Load type nickel base doped catalyst for biomass tar splitting and preparation method thereof

A nickel-based catalyst, tar cracking technology, applied in the direction of physical/chemical process catalysts, naphtha catalytic reforming, chemical instruments and methods, etc., can solve the problems of reduced activity of nickel-based catalysts, shortened catalyst life, reduced catalyst activity, etc. , to achieve low production cost, enhanced anti-carbon deposition and anti-high temperature sintering ability, and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

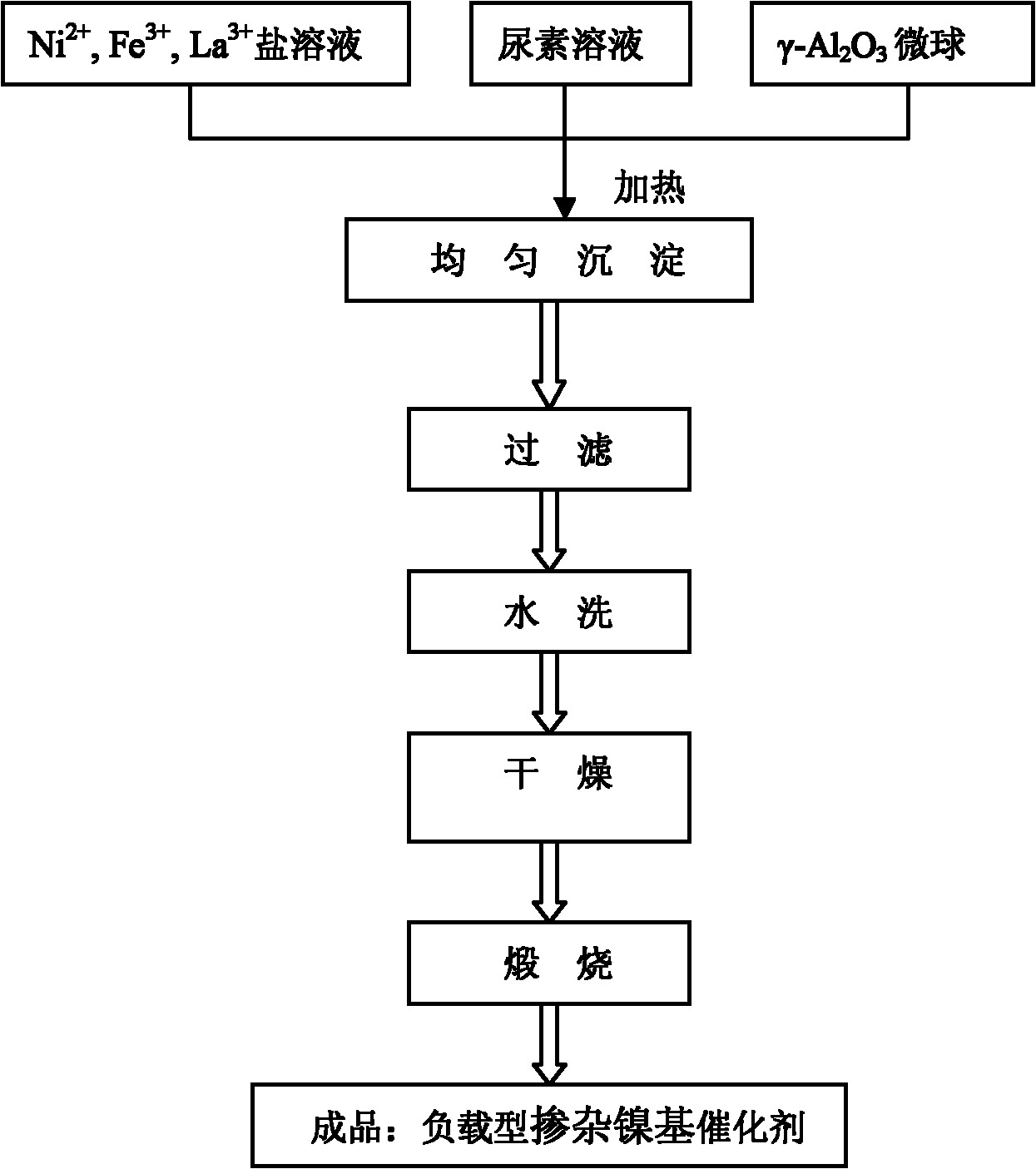

[0028] One of the preparations of supported doped nickel-based catalysts for biomass tar cracking. The preparation method consists of the following steps:

[0029] (1) Preparation of three metal salt solutions and uniform precipitant: the analytically pure 0.025molNi(NO 3 ) 2 ·6H 2 O, 0.01mol La(NO 3 ) 3 ·6H 2 O, 0.014mol Fe(NO 3 ) 3 ·9H 2 O and 0.20molCO(NH 2 ) 2 Dissolve in deionized water and stir it magnetically to make it evenly mixed to obtain a mixed solution of uniform concentration;

