Method for preparing selenium-enriched yeasts by using Candida utilis

A technology of Candida utilis and selenium-enriched yeast, applied in the direction of microorganism-based methods, biochemical equipment and methods, and adding compounds to stimulate growth, etc., can solve the problem of high industrial production cost and low production cost Se-enriched yeast preparation method, low biomass of selenium-enriched yeast, etc., to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1.5 Preparation of medium

[0031] 1) Incline medium

[0032] Take 200g of peeled potatoes, cut into small pieces, add 1L of distilled water. Boil on low heat for 45-60 minutes, filter with gauze, then make up the lost water to 1L, and add sucrose: 20g; agar powder: 20g; yeast powder: 2g; peptone: 2g. Dispense it into test tubes while hot, the filling amount is 1 / 3 of the length of the test tube, and sterilize at 121°C for 20 minutes after stoppering. Before the culture medium is solidified, it is placed on a 15° slope, solidified and cultured at a constant temperature of 37°C for 24 hours to identify sterility, and stored in a 4°C refrigerator for later use.

[0033] 2) Natural medium (PS4), seed medium

[0034] Take 200g of peeled potatoes, cut into small pieces, add 1L of distilled water. Boil on low heat for 45-60 minutes, filter with gauze, then make up the lost water to 1L, and add 40g of sucrose at the same time, sterilize at 121°C for 20min, and store in a r...

Embodiment 1

[0040] The determination of embodiment 1 bacterial classification and substratum

[0041] 1. Recovery of strains

[0042] Brewer's yeast (Saccharomyces cerevisiae) and Candida utilis (Candidautilis) were respectively inoculated on the slant medium with an inoculation loop under sterile conditions, cultured at 28-30°C for 24 hours, and the strains were revived for two generations.

[0043] 2. Yeast seed culture

[0044] Fill the seed culture medium in a 250ml Erlenmeyer flask (50ml liquid volume), inoculate the revived strains into the seed culture medium respectively, and cultivate them at 150r / min at 28-30°C for 24h as seeds.

