Expanded perlite fine powder-polymer latex powder composite modified dry mortar

A technology of polymer latex and expanded perlite, which is applied in solid waste management, climate sustainability, sustainable waste treatment, etc., can solve the problems of high polymer cost, obstacles to the popularization and application of dry powder mortar, and high polymer content. Achieve the effect of enhanced construction workability, reduced delamination and bleeding, and less cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A novel expanded perlite fine powder-polymer latex powder composite dry powder mortar admixture comprises the following components by weight percentage:

[0042] Expanded perlite fine powder: 50-75%

[0043] Redispersible polymer rubber powder based on vinyl acetate and ethylene copolymer: 25-50%

[0044] Described a kind of novel expanded perlite fine powder-polymer latex powder composite dry powder mortar admixture is characterized in that the expanded perlite fine powder all originates from the waste flue gas particles collected in the bag filter of the expanded perlite production line. The particles of 0.075mm sieve accounted for more than 90% of the particle size composition.

[0045] When the novel expanded perlite fine powder-polymer latex powder composite dry powder mortar admixture is added to the dry powder mortar, the effective dosage is 15% to 25% of the cement mass.

[0046] Below in conjunction with specific implementation example the present invention i...

Embodiment 2

[0054] Embodiment 2 is except that fine powder, latex powder add-on become 100g, 50g respectively, other is with embodiment 1.

Embodiment 3

[0055] Embodiment 3 except fine powder, latex powder add-on becomes 75g, 75g respectively, other is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

