Producing method and device of high purity ammonia

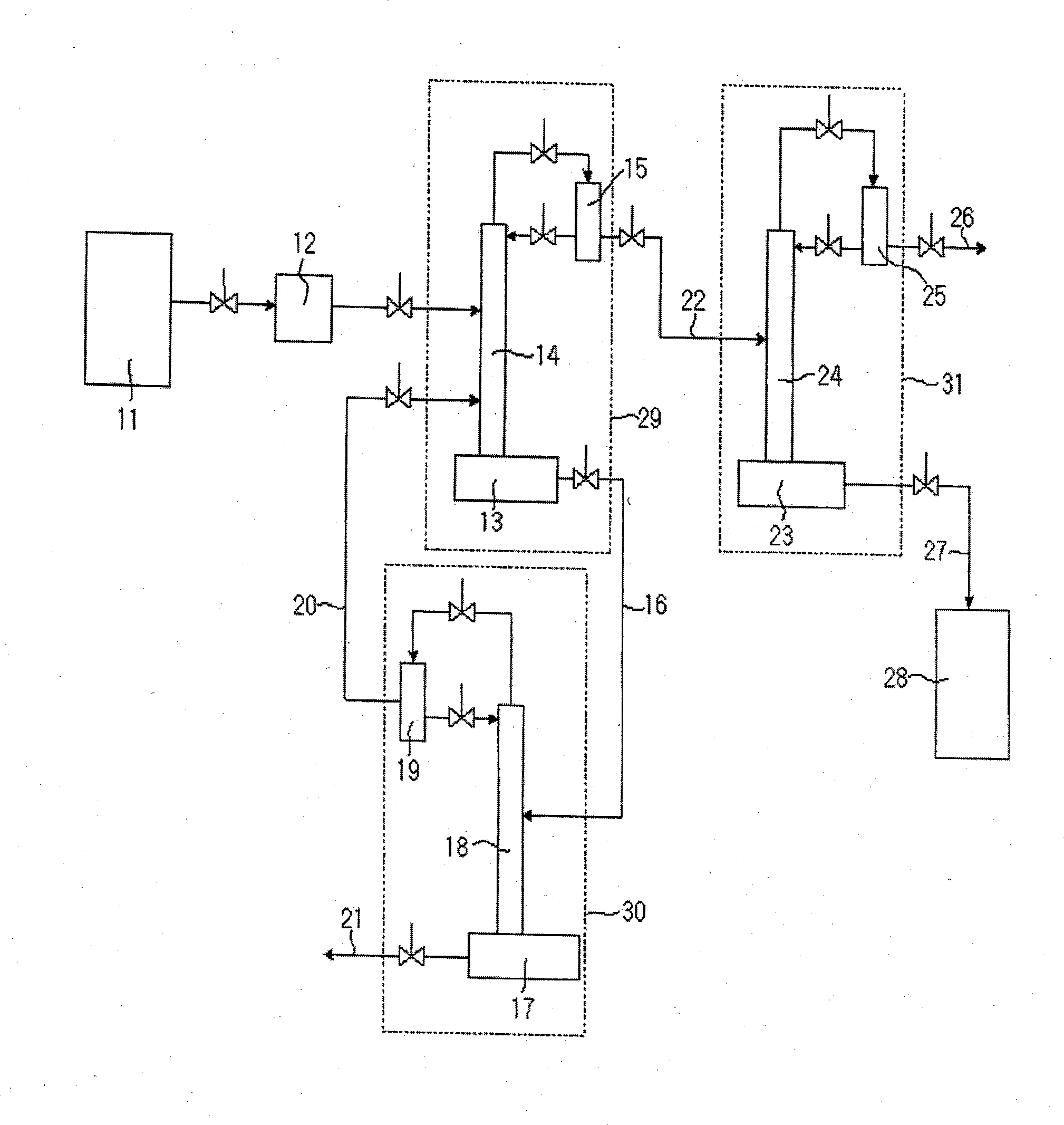

A manufacturing method and technology of a manufacturing device are applied in the field of high-purity ammonia manufacturing, and can solve the problems of troublesome replacement of filters, secondary pollution of heavy metals, and reduced productivity of filters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Embodiment 1 is the result of using the manufacturing device of high-purity liquid ammonia designed and manufactured by the present invention to carry out experiments. The raw material used in Example 1 was low-purity liquefied ammonia (purity about 99.5%), which was supplied to the second-stage distillation column via a vaporizer. At this time, the temperature of the gasifier is 60°C, and the pressure is maintained at about 8 atmospheres. The temperature of the reboiler of the second-stage distillation column was maintained at 29° C., the temperature of the upper part of the distillation column was maintained at 16° C., and the internal pressure was maintained at 7.5 atmospheres. At this time, the inflow flow rate is: deliver 50kg of liquid ammonia per hour, and the power of the reboiler must be 4.8kw. In the reboiler of the second-stage distillation column, water and heavy metals collected in the lower part due to the difference in volatilization point are fed into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com