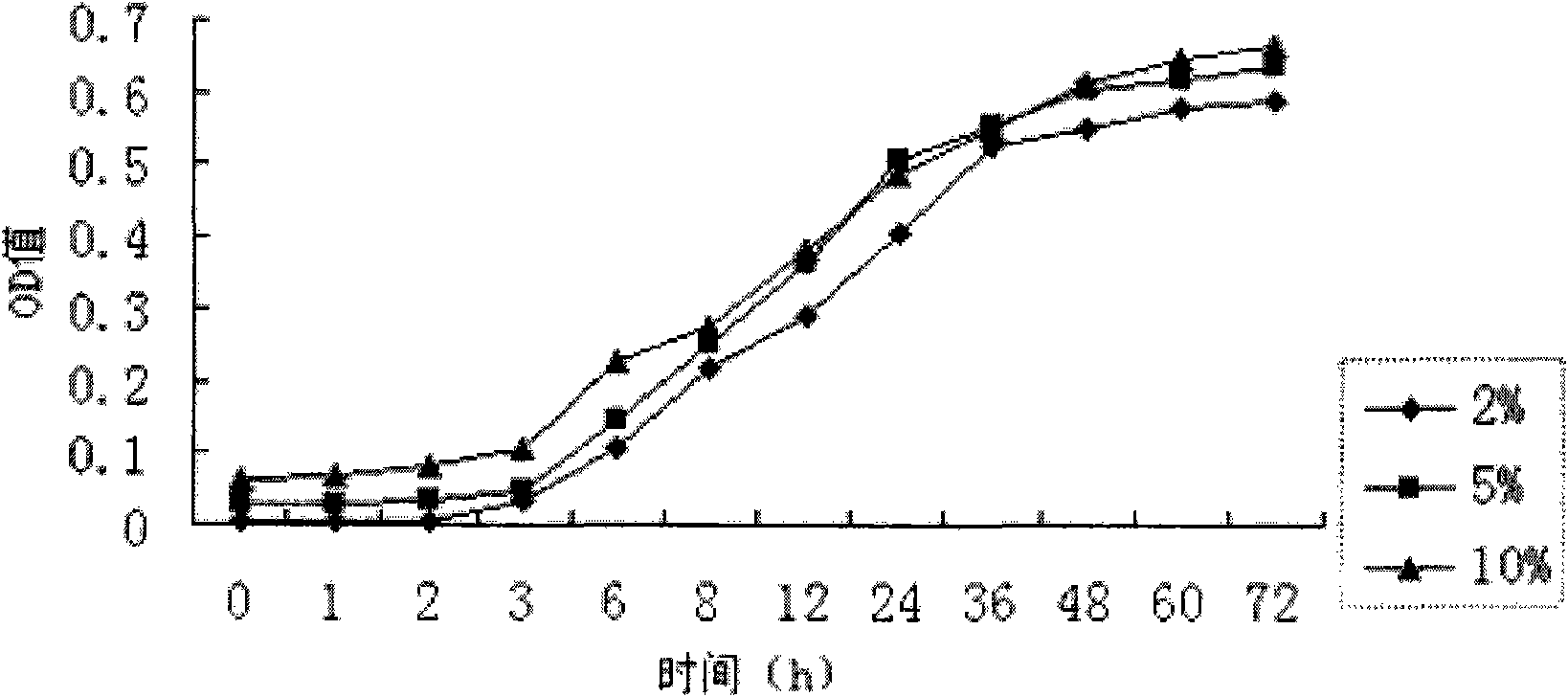

[0045] 3. Fermentation culture

[0046] 50ml of PS4, YPG and YPS liquid medium were filled in a 250ml Erlenmeyer flask respectively, and the two kinds of yeast seeds were inserted into different mediums with 10% inoculation amount, and cultured at 150r / min and 28-30°C for 72h. Harvest the bacterial liquid, centrifuge (5000r / min, 10min), discard the ...

Embodiment 2

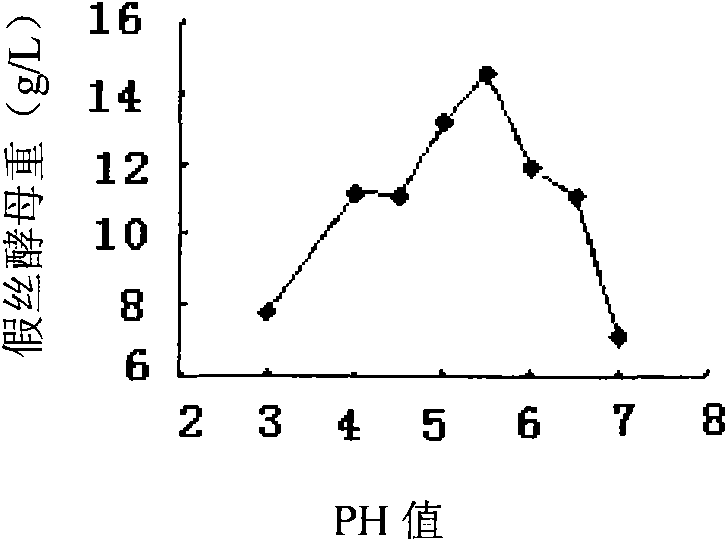

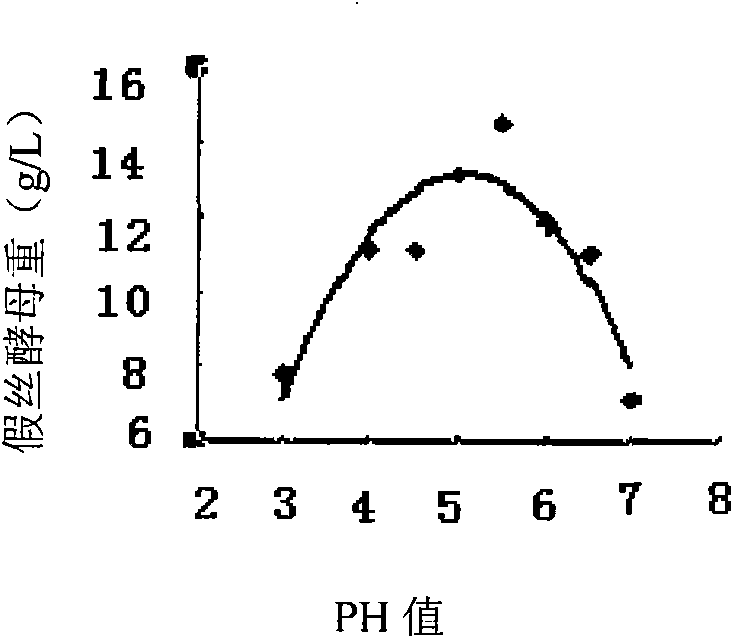

[0054] The influence of embodiment 2pH on the growth of Candida utilis

[0055] 1. Recovery of strains

[0056] Under sterile conditions, Candida utilis was inoculated on the slant medium with an inoculation loop, cultured at 28-30°C for 24 hours, and the strains were revived for two generations.

[0057] 2. Yeast seed culture

[0058] Put the seed culture medium in a 250ml Erlenmeyer flask (the volume of liquid is 50ml), inoculate the revived strains into the seed culture medium, and cultivate them at 150r / min at 28-30°C for 24h to serve as seeds.

[0059] 3. Fermentation culture

[0060] 50ml YPS liquid culture medium is packed in the Erlenmeyer flask of 250ml, inserts Candida utilis seed in culture medium with 10% inoculum size, adjusts pH value to be respectively 4,4.5,5,5.5,6,6.5, 7. Cultivate at 150r / min, 28-30°C for 72h. Harvest the bacterial liquid, centrifuge (5000r / min, 10min), discard the supernatant to harvest the bacterial cells, dry the bacterial cells at 65-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com