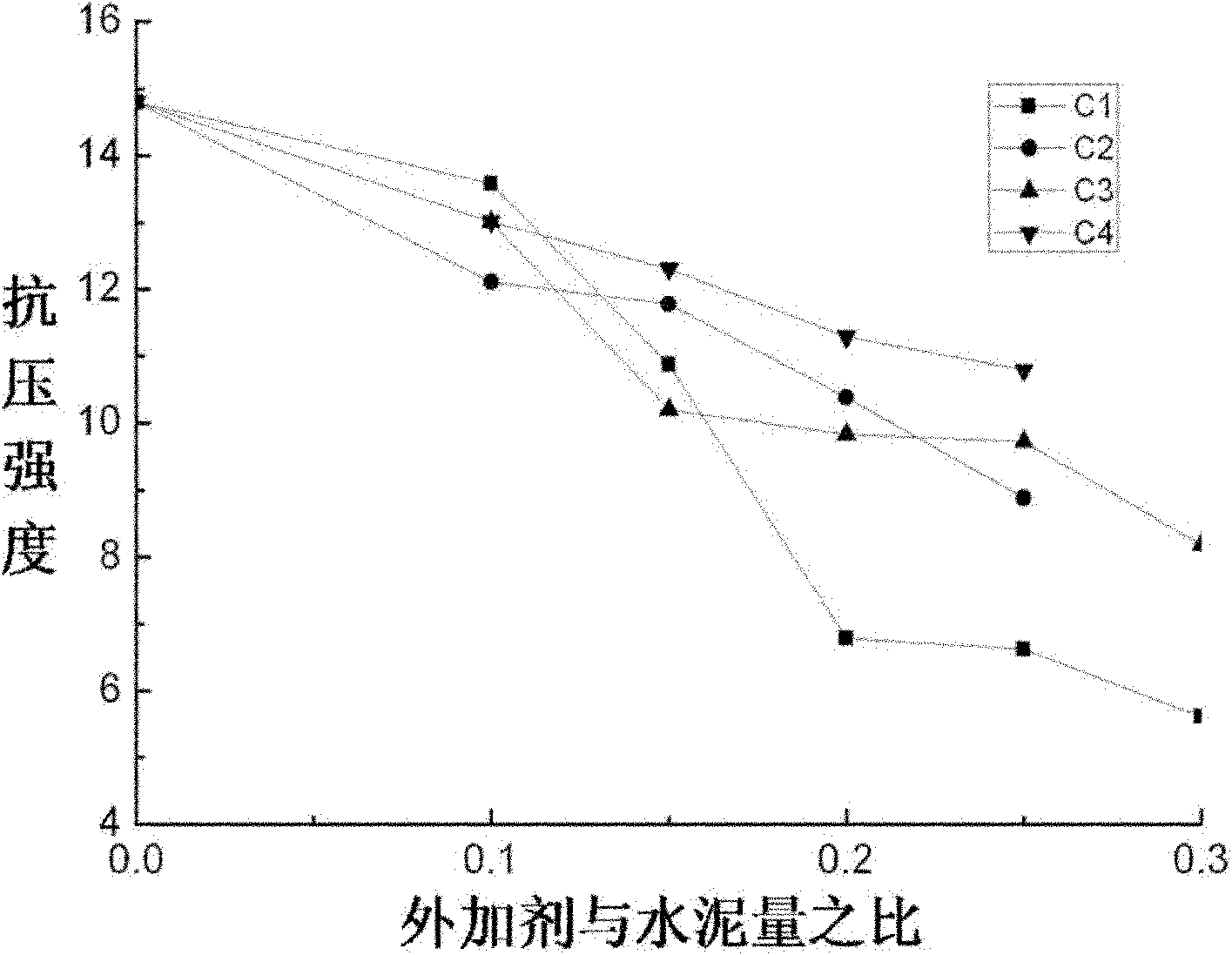

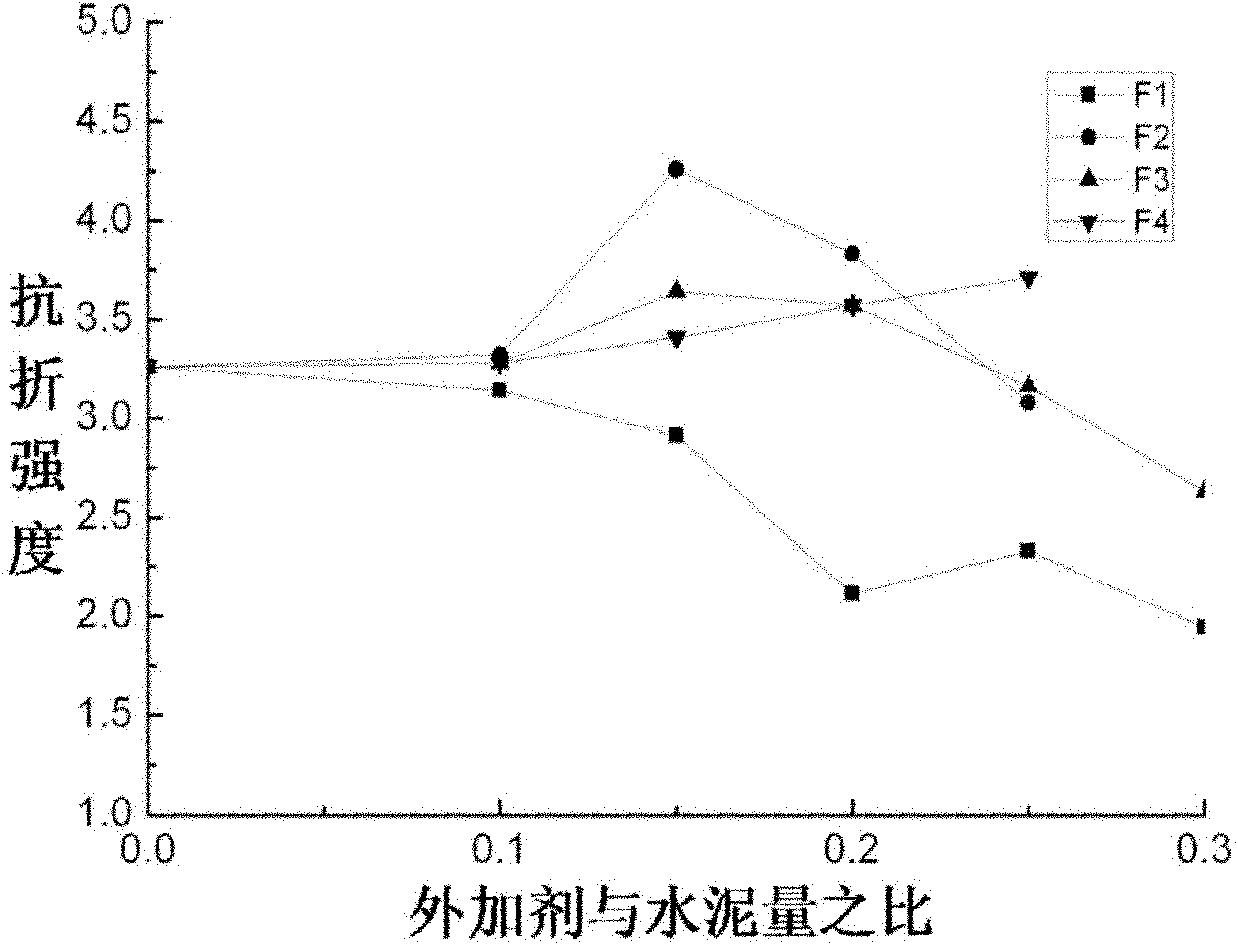

