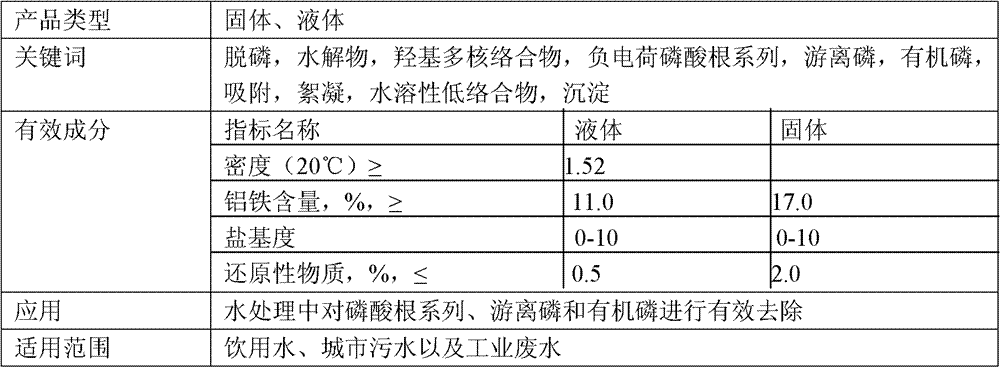

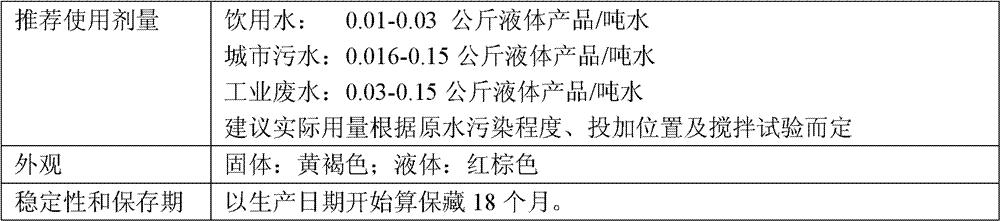

Efficient dephosphorization agent for waste water treatment

A high-efficiency dephosphorization agent and wastewater treatment technology, which is applied in the fields of flocculation/sedimentation water/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Influence, reduce the difficulty of processing, the effect of stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take aluminum sulfate 22.5%, iron sulfate 27.5%, sodium hypochlorite 17.5%, water 32.5%.

[0034] Add tap water to the reaction kettle according to the formula, turn on electric stirring, heat to 40°C, add solid aluminum sulfate and ferric sulfate, stir and dissolve completely, add sodium hypochlorite in several times to carry out polymerization reaction, after 4 hours of reaction, then heat up to 80°C Stable aging for 12 hours, filtered with 400-mesh polyester cloth to obtain a transparent liquid product.

Embodiment 2

[0036] Take aluminum sulfate 20%, iron sulfate 30%, sodium hypochlorite 20%, water 30%.

[0037] Add tap water to the reaction kettle according to the formula, turn on electric stirring, heat to 45°C, add solid aluminum sulfate and ferric sulfate, stir to dissolve completely, add sodium hypochlorite in several times to carry out polymerization reaction, react for 4 hours, and then heat up to 85°C Stable aging for 12 hours, filtered with 400-mesh polyester cloth to obtain a transparent liquid product. The liquid product is dried in a dryer and then crushed and sieved to obtain a solid granular high-efficiency dephosphorization agent. Dosing point during wastewater treatment: the outlet of the aeration tank; dosing method: first dilute to 20% concentration of diluent, so that the agent is evenly dispersed, fully reacted with water, stirred evenly and then added to the wastewater.

[0038] Dosage (mg / L)

Embodiment 3

[0040] Take aluminum sulfate 25%, iron sulfate 25%, sodium hypochlorite 15%, water 35%.

[0041] Add tap water to the reaction kettle according to the formula, turn on electric stirring, heat to 50°C, add solid aluminum sulfate and iron sulfate, stir and dissolve completely, add sodium hypochlorite in several times to carry out polymerization reaction, after reacting for 6 hours, then heat up to 85°C Steady aging for 8 hours, filtered with 400-mesh polyester cloth to obtain a transparent liquid product. Dosing point during wastewater treatment: the outlet of the aeration tank; dosing method: first dilute to 20% concentration of diluent, so that the agent is evenly dispersed, fully reacted with water, stirred evenly and then added to the wastewater.

[0042] Dosage (mg / L)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com