Process and technological equipment for continuously cracking and recycling waste organic glass

A plexiglass and waste technology, which is applied in the field of continuous waste plexiglass cracking and recycling process and its process equipment, can solve the problems of damaged cracking kettle, low labor efficiency, high labor intensity, etc., to increase the contact surface and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

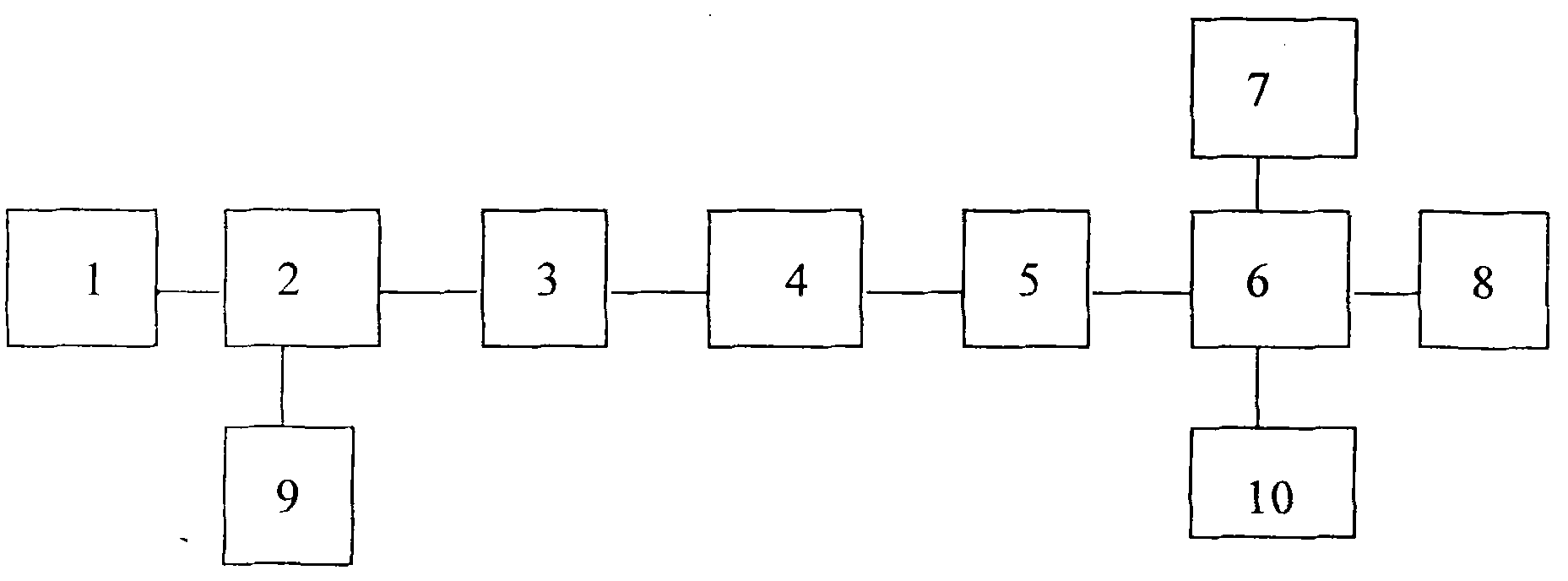

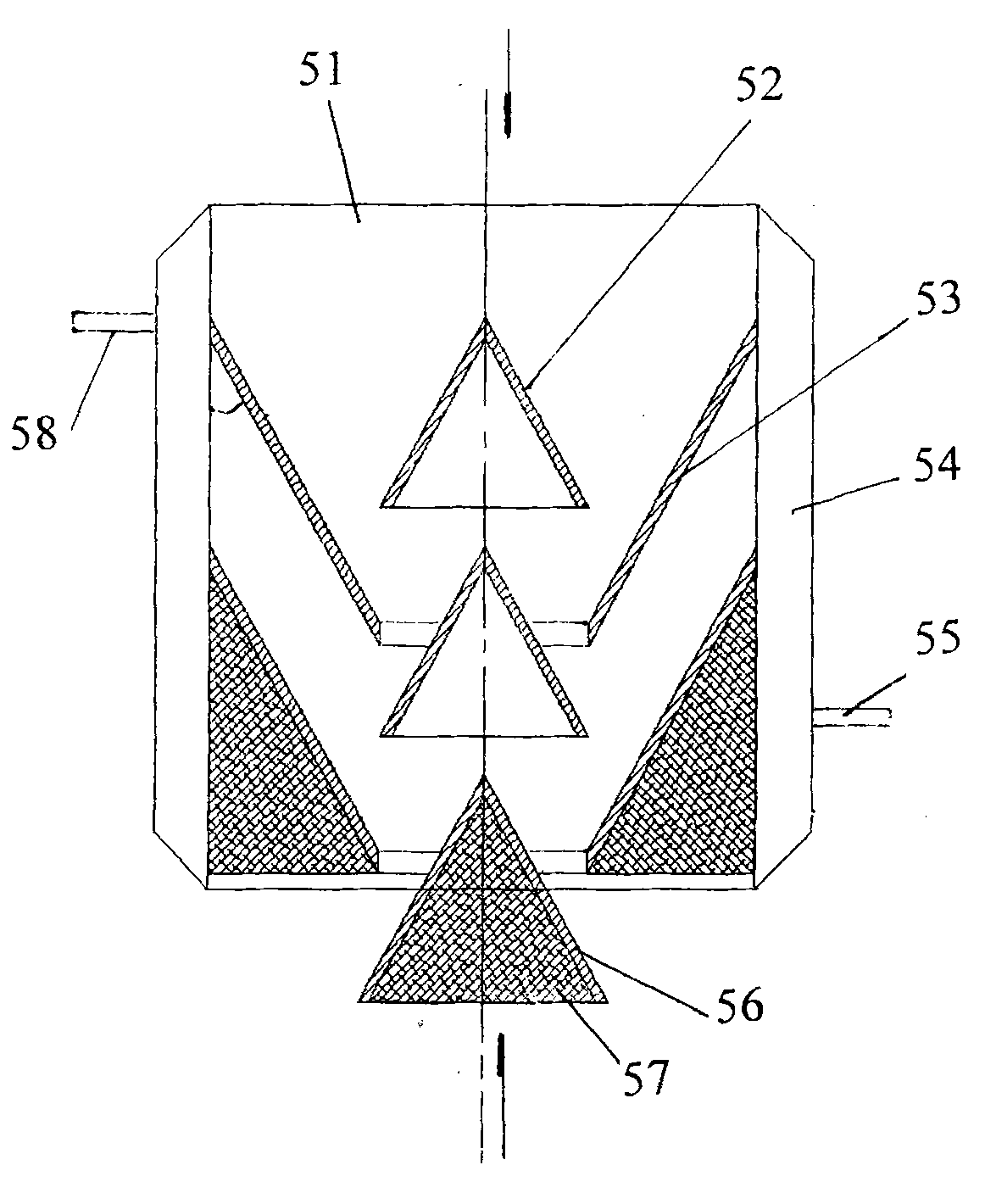