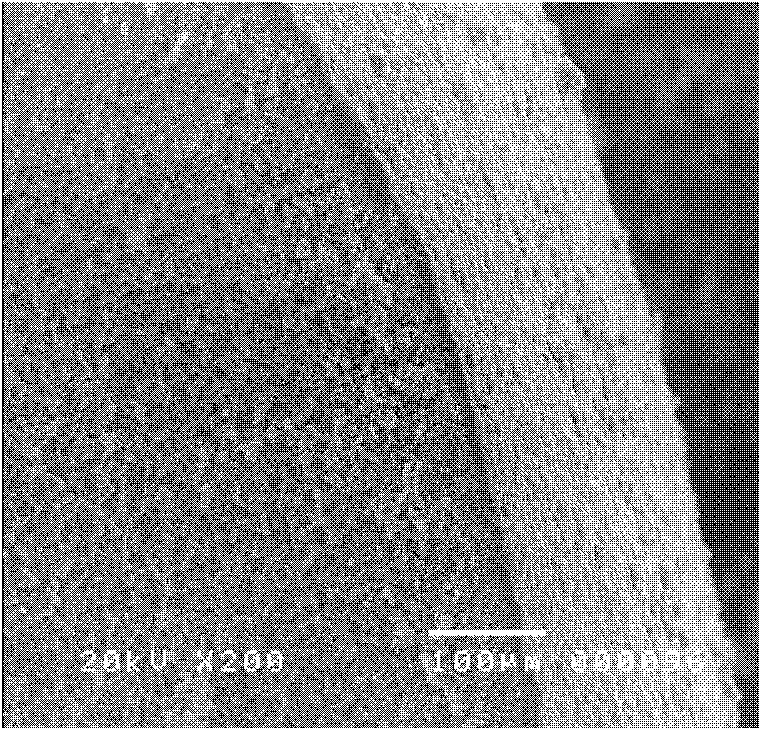

[0030] (2) Sedimentation: transfer the uniform mixed solution prepared in step (1) to a solution containing 8 grams of γ-Al 2 O 3 Carrier (spherical, particle size 2 ~ 4mm, purity> 99%) in a glass container, sealed, oil bath or electric heating to 115 ℃ and maintained for 2.5 hours, the precursor precipitate gradually deposited on the γ-Al 2 O 3 On the carrier, a tan sphere is obtained.

[0031] (3) Filtration and drying: The product of step (2) is suction filtered, washed with water to neutrali...

Embodiment 2

[0035] The second preparation of a supported doped nickel-based catalyst for biomass tar cracking, the preparation method consists of the following steps:

[0036] (1) Preparation of three metal salt solutions and uniform precipitant: the analytically pure 0.035molNi(NO 3 ) 2 ·6H 2 O, 0.005mol La(NO 3 ) 3 ·6H 2 O, 0.015mol Fe(NO 3 ) 3 ·9H 2 O and 0.20molCO(NH 2 ) 2 Dissolve in deionized water and stir it magnetically to make it evenly mixed to obtain a mixed solution of uniform concentration;

[0037] (2) Sedimentation: transfer the uniform mixed solution prepared in step (1) to a solution containing 8 grams of γ-Al 2 O 3 Carrier (spherical, particle size 2 ~ 4mm, purity> 99%) in a glass container, sealed, oil bath or electric heating to 115 ℃ and maintained for 2.5 hours, the precursor precipitate gradually deposited on the γ-Al 2 O 3 On the carrier, a tan sphere is obtained.

[0038] (3) Filtration and drying: The product of step (2) is suction filtered, washed with water to neutral...

Embodiment 3

[0042] The third preparation of a supported doped nickel-based catalyst for biomass tar cracking, the preparation method consists of the following steps:

[0043] (1) Preparation of three metal salt solutions and uniform precipitation agent: the analytically pure 0.03molNi(NO 3 ) 2 ·6H 2 O, 0.008mol La(NO 3 ) 3 ·6H 2 O, 0.016mol Fe(NO 3 ) 3 ·9H 2 O and 0.20molCO(NH 2 ) 2 Dissolve in deionized water and stir it magnetically to make it evenly mixed to obtain a mixed solution of uniform concentration;

[0044] (2) Sedimentation: transfer the uniform mixed solution prepared in step (1) to a solution containing 8 grams of γ-Al 2 O 3 Carrier (spherical, particle size 2 ~ 4mm, purity> 99%) in a glass container, sealed, oil bath or electric heating to 115 ℃ and maintained for 2.5 hours, the precursor precipitate gradually deposited on the γ-Al 2 O 3 On the carrier, a tan sphere is obtained.

[0045] (3) Filtration and drying: The product of step (2) is suction filtered, washed with water to n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com