 2mm, and the length is 200mm. After reacting for 0.5min, the reaction product obtained is mixed with saturated sulfuric acid The sodium solution was pumped into the microstructure reactor A-2 for washing to remove excess concentrated sulfuric acid, wherein the microstructure reactor was a T-type mixer (mikroglas, Germany), the channel size was 200×25 (μm), and the washing temperature was controlled at 20 ℃, the microchannel reactor is a stainless steel tube with a length of 500mm and an inner diameter of 2mm, the washing time is 20s, and the salt washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com