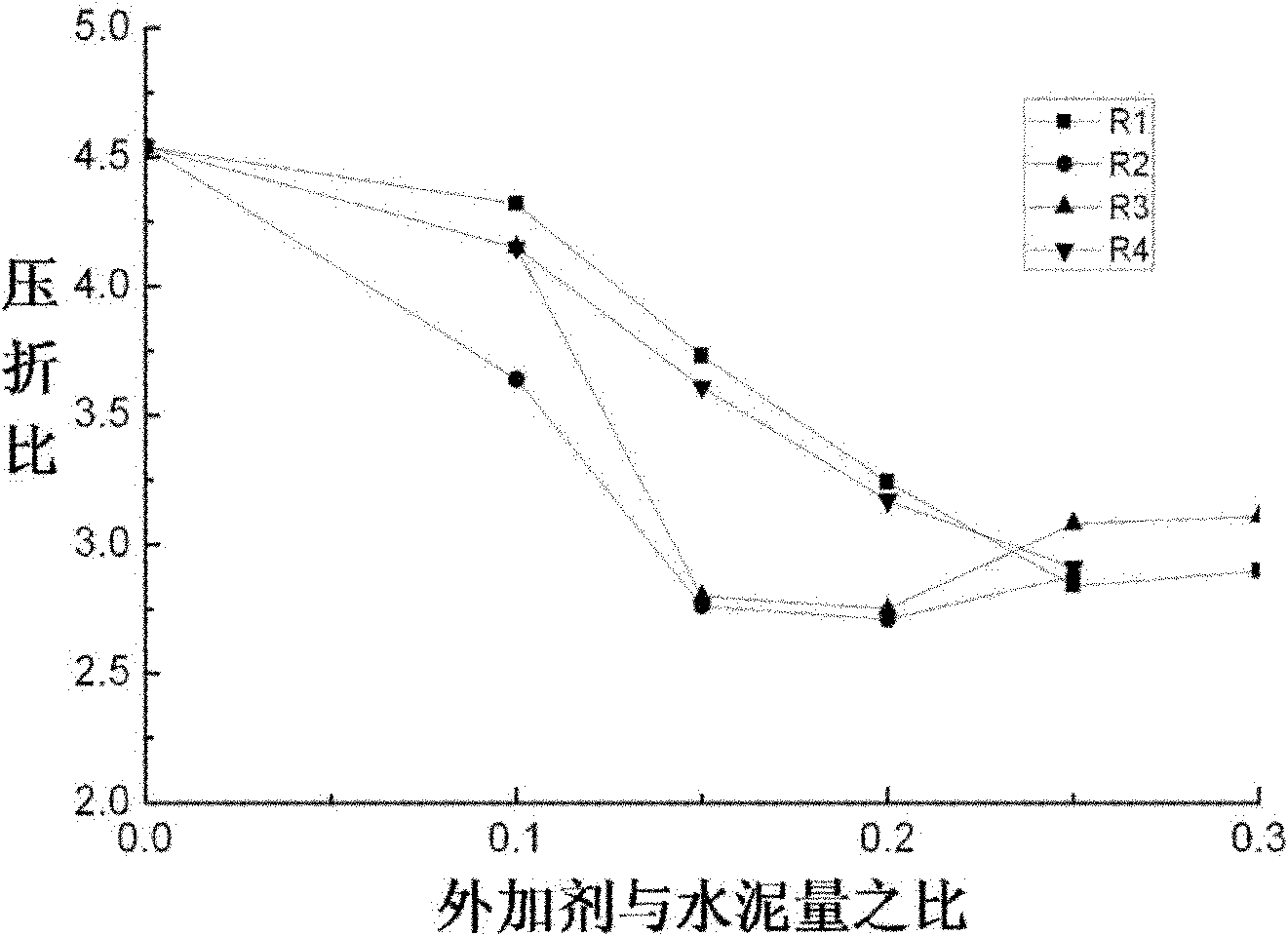

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com