Catalyst component and catalyst for olefin polymerization

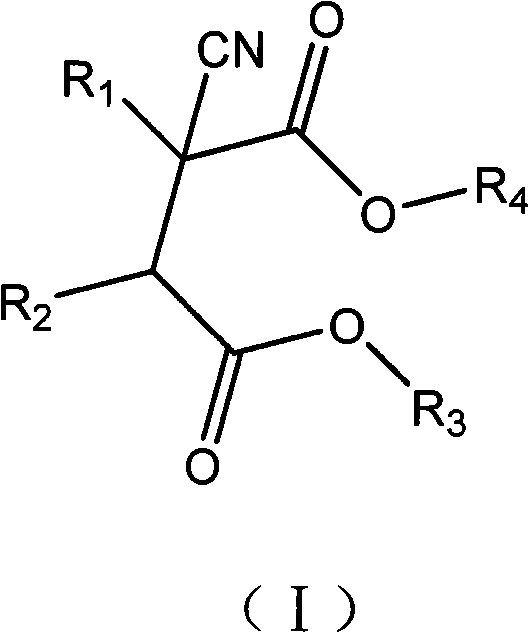

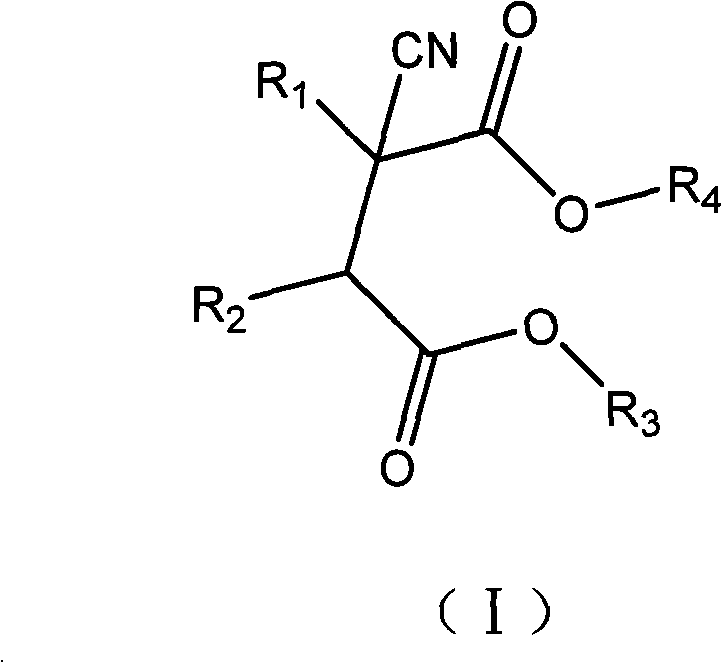

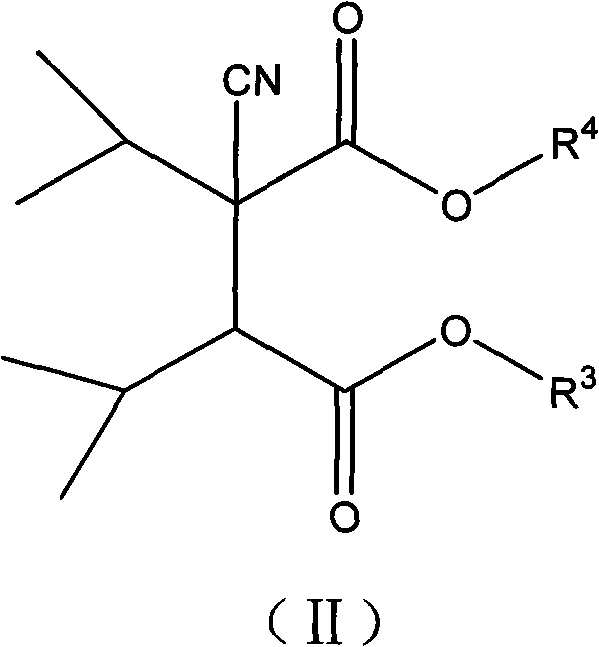

A technology of olefin polymerization and solid catalyst, which is applied in the application of catalysts in olefin polymerization and the application field of olefin homopolymerization and copolymerization, and can solve the problems of low catalytic activity, difficulty in industrial application of internal electron donor compound synthesis process, polymer Narrow relative molecular mass distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Preparation of catalyst solid components

[0058] In the reactor fully replaced by high-purity nitrogen, 4.8g of magnesium chloride, 95ml of toluene, 4ml of epichlorohydrin, and 12.5ml of tributyl phosphate (TBP) were sequentially added, and the temperature was raised to 50°C under stirring and maintained for 2.5 hours. After complete dissolution, 1.4 g of phthalic anhydride was added and maintained for 1 hour. Cool the solution to below -25°C and add TiCl dropwise within 1 hour 4 56ml, slowly warming up to 80°C, during the heating process, the solid matter is gradually precipitated, and the 2,3-diisopropyl-2-cyanobutanediol prepared according to the method described in the patent application specification of China Invention Patent Application No. 200910077779.6 is added Acetate diethyl ester 5mmol, maintain the temperature for 1 hour, after filtration, add toluene 70ml, wash twice to obtain a solid precipitate. Then add toluene 60ml, TiCl 4 40ml, heat up to 100°...

Embodiment 2

[0071] (1) The preparation of the catalyst solid component is the same as in Example 1, except that the 2,3-diisopropyl-2-cyano-succinic acid prepared by the method described in the patent application description of China Invention Patent Application No. 200910077779.6 - 1-isobutyl-4-ethyl ester (5 mmol) in place of diethyl 2,3-diisopropyl-2-cyanosuccinate (5 mmol).

[0072] (2) The propylene polymerization method is the same as that of Example 1, and the test results are shown in Table 1.

Embodiment 3

[0074] (1) preparation of catalyst solid component, with embodiment 2.

[0075] (2) Propylene polymerization

[0076] In a 5L autoclave, 5ml of a hexane solution of triethylaluminum (the concentration of triethylaluminum is 0.5mmol / ml), 1.25ml of cyclohexylmethyldimethoxysilane (CHMMS ) hexane solution (the concentration of CHMMS is 0.1mmol / ml), 10ml of anhydrous hexane and 10mg of the solid catalyst component obtained in Example 1 above. Close the autoclave, introduce 6 L of hydrogen gas (standard volume) and 2.3 L of liquid propylene, raise the temperature to 70° C., and polymerize for 1 hour. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com