Compound technique for producing coal gas by utilizing high-temperature excess heat and high-temperature CO2 waste gas

A coal gasification, high temperature technology, applied in the direction of granular/powder fuel gasification, waste heat treatment, cement production, etc., can solve the problems of high cost, waste of CO2 effective resources, etc., and achieve huge economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

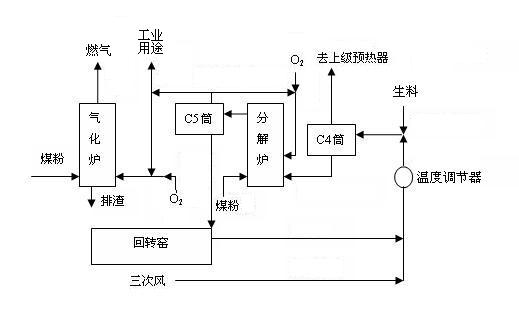

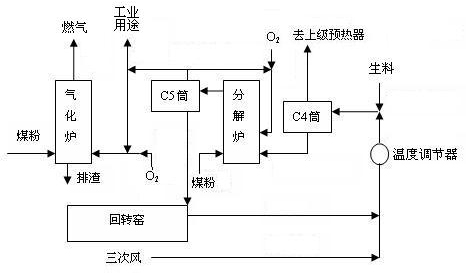

[0016] Concrete steps of the present invention are:

[0017] a. The tail gas of the rotary kiln merges with the tertiary air for combustion in the cement production process, passes through the temperature regulator, and then merges with the raw meal after multi-stage preheating in the pipeline, and enters the C4 cylinder of the cyclone preheater together; The temperature of the tail gas generated in the kiln is 1000℃~1100℃, the temperature of the tertiary air used for combustion in the cement production process is 650℃~800℃, and the temperature after the rotary kiln tail gas is combined with the tertiary air used for combustion in the cement production process is adjusted by the temperature regulator 850℃~860℃.

[0018] b. After preheating in the C4 cylinder of the cyclone preheater, the gas is discharged, or returned to the upper preheater, and the raw material enters the decomposition furnace; the temperature of the raw material out of the C4 cylinder is 750 ° C ~ 770 ° C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com