Transparent thermal insulation material, manufacturing method thereof and transparent thermal insulation film

A technology of heat insulation materials and manufacturing methods, applied in the direction of coating, etc., can solve the problems of dark color of heat insulation film, insufficient infrared barrier performance, inability to achieve high heat insulation performance, etc., and achieve the effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

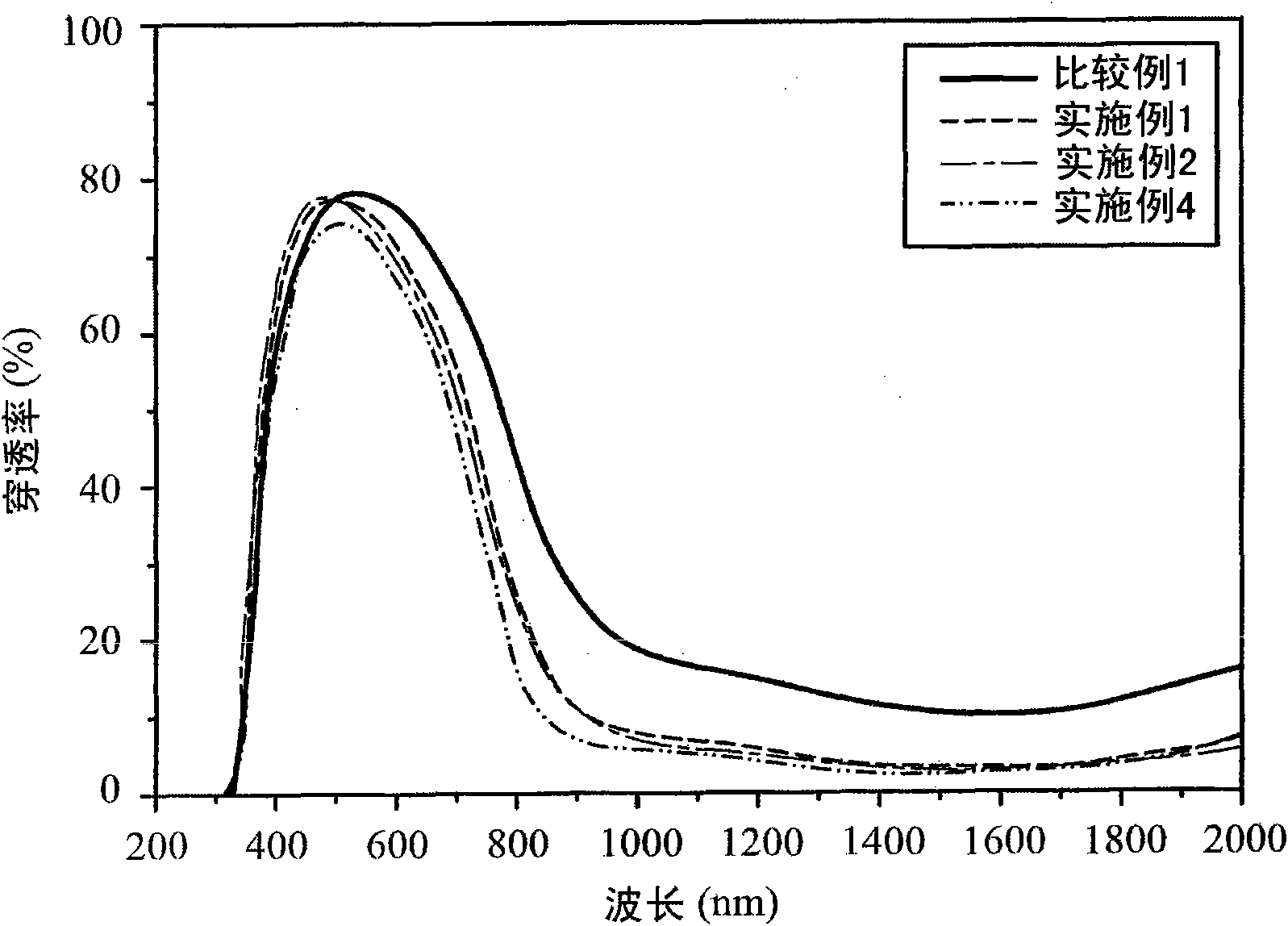

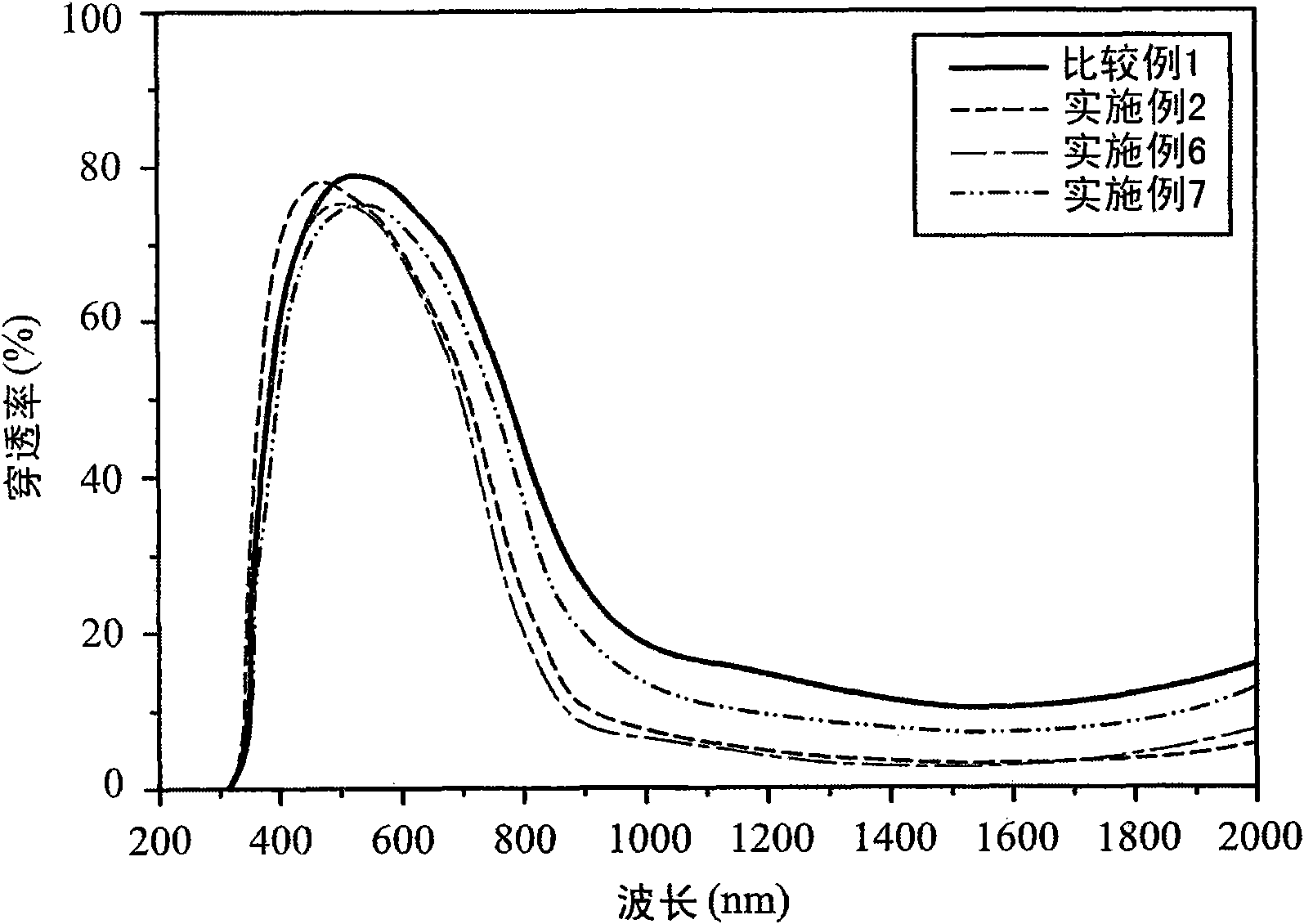

[0041] [Example 1] Preparation of a thermal insulation material with a molar ratio of Cs:W:Cl=0.33:1:0.03 and a transparent thermal insulation film made of this material

[0042] 10g of ammonium metatungstate (manufactured by SHOWA) was formulated into a 30wt% aqueous solution and stirred evenly to obtain transparent liquid A1. Get 0.07g ammonium chloride (produced by SHOWA), add transparent liquid A1, stir well, obtain transparent liquid A1'. Take 2.2g of cesium carbonate (manufactured by Alfa Aesar) to prepare a 50wt% aqueous solution, and stir evenly to obtain a transparent liquid B1. Then slowly drop the liquid B1 into the liquid A1' while maintaining the stirring of the liquid A1' to obtain the transparent mixed liquid C1. The mixed liquid was heated at 145°C to obtain a powdery initial product. The initial product was heated at 550° C. for 20 minutes under a reducing environment of 10 vol % hydrogen. The heat insulating material powder product P1 having a molar ratio ...

Embodiment 2

[0045] [Example 2] Preparation of a thermal insulation material with a molar ratio of Cs:W:Cl=0.33:1:0.05 and a transparent thermal insulation film made of this material

