Flux-cored welding wire integrated forming unit, production method of flux-cored welding wire

A molding unit and flux-cored wire technology, applied in welding media, welding equipment, metal rolling racks, etc., can solve problems affecting filling rate and surface roughness stability, unstable motor speed, disappearing, etc., to eliminate Unstable influencing factors, improving product quality, and improving the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

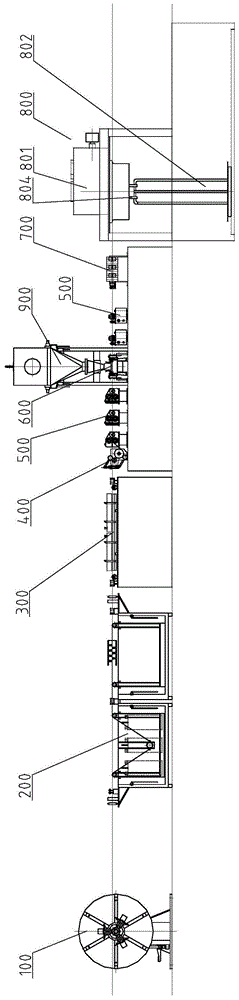

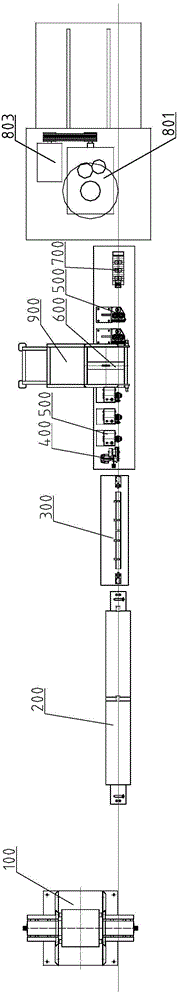

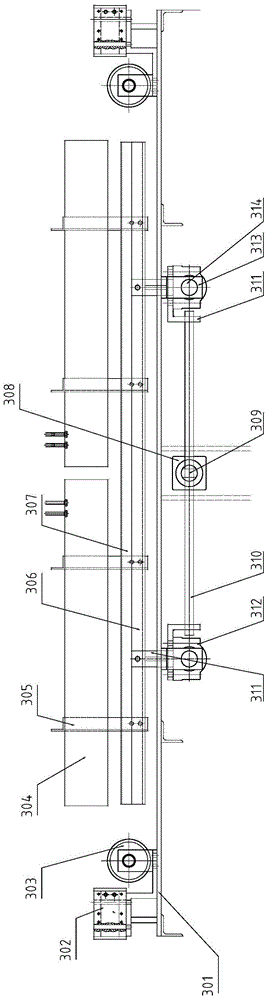

[0136] See Figures 15-16 , a flux-cored welding wire integrated molding machine set, including a tape unwinding machine 100, an ultrasonic cleaning device 200, a steel strip drying device 300, a molding machine, a speed-stabilizing traction device 801 at the exit of the molding machine, and a wire take-up device 802 arranged in sequence.

[0137] The above-mentioned molding machine is equipped with a steel strip speed measuring device 400, three horizontally installed passive rolling stands 500, a powder feeder 600 and its feeding system 900, three horizontally installed passive rolling stands 500 and rollers in order from the entrance to the exit. Die diameter reducing device 700.

[0138] The differences between this embodiment and Embodiment 1 are: 1) unwinding machine 100; 2) steel strip drying device 300; 3) steel strip speed measuring device 400; 4) passive rolling stand 500; 5) powder feeder 600 6) Stable speed traction device 801 and take-up device 802 at the exit of...

Embodiment 3

[0151] A method for producing flux-cored welding wire using the molding unit described in the above-mentioned embodiment 1 or embodiment 2, selecting a steel strip with a yield strength greater than 300Mpa, after the steel strip is released from the unwinding machine, it is cleaned by a cleaning device, and then Spray clean water on the running steel strip after cleaning to wash away the cleaning liquid on the surface of the steel strip, and then blow off most of the water on the surface of the steel strip through the air brush at the end of the ultrasonic cleaning tank. Then, the air brush at the front end of the steel strip drying device is used to flush the remaining water again, and then the infrared radiator irradiates the surface of the steel strip, and transfers the heat energy to the surface of the steel strip in the form of radiation, and bakes off the surface of the steel strip Remaining moisture that is difficult to remove by air blowing.

[0152] Use the steel belt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com