Structure of redox flow battery

A technology of liquid flow batteries and electric stacks, which is applied to the parts of fuel cells, fuel cells, battery electrodes, etc., can solve problems such as bipolar plate collapse, uneven electrode frame levels, and external leakage, and achieve convenient and fast assembly. The effect of simple and reasonable structure and low additional cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

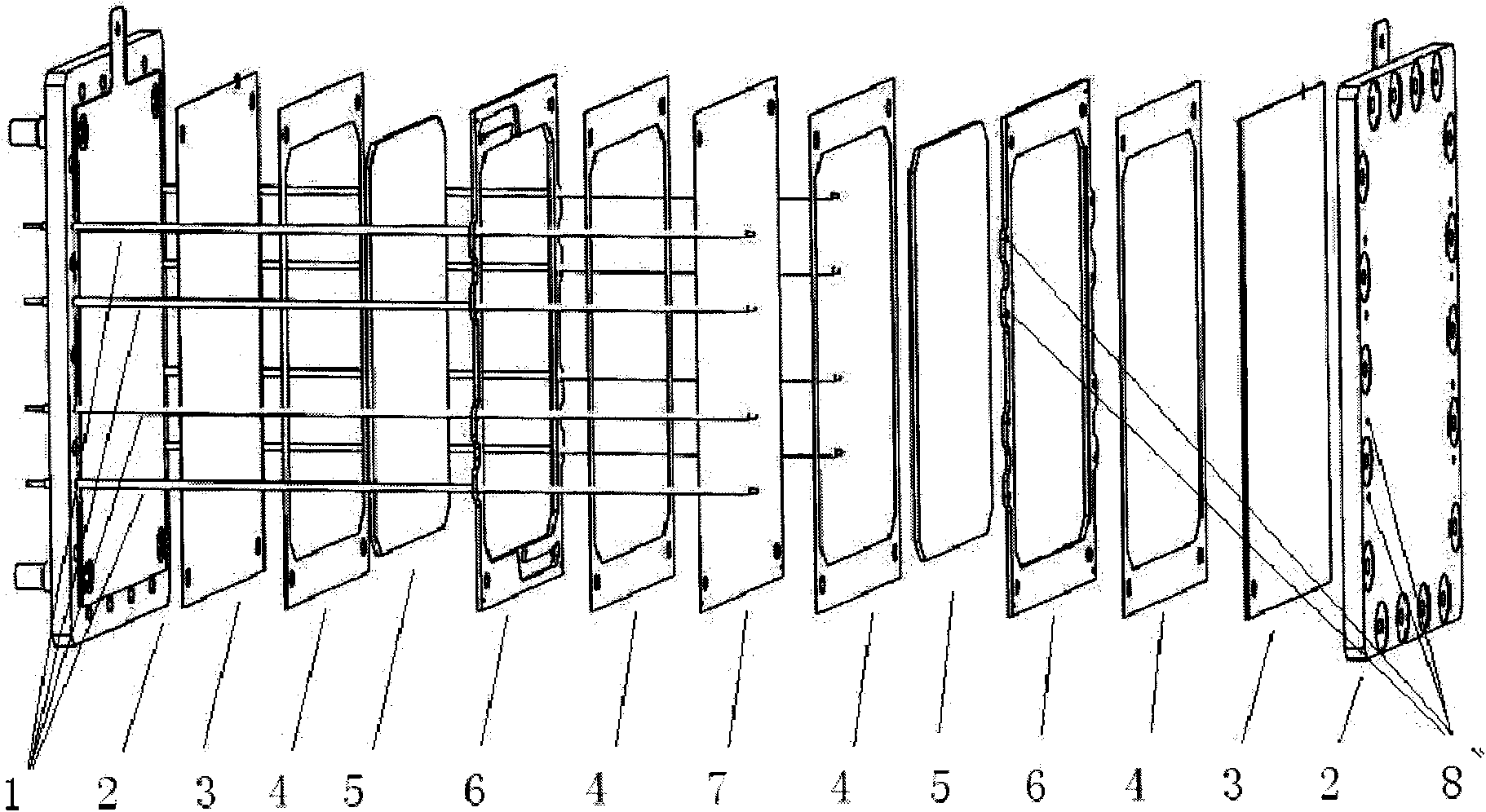

[0016] Battery structure such as figure 1 As shown, four rods used to limit the misalignment of the electrode frame pass through the end plate and the electrode frame, and are located on the long side of the electrode frame. The rod for limiting the dislocation of the electrode frame is composed of a Φ4 stainless steel rod covered with a Φ6×1 nylon tube, and the corresponding hole for restricting the dislocation of the electrode frame is Φ6.5.

[0017] Electrode area: 225cm2, number of single cells: 13.

[0018] After 2000 hours of continuous operation, the electrode frame has no obvious misalignment. The battery efficiency is not attenuated and remains at 86-89%, 90.5-92.4%, and the energy efficiency is greater than 80%

Embodiment 2

[0020] Battery structure such as figure 1 As shown, 6 rods used to limit the misalignment of the electrode frame pass through the end plate and the electrode frame, of which 4 are on the long side of the electrode frame and 2 are on the short side. The rod for restricting the dislocation of the electrode frame is made of Φ6×1 stainless steel tube, and the corresponding hole for restricting the dislocation of the electrode frame is Φ6.5.

[0021] The electrode area: 460cm2, the number of single cells: 20.

[0022] After 1500 hours of continuous operation, there is no obvious misalignment of the electrode frame. The battery efficiency is not attenuated, and remains at 85-89%, 90.2-91.0%, and the energy efficiency is greater than 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com