[0046] 10g of ammonium metatungstate was formulated into a 30wt% aqueous solution and stirred evenly to obtain transparent liquid A2. Get 0.11g ammonium chloride, add transparent liquid A2, stir, obtain transparent liquid A2'. Take 2.2g of cesium carbonate to prepare a 50wt% aqueous solution, and stir evenly to obtain a transparent liquid B2. Then slowly drop the liquid B2 into the liquid A2' while maintaining the stirring of the liquid A2' to obtain the transparent mixed liquid C2. The mixed liquid C2 was heated at 145°C to obtain a powdery initial product. The initial product was heated at 550° C. for 20 minutes under a reducing environment of 10 vol % hydrogen to obtain a thermal insulation material powder product P2 with a molar ratio of Cs:W:Cl=0.33:1:0.05.

[0047] The thermal insulation material po...

Embodiment 3

[0049] [Example 3] Preparation of a thermal insulation material with a molar ratio of Cs:W:Cl=0.33:1:0.20 and a transparent thermal insulation film made of this material

[0050] 10g of ammonium metatungstate was formulated into a 30wt% aqueous solution and stirred evenly to obtain transparent liquid A3. Get 0.44g ammonium chloride, add transparent liquid A3, stir, obtain transparent liquid A3 '. Take 2.2g of cesium carbonate to prepare a 50wt% aqueous solution, and stir evenly to obtain transparent liquid B3. Then slowly drop the liquid B3 into the liquid A3' while maintaining the stirring of the liquid A3' to obtain the transparent mixed liquid C3. The mixed liquid C3 was heated at 145°C to obtain a powdery initial product. The initial product was heated at 550° C. for 20 minutes under a reducing environment of 10 vol % hydrogen to obtain a thermal insulation material powder product P3 with a molar ratio of Cs:W:Cl=0.33:1:0.20.

[0051] The thermal insulation material pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com