Method for preparing water soluble graphene

A graphene and water-soluble technology, applied in the field of materials, can solve the problems of destroying the graphene structure and reducing the essential properties of graphene materials, and achieve good stability and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

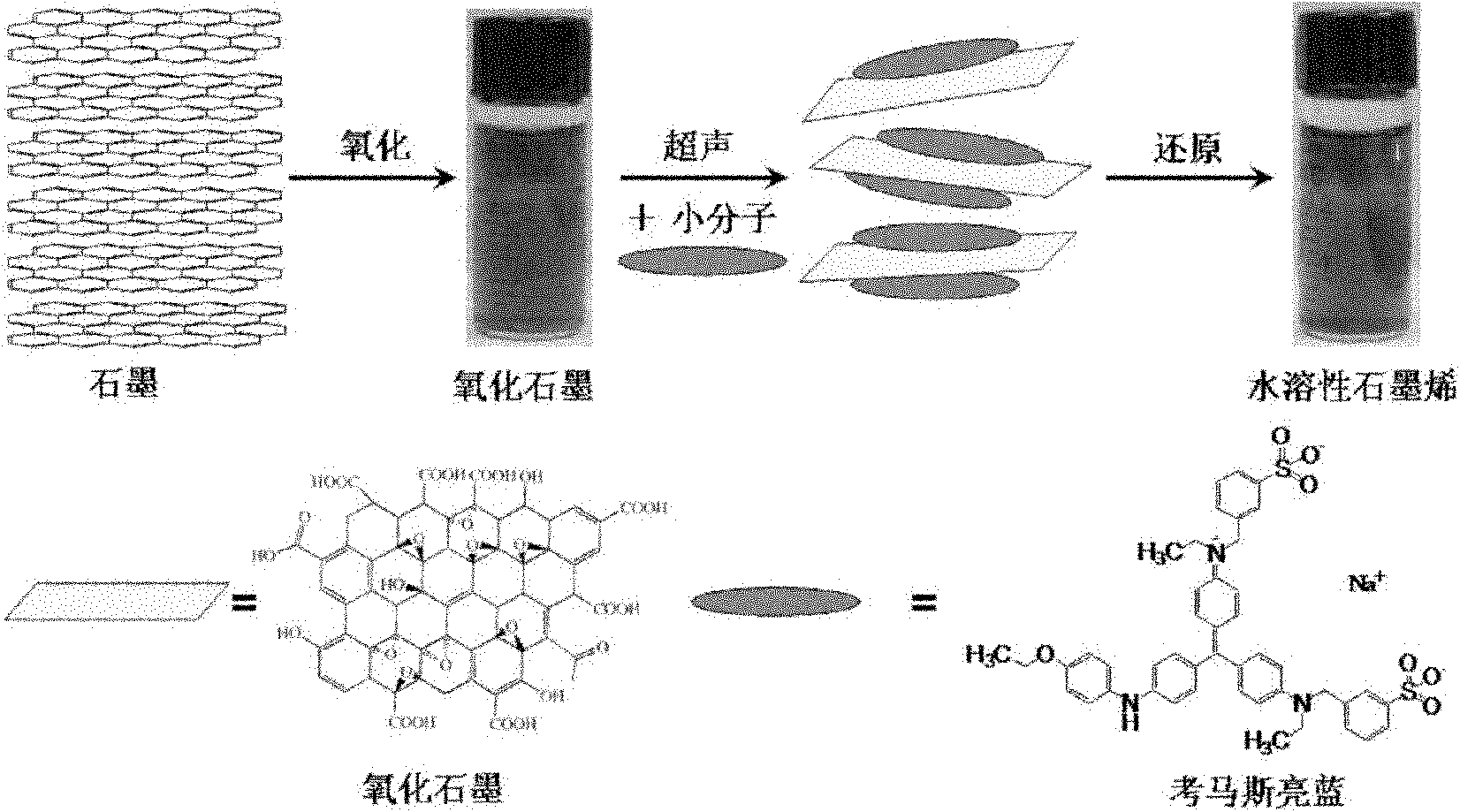

[0058] A kind of preparation method of water-soluble graphene, as attached figure 1 shown, including the following steps:

[0059] In a 1000mL flask, add 400mL of hydrochloric acid with a mass concentration of 5%, then add 10g of natural graphite powder, soak at 20°C for 24h, centrifuge, and wash the filter cake with distilled water 6 times, 100mL each time, and then dry it in an oven at 105°C for 48h , to obtain pretreated graphite powder. In a 1000mL flask, add 200mL of concentrated sulfuric acid with a mass concentration of 98%, then add 10g of pretreated graphite powder, cool to 0°C in an ice-salt bath, and slowly add 25g of KMnO 4 , keep the temperature in the flask at 20°C. After the addition, the temperature was raised to 30°C, and after 2 hours of reaction, the reactants in the flask were slowly poured into a 4000mL beaker, 1500mL of distilled water was added, and then 20mL of hydrogen peroxide (you can see that the solution turned bright yellow), centrifuged at 300r...

Embodiment 2

[0064] A kind of preparation method of water-soluble graphene, as attached figure 1 shown, including the following steps:

[0065] In a 1000mL flask, add 500mL of hydrochloric acid with a mass concentration of 5%, then add 10g of natural graphite powder, soak at 30°C for 48h, centrifuge, and wash the filter cake with distilled water 6 times, 100mL each time, and then dry it in an oven at 110°C for 24h , to obtain pretreated graphite powder. In a 1000mL flask, add 250mL of concentrated sulfuric acid with a mass concentration of 98%, then add 10g of pretreated graphite powder, cool to 0°C in an ice-salt bath, stir at 70rpm, and slowly add 30g of KMnO 4 , keep the temperature in the flask at 20°C. After the addition, the temperature was raised to 35°C, and after 3 hours of reaction, slowly pour the reactants in the flask into a 4000mL beaker, add 2000mL of distilled water, and then add 25mL of hydrogen peroxide (you can see that the solution turns bright yellow), and centrifuge...

Embodiment 3

[0070] A kind of preparation method of water-soluble graphene, as attached figure 1 shown, including the following steps:

[0071] In a 1000mL flask, add 600mL of hydrochloric acid with a mass concentration of 5%, then add 10g of natural graphite powder, soak at 40°C for 24h, centrifuge, and wash the filter cake with distilled water 6 times, 100mL each time, and then dry it in an oven at 115°C for 48h , to obtain pretreated graphite powder. In a 1000mL flask, add 200mL of concentrated sulfuric acid with a mass concentration of 98%, then add 10g of pretreated graphite powder, cool to 0°C in an ice-salt bath, stir at 80rpm, and slowly add 25g of KMnO 4, keep the temperature in the flask at 20°C. After the addition, the temperature was raised to 30°C, and after 2 hours of reaction, slowly pour the reactants in the flask into a 4000mL beaker, add 1500mL of distilled water, and then add 30mL of hydrogen peroxide (you can see that the solution turns bright yellow), and centrifuge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

| Solubility | aaaaa | aaaaa |

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com