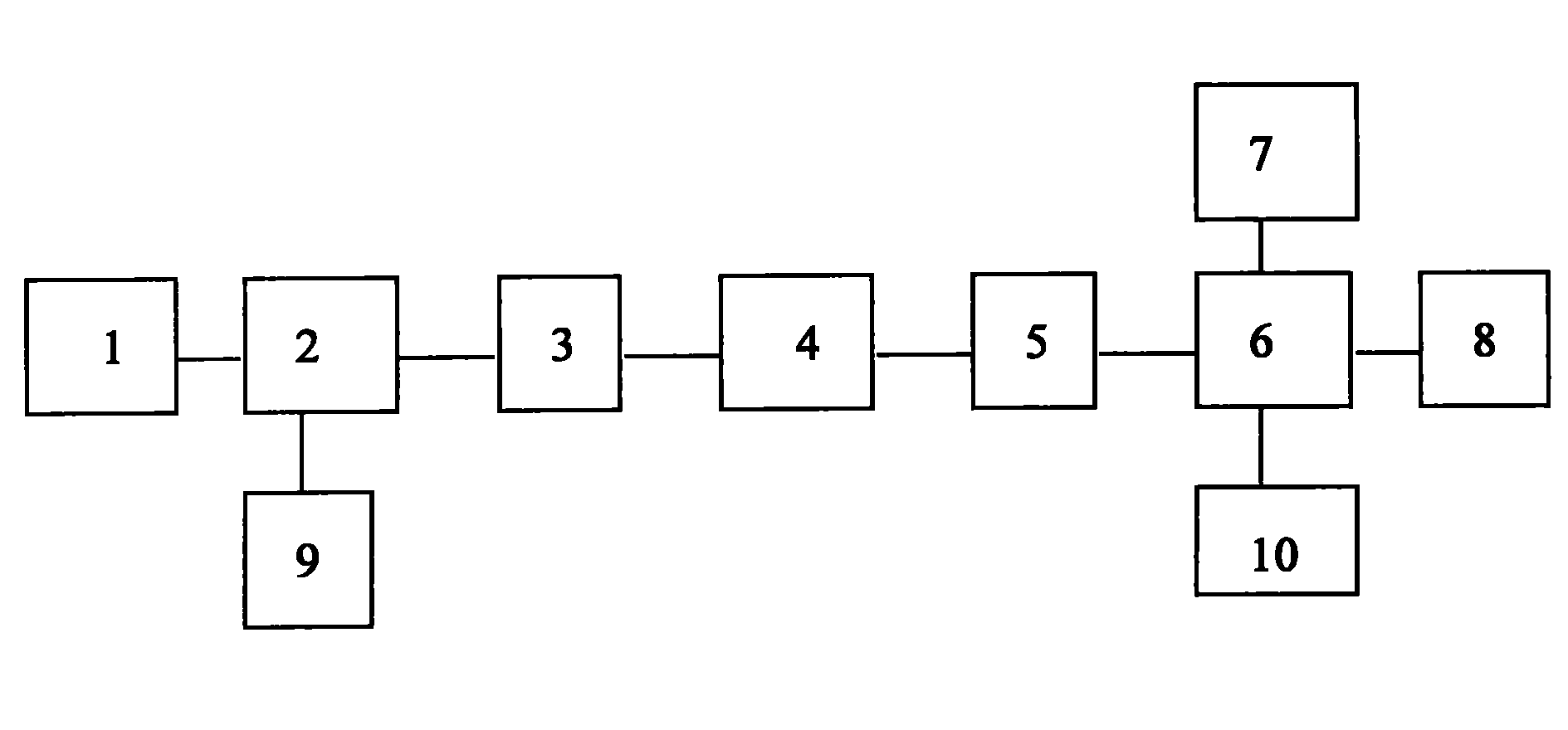

[0023] The waste plexiglass pellets are conveyed to the feed bin 2 through the screw feeder 1. After the feed bin is filled with pellets, the gas in the feed bin 2 is replaced, and nitrogen is filled after vacuuming, so that the pressure of the feed bin 2 is equal to that of the cracking kettle. The pressure in 6 is the same, add liquid molten salt into the cracking kettle 6, heat the cracking kettle 6 to make the temperature of the molten salt reach about 460°C, then open the lower slide valve of the material bin 2 and the vibrating feeder 4, waste organic glass The material particles are transported into the pyrolysis kettle 6 through the new heat-proof radiation feeder 5, and the waste organic glass particles are quickly gasified by the high-temperature molten salt in the pyrolysis kettle 6, and the gasified products are transported to the rectification system through the gas outlet pipe 8 for recovery; Endothermic process, so the temperature of the cracking kettle 6 is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com