Full-automatic vacuum low-temperature fruit and vegetable fast maturing device

A vacuum low temperature, fully automatic technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of low efficiency, high labor intensity, low output, etc., achieve high quality, reduce labor intensity, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

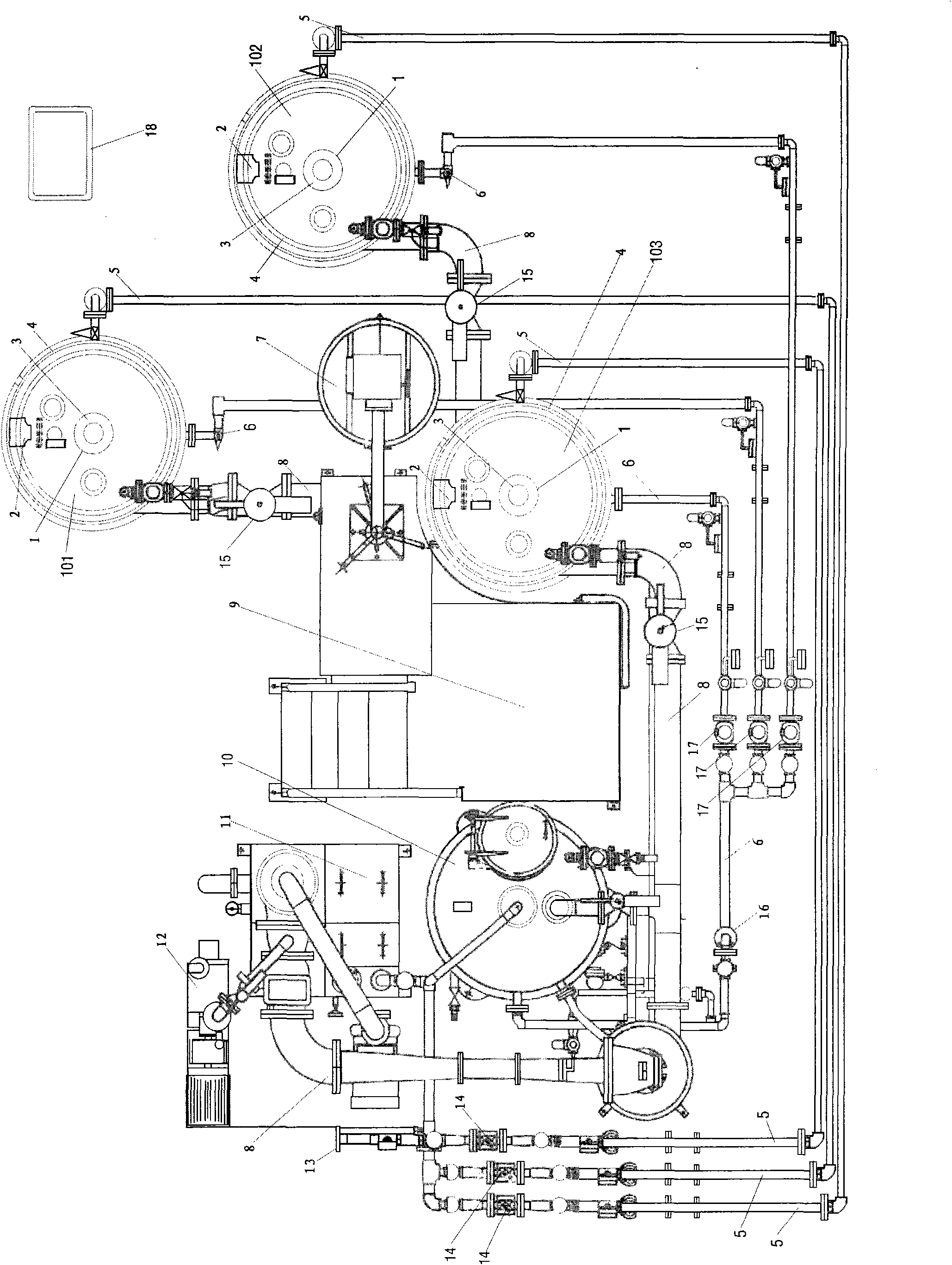

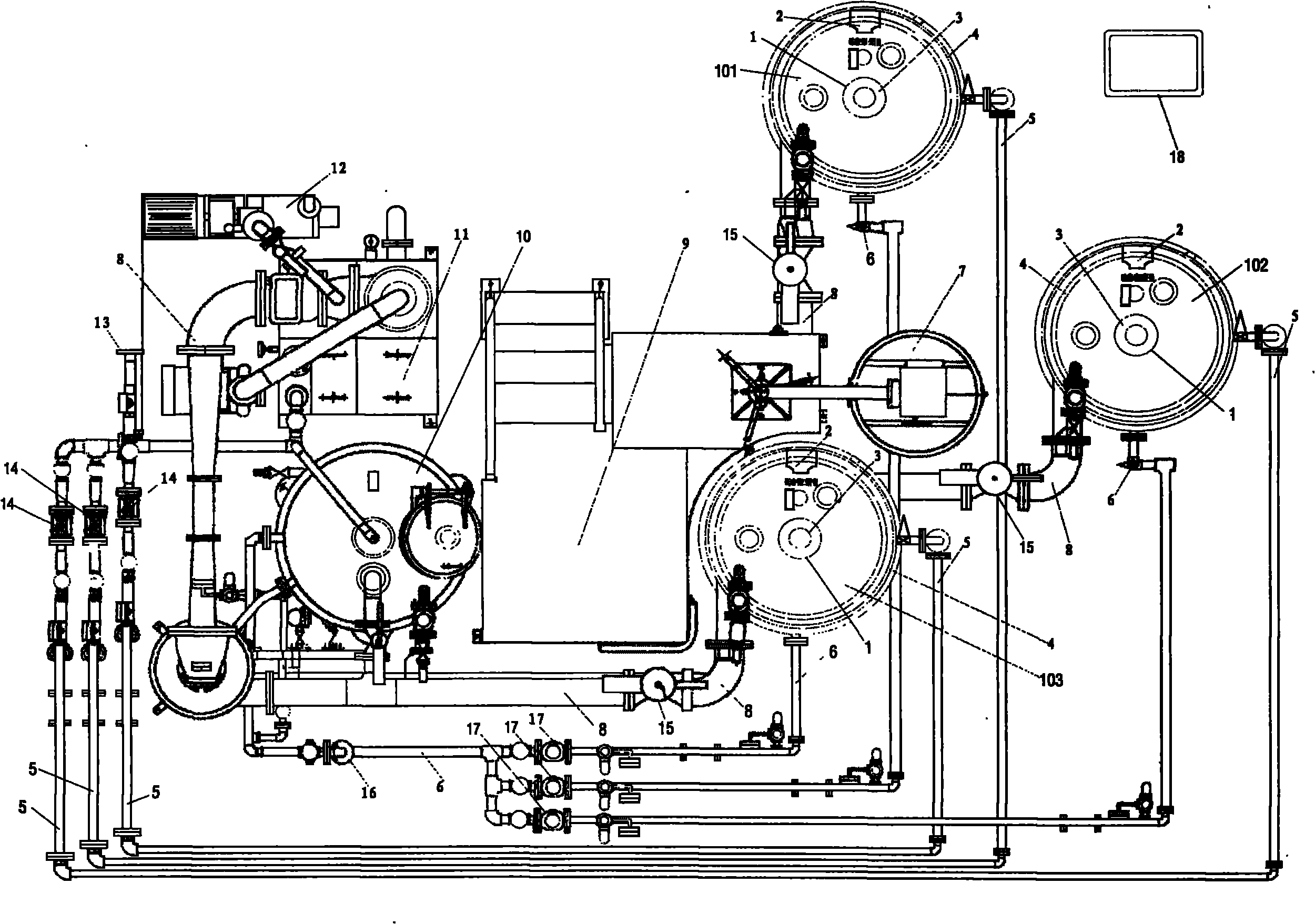

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

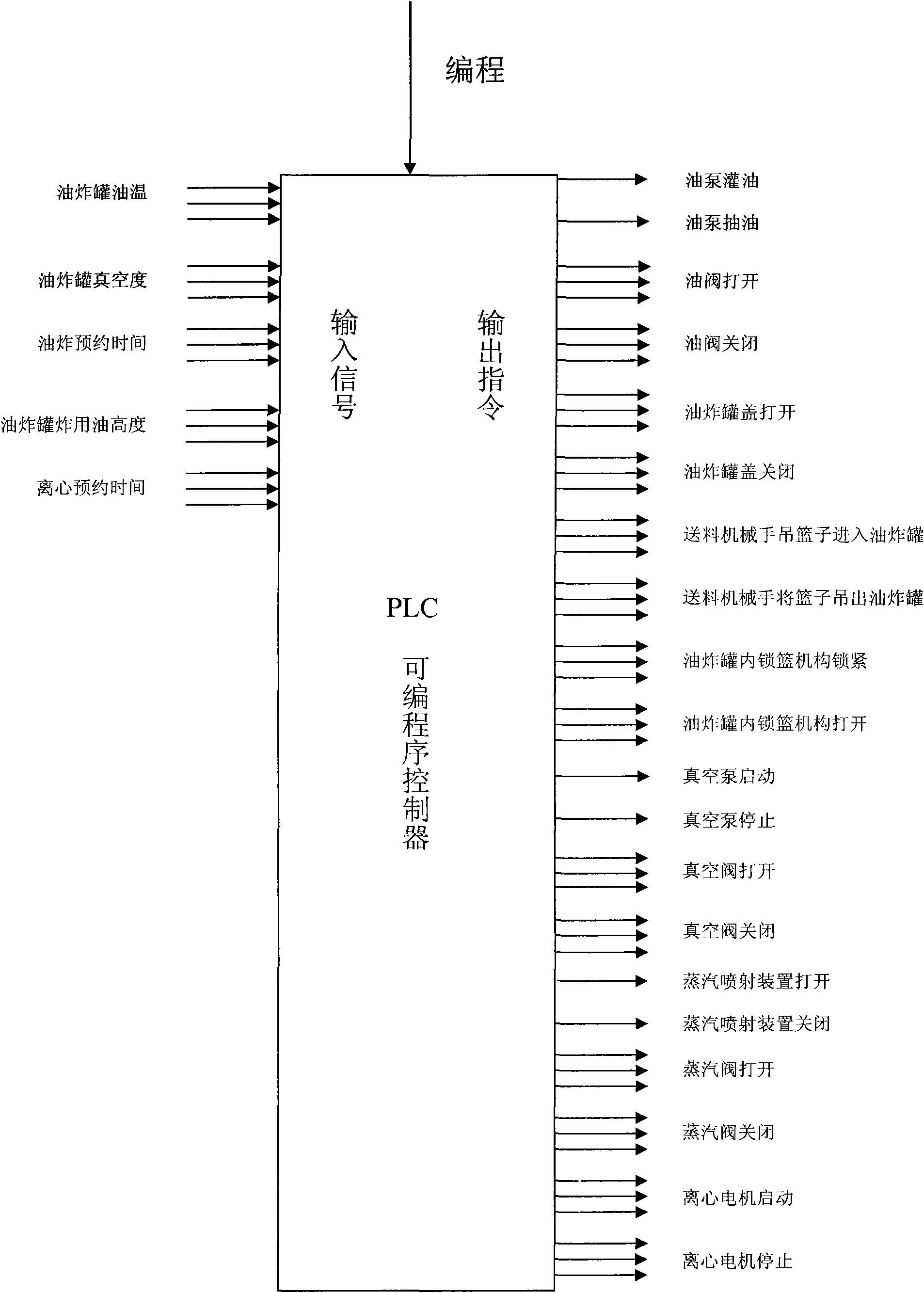

[0015] exist figure 1 Among them, the fully automatic vacuum low-temperature fruit and vegetable quick-cooking device of the present invention includes 3 vacuum frying tanks 101, 102 and 103, an oil storage tank 10, an oil pump 16, an oil valve (solenoid valve) 17, an oil pipe 6, a vacuum pump 12, and a vacuum pipe 8 , vacuum valve (solenoid valve) 15, steam inlet and outlet 13, steam injection device 11, steam pipe 5, steam valve (solenoid valve) 14, centrifugal motor and its rotating shaft 3, working platform 9, feeding manipulator 7 and programmable control system 18 . The structures and performances of the three frying tanks are the same, they are respectively connected to the oil storage tank 10 through the oil pipe 6, the oil valve 17, and the oil pump 16, and share one oil storage tank; the function of the oil pump 16 and the oil pipe 6 is to store oil The fry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com