UV (ultraviolet) roller-coating metal high-adhesion yellowing-resistant primer

A yellowing and metal-resistant technology, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of fading, difficult repair, poor paint adhesion, etc., to achieve good adhesion and easy construction , good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

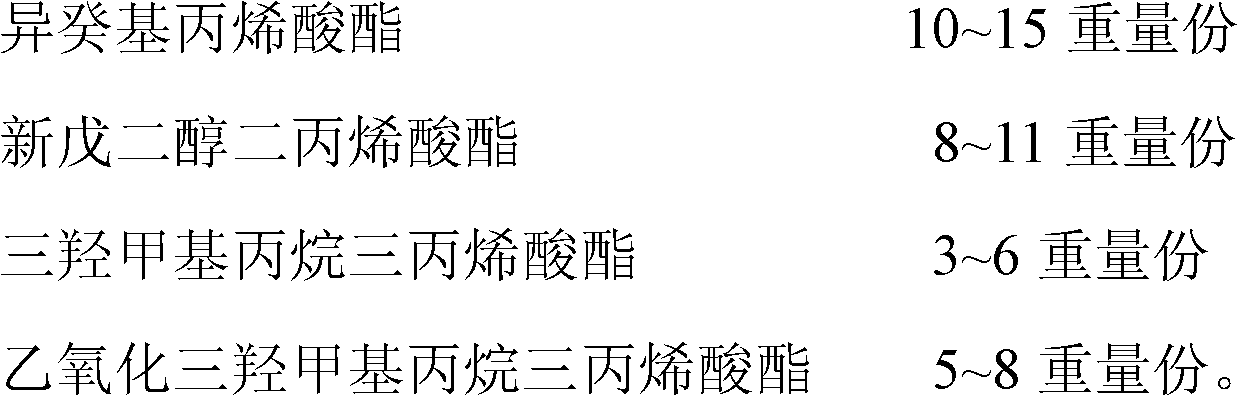

Method used

Image

Examples

Embodiment 1

[0033] Take 14 kg of functional monomer isodecyl acrylate (ISODA), 9 kg of neopentyl glycol diacrylate (NPGDA), 5 kg of trimethylolpropane triacrylate (TMPTA), ethoxylated trimethylolpropane Triacrylate (TMP3EOTA) 5 kg, polyurethane acrylate (GM-509) 17 kg, epoxy acrylic resin (4219) 21 kg, defoamer (BYK066) 0.4 kg, leveling agent (BYK310) 0.2 kg, functional Additive (AFCONA-S527) 0.7 kg, silane coupling agent (KH-550) 4 kg, filler (TP-1250) 14 kg, anti-settling agent (229) 0.2 kg, mix and stir, after fully dispersed, add photoinitiator Agent (RUNTECURE1103) 9.5 kg, stir well and disperse evenly without lumps.

Embodiment 2

[0035] Take functional monomer isodecyl acrylate (ISODA) 10 kg, neopentyl glycol diacrylate (NPGDA) 11 kg, trimethylolpropane triacrylate (TMPTA) 3 kg, ethoxylated trimethylolpropane Triacrylate (TMP3EOTA) 7.5 kg, polyurethane acrylate (GM-509) 19 kg, epoxy acrylic resin (4219) 25 kg, defoamer (BYK066) 0.3 kg, leveling agent (BYK310) 0.3 kg, functional Additive (AFCONA-S527) 0.5 kg, silane coupling agent (KH-550) 2 kg, filler (TP-1250) 10 kg, anti-settling agent (229) 0.4 kg, mix and stir, after fully dispersed, add light trigger Agent (RUNTECURE1103) 11 kg, stir well and disperse evenly without lumps.

Embodiment 3

[0037] Take 24 kg of functional monomer isodecyl acrylate (ISODA), 16 kg of neopentyl glycol diacrylate (NPGDA), 12 kg of polyurethane acrylate (GM-509), 19 kg of epoxy acrylic resin (4219), Defoamer (BYK066) 0.3 kg, leveling agent (BYK310) 0.2 kg, functional additive (AFCONA-S527) 1 kg, silane coupling agent (KH-550) 2 kg, filler (TP-1250) 13.3 kg , 0.2 kg of anti-sedimentation agent (229), mix and stir, after fully dispersed, add 12 kg of photoinitiator (RUNTECURE 1103), stir well and disperse evenly without